Posted: May 14, 2022 by: Bonnie

SMT assembly refers to the abbreviation of a series of technological processes that are processed based on PCB. PCB (Printed Circuit Board) is a printed circuit board. SMT is Surface Mount Technology (abbreviation of Surface Mounted Technology), which is the most popular technology and process in the electronic assembly industry. It is a circuit assembly technology that mounts leadless or short lead surface mount components (SMC/SMD) on the surface of the printed circuit board, and then solders and assembles them by reflow soldering or DIP soldering.

The advantages of SMT assembly

1. high assembly density, small size, and lightweight of electronic productsThe volume and weight of SMD are only about 1/10 of those of traditional plug-in components. Generally, after SMT is used, the volume of electronic products is reduced by 40%~60%, the weight is reduced by 60% ~80%.

2. High reliability and strong anti-vibration ability.

The soldering defect rate is low. Good high-frequency characteristics. Electromagnetic and radio frequency interference is reduced. Easy to automate and improve production efficiency.

Reduce costs by 30% to 50%. Save material, energy, equipment, labor force, time, etc.

In through-hole assembly, leads are passed through holes to connect components. Since the SMT components are soldered directly on the PCB, the overall build is much simpler.

SMT Assembly process:

1. Programming and setting up the placement machine: According to the BOM pick & place file provided by the customer, program the coordinates of the position of the surface mount components. Then carry out the first production with the SMT assembly processing data provided by the customer.

2. Printing solder paste: The solder paste is stenciled to the pads of the PCB surface to prepare for the soldering of the components. The equipment used is a screen printing machine (printing machine), which is located at the forefront of the SMT assembly processing production line.

3. SPI (Solder paste inspection): The solder paste detector, detects whether the solder paste printing is a good product, whether there is less tin, leaking tin, more tin, and other undesirable phenomena.

4. SMT: Accurately install the electronic components SMD on the fixed position of the PCB. The equipment used is a placement machine, which is located behind the screen printing machine in the SMT production line. The placement machine is divided into the high-speed machine and the general-purpose machine.

High-speed machine: used for components with large pin spacing and small pin spacing.

Universal machine: small pin spacing (pin density), bulky components.

5. Reflow soldering: Mainly, the solder paste is melted at a high temperature, and after cooling, the electronic component SMD and the PCB are firmly welded together. The equipment used is a reflow soldering furnace, which is located behind the placement machine in the SMT production line.

6. Cleaning: Its function is to remove the welding residues such as flux that are harmful to the human body on the assembled PCB. The equipment used is a washing machine.

7. AOI (Automatic optical inspection): Automatic optical detector to detect whether the welded components have poor welding, such as empty solder, etc.

8. Manual inspection: Whether the version of PCBA is a changed version. Whether the customer requires components to use substitute materials or components of designated brands. IC, Diodes, Triodes, Tantalum capacitors, Aluminum Capacitors, Switches, and other directional components whether the direction of the device is correct; defects after welding: short circuit, open circuit, fake parts, and fakes solder.

9. Rework: Its function is to rework the PCB that detects the failure. The tools used are soldering iron, rework station, etc.

What constitutes SMT Assembly Cost:

The price calculation of SMT is generally based on the BOM. Calculate the quantity and type of materials according to the formula.

Item

Calculation

Note

Setup Cost

For first production

Depends on the simplicity of the model

Stencil cost

For first production

Laser drilling, depending on the size of the stencil

Capacitor/Resistor SMD Fee

One point is calculated for each pad of a single resistive element

The package size of components is generally not distinguished

Triode/ SOP patch cost

A single pin calculates a point

There will be differences according to the package size, such as some MOS tubes and other pads are larger

IC chip cost

4 pins calculate a point

BGA type package calculations will be different

Special material patch charges (shield cover, module, card slot, etc.)

Calculate a point according to the size of the material and the difficulty

According to the packaging method, the type of material, and whether it is easy to mount, etc.

Note: Since the SMT process involves a lot of links, many products will be adjusted according to the specific situation.

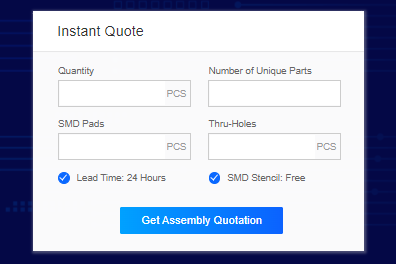

AiPCBA's self-developed product online PCBA flexible intelligent manufacturing platform is committed to providing customers with one-stop PCBA prototype production and mass production services. A one-stop PCBA online quotation tool is provided here. You only need to upload your Gerber and BOM files, and AiPCBA can complete all quotations for you within 20 seconds.

AiPCBA: SMT Assembly Service

AiPCBA focuses on a one-stop service for SMT assembly, PCB production, component procurement, assembly, and testing. It is located in Baoan, Shenzhen. The SMT factory covers an area of about 3,500 square meters, as well as various professional testing equipment. At the same time, It has an experienced and professional manufacturing team and customer service team. There are 5 SMT production lines, equipped with new imported placement machines, eight-temperature reflow ovens, automatic solder paste printers, wave soldering, and other high-end equipment, and equipped with AOI, XRAY, SPI, intelligent solder paste detectors, automatic Sub-board machine, BGA rework station, conformal paint spraying and other equipment, focusing on R&D prototyping, small and mass volume SMT assembly, test assembly and other services. The 48-hour sample delivery rate exceeds 95%.

AiPCBA's one-stop PCBA manufacturing service has been widely used in AI artificial intelligence hardware, communication equipment, automotive electronics, industrial control, security, medical, Internet of Things, new energy, rail transit, and other fields; we meet customers with personalized manufacturing and flexible manufacturing Service requirements for hardware PCBA circuit boards from samples, small and medium batches to mass production.

|

Item |

Stencils Capabilities |

Remarks |

|

Maximum Cutting size |

610mm*600mm |

|

|

Maximum template size |

600mm*800mm |

|

|

Cutting speed |

1-50 mm/s |

|

|

Cutting thickness |

20um~300um |

|

|

CPH |

8000 Hole/H |

|

|

Laser type |

Ytterbium fiber laser |

|

|

Wavelength |

1070 nm(IR) |

|

|

Machine accuracy |

±1.5μm |

|

|

Item |

SMT Capabilities |

Remarks |

|

Maximum size |

900x800mm |

pcb patch size |

|

Minimum size |

20x20mm |

pcb patch size |

|

Patch size |

70x70mm Square chip |

Maximum component placement size |

|

Patch size |

01005(0.4x0.2mm) |

Minimum component placement size |

|

Patch type |

360 kinds |

|

|

CPH |

40000 |

Placement speed per hour |

|

Mounting accuracy |

±0.02mm |

|

|

Mounting minimum pitch |

0.20mm |

Equipment placement minimum spacing components |

How to get the Price or Order in AiPCBA?

Upload your Gerber file in our online quotation platform:PCB files should be provided when you need PCB assembly services. AiPCBA accepts Gerber files (RS-274-X), PCBDOC, PCB, Eagle file and etc. These listed files are required for PCB fabrication, testing, and stencil production; and will also be used to test the boards after soldering is completed.

Your BOM suggest include:

- Reference designators

- Quantity of each part

- Manufacturer part number

- Part description

- Type (SMT, Thru-Hole, Fine-pitch, BGA, etc.).

- Package description (QFN32, SOIC, 0805, etc. package is very helpful but not required).

This data will be used in the PCBA production process by an automatic PCBA machine. It should contain the following info:

- Surface Legend (top or bottom)

- X/Y coordinate of the center of the part (centroid data)

- Part number

- Rotation (theta)

In order to assemble your PCB smoothly, you could offer us some documents like 3D design files, schematics, etc. to guide our PCBA process.

You can also send PCB Gerbers, BOM files, and specifications to sales@aipcba.com, and get an exact quotation within 24 hours. AiPCBA provides the fastest 3 days of PCBA prototyping services (including PCB prototype, BOM parts sourcing, surface mounting assembly, testing), free DFM inspection, components replacement suggestions, packaging of static bag & bubble bag & carton safe. Ensure your PCB design can be effectively verified, and quickly meet the small batch to mass production Assembly requirements.

Quote it now with AiPCBA online quote platform.