Posted: May 14, 2022 by: Simple

In the SMT assembly stage, in order to get a high-quality and high-reliability product, you may encounter the following questions: What is SMT assembly? What is the SMT assembly process? What are the SMT assembly processes ? How to find a suitable SMT assembly service? This article by AiPCBA will help you solve the above doubts.

What is SMT assembly?

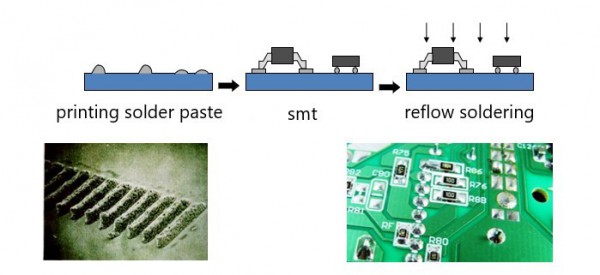

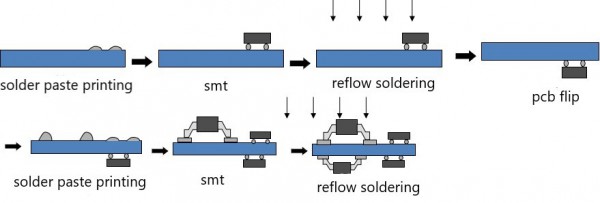

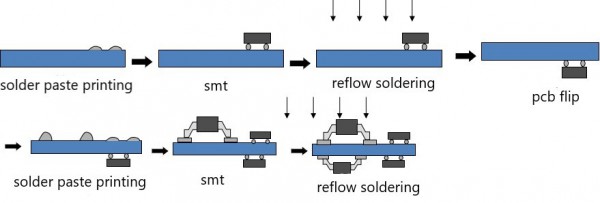

In an easy-to-understand way, SMT assembly is a soldering technology that mounts chip components on a PCB board through a reflow soldering process or other processes.Due to the different complexity of the product, it is usually divided into single-sided SMT assembly and double-sided SMT assembly.

Single-sided SMT assembly

The single-sided SMT assembly uses a single-sided PCB , the design process is simple, and the functions implemented are relatively simple, generally suitable for some relatively simple functional circuits.Double sided SMT assembly

The double-sided SMT assembly uses a double-sided PCB. One side has a large IC period, and the other side is mainly composed of chip components. The design process is relatively complex, and the functions to be realized are also relatively complex.SMT assembly process

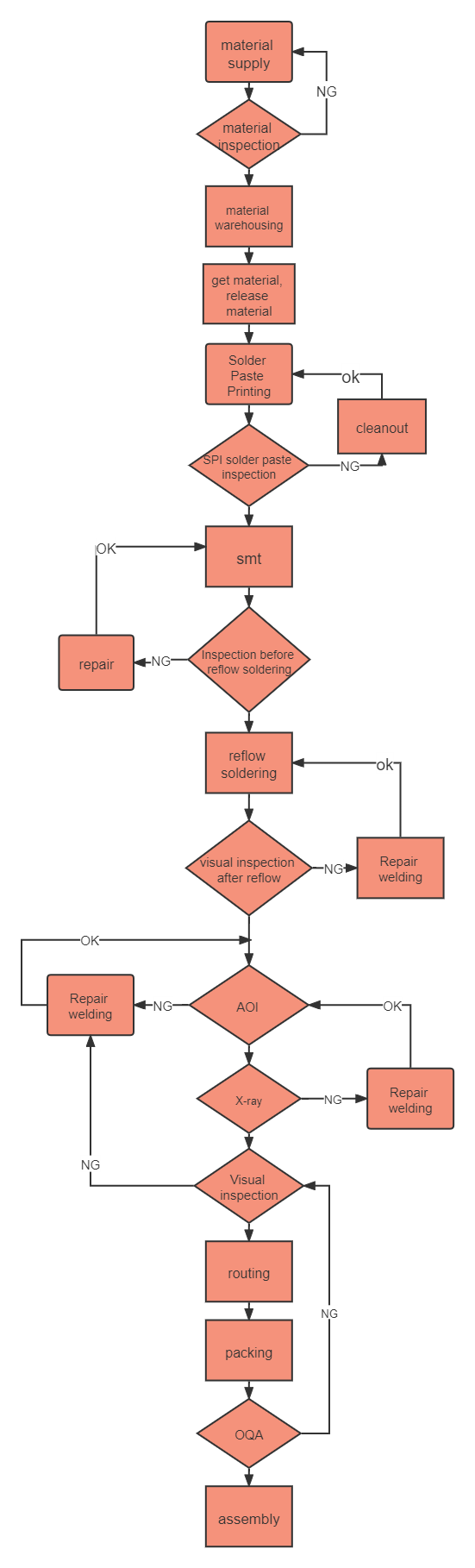

In order to facilitate your understanding, I will use a flowchart to show the SMT assembly process.The SMT assembly process can be divided into the following main parts: printing solder paste, solder paste inspection, SMT, reflow soldering, inspection.

Printing solder paste during SMT assembly

Printing solder paste is one of the most important processes in the SMT assembly process. AiPCBA uses an automatic printing machine, adopts the method of stencil printing, and prints the solder paste to the position corresponding to the PCB pad through the movement of the squeegee.

Solder paste inspection during SMT assembly

The amount of solder paste is also a very important process. Too much or too little solder paste will affect the quality of the product. AiPCBA uses SPI equipment to detect solder paste, which can perform 100% 3D inspection of solder paste.

SMT during SMT assembly

SMT patching is mainly done by automatic placement machines.The automatic placement machine has set the program in advance to set the XY position of each component on the circuit board, which can ensure that the machine can accurately take out the components from the specified position and accurately install them in the correct position.

Reflow soldering during SMT assembly

Reflow soldering is the most important process in the SMT assembly process. In this process, the most important thing is the setting of the temperature curve of the reflow soldering machine. For the setting of the temperature curve, AiPCBA is completed by professional engineers. The engineer sets the temperature curve according to the physical and chemical changes of the solder paste during the reflow soldering process. Welding defects can be reduced, thereby improving production quality and efficiency.

Inspection during SMT assembly

The inspection of AiPCBA is mainly AOI inspection, X-ray inspection and visual inspection. 100% inspection can greatly improve the quality of products. AOI inspection is mainly to detect different placement errors and welding errors, X-ray inspection is mainly to detect internal problem areas without damaging the object to be tested, and visual inspection is mainly to detect product appearance errors.

In the SMT assembly process, there are some differences between single-sided SMT assembly and double-sided SMT assembly.

Single-sided SMT assembly process

Double-sided SMT assembly process

Double-sided SMT assembly process

Choose a suitable SMT assembly service

Choose a suitable SMT assembly service

There is no perfect SMT assembly service, only more suitable SMT assembly service. Choosing a suitable SMT assembly service can improve the efficiency and reliability of SMT assembly. Here are the points you need to pay attention to:

PCB manufacturing in SMT assembly

The quality of PCB affects the quality of SMT assembly, especially the materials for PCB manufacturing. Generally speaking, SMT assembly proofing and SMT assembly mass production are definitely different for the quality of PCB manufacturing. You can choose the right manufacturer according to your product requirements.SMT assembly process

The SMT assembly process is one of the most important factors affecting the quality of SMT assembly. Stencil quality, solder paste preservation, solder paste printing, solder paste inspection, temperature curve setting of reflow soldering equipment, AOI, X-ray inspection, etc., you cannot ignore the points mentioned above.Material inventory in SMT assembly

Materials are an essential part of SMT assembly, which determines the production efficiency of your products. There are many SMT assembly service in the market that provide material supply and material procurement, but some service have insufficient material inventory, insufficient material types, and materials that are not genuine, which will lead to longer production cycles of products, so you must choose carefully. You can try AiPCBA.

Accuracy of SMT assembly equipment

A variety of instruments are used in the SMT assembly process. Generally speaking, the higher the precision of the equipment, the higher the stability and stability of the product. The precision of SMT assembly equipment reflects the strength of service. AiPCBA uses high-precision equipment, which improves efficiency on the premise of ensuring product quality.SMT assembly price

The price of SMT assembly affects the cost of the product. You can use online quotations and multiple SMT assembly service to price, so that it is easier to find SMT assembly service that meet your budget. AiPCBA provides SMT assembly pricing service, with high pricing efficiency, all information is kept confidential, don't worry.

SMT assembly on-time delivery rate

The delivery speed of SMT assembly is not as fast as possible. The complexity of SMT assembly, the quantity of SMT assembly, and the requirements of SMT assembly will affect the delivery speed of SMT assembly. What you need to pay attention to is the on-time delivery rate, which can prove A credit rating from SMT assembly service.

The above 5 points are what you need to pay attention to when choosing SMT assembly services.

With the advancement and development of current technology, in order to improve the production efficiency and quality of products, most customers are more inclined to hand over PCB boards, materials, and SMT assembly directly to service, which can maximize efficiency.

In order to meet the needs of customers, many SMT assembly service provide turnkey-PCB-assembly services, and AiPCBA is such a manufacturer.

AiPCBA has accumulated more than 6 years in the electronics industry, and has strong professional strength, serving more than 2 million customers around the world, with 99% customer satisfaction, 99% qualified products, 98% on-time delivery rate, and an average saving of 250,000 R&D costs per week for customers.

There is no perfect SMT assembly manufacturer, there are only more suitable SMT assembly service. If you need it, try it out, AiPCBA will not let you down, every SMT assembly is 100% attentive.