Posted: December 20, 2021 by: Bonnie

BOM is the bill of materials, called product structure table or material structure table, which records in detail all the materials and related attributes used in the project. In the management BOM system, materials are the collective name of all production-related materials such as products, semi-finished products, work in progress, raw materials, supporting parts, collaborative parts, and consumables.

According to the purpose, the product has to go through three stages: engineering design---process manufacturing design----production manufacturing. In this process, many BOMs are generated, such as engineering BOM (EBOM), planning BOM (PBOM), design BOM (DBOM), manufacturing BOM (MBOM), purchasing BOM (purchasing BOM), etc. These BOMs contain much different Content.

1.The composition of BOM

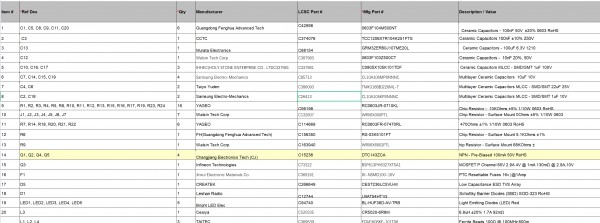

The most primitive BOM includes material code, component name, component usage, component unit, etc. Other BOMs will add corresponding information according to different purposes, such as production BOM, and also need to include process level, production attributes, and other information.

The material code is the code that uniquely identifies the material, usually represented by a character string (fixed length or variable length) or a number, and the material code is the unique identification code for the material by the computer system. It uses a set of codes to represent a material. The material code must be unique, that is, one material cannot have multiple material codes, and one material code cannot correspond to multiple materials of different specifications.

The names of the components are resistors, capacitors, diodes, transistors, etc. These are the names of the components.

The amount of components, such as 2 resistors and 10 capacitors, is as much as needed.

The unit of components, for example, the unit of resistance is the ohm, and the unit of capacitance is farad.

2.The purpose of BOM

The main uses of BOM include quotation reference, computer identification of material basis, procurement and outsourcing basis, cost calculation, material traceability, matching, and material requisition basis, etc.

3.Classification of BOM

From the structural point of view, BOM can be divided into single-layer BOM and multi-layer BOM. A single-level BOM defines the direct components and quantities that constitute a product, and a multi-level BOM is the complete structure of the product, which is composed of multiple BOMs.

Single-layer BOM: defines the direct components that make up the product. Components can be raw materials or semi-finished products, and semi-finished products also have their BOM.

Multi-layer BOM: It is a tree structure that constitutes the complete structure of the product, including multiple BOMs, and the lower-level BOM is a self-made semi-finished product within the enterprise. BOM can contain multiple levels, such as "raw materials -> semi-finished products 1-> semi-finished products 2-> semi-finished products 3-> finished products", including a total of 4 levels of BOM.

4.The importance of BOM

BOM is an indispensable document for receiving customer orders, selecting assembly, preparing production and purchasing plans, supporting material picking, tracking logistics, tracing tasks, calculating costs, and changing cost designs. The accuracy of BOM directly affects the inventory of raw materials and parts.

Consequences of incorrect BOM: increased inventory, blocked production, low efficiency, unguaranteed delivery time, increased costs, and difficulty in coordination among various departments, Impact on morale, waste of resources, etc. cause enterprise chaos, BOM is the basis of enterprise internal communication and coordination.

5.The Management of BOM

Traditional BOM management is a manual mode, mainly using Excel spreadsheet tools to manage the BOM, manually inputting raw material information, and printing it into paper documents for approval by different departments.

The current management BOM can realize the seamless flow of BOM between different departments, ensure the accuracy of BOM information and the timeliness of approval, and also realize the real-time follow-up of the whole process of BOM, by generating multiple different BOM versions and highlighting Display different components and easily realize cost monitoring.

6.BOM quotation procurement

The format of the BOM is different, and the content contained is also different. If the BOM file is identified in this way, it will not only take time but also be inaccurate. AiPCBA has a unique algorithm and standard BOM template for this problem. The user uploads the BOM. After that, the system automatically converts the standard format, so that information can be obtained accurately and intuitively, and there will be no confusion or incorrect BOM.

AiPCBA's quotation and procurement process are simple and easy to use. Customers only need to register and log in, upload the BOM file, and AiPCBA can automatically allocate orders in 30 seconds. The BOM table and platform big data are automatically matched. The efficiency of BOM allocation is the first in the industry.

Including matching brand/channel, delivery date, unit price, subtotal and other information, each piece of material is original and authentic. There will also be complete matching, smart recommendation, no matching, especially discontinuation prompts and BOM abnormal prompts. This can avoid common procurement errors, effectively correct replacement materials, and avoid batch material shortages.