Posted: May 14, 2022 by: Bonnie

- How to find a cheap PCB manufacturer & Assembly for the prototype?

- How to make a PCB assembly option on turnkey, partial, or user supply?

- No 2oz copper with my current assembly supplier, any reliable alternatives?

- Any recommendation for choosing a proper manufacturer of PCB assembly service?

- How to find some of the components which are out of stock and your PCB assembly factory couldn’t buy it ?

- Looking for PCB fabrication and assembly for through-hole PCB, but where can find it?

1. Services of PCB assembly Manufacturer

Full Turnkey Assembly

Full turnkey PCB assembly service (one-stop PCB assembly) can offer one-stop service from PCB manufacturing, BOM sourcing, PCB assembly, SMT, THT, PCBA testing, product assembly, packaging, and delivery. You are not responsible for supplying any parts on this process and just need to deal with your design while suppliers take care of the rest. But how does the manufacturer offer the full turnkey assembly service?

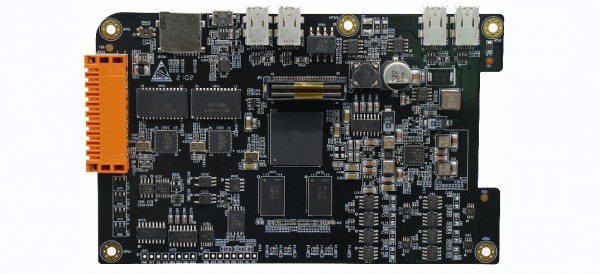

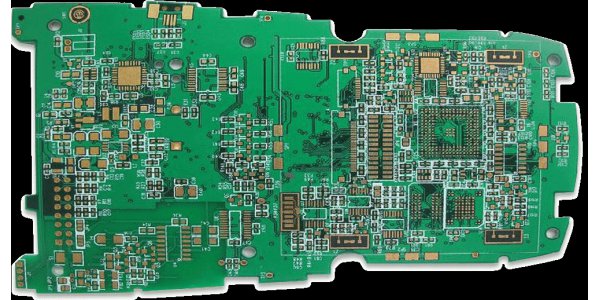

PCB manufacturing: The first step to offer the full turnkey assembly service, you should ensure you can produce or supply the base printed circuit boards for the whole production. AiPCBA has its PCB factory to produce single to multi-layer printed circuit boards. Also, the manufacturing capability in AiPCBA can meet most of the printed circuit boards such as rigid PCB and flex+ rigid PC, 1-20 layer, 0.5-12oz copper thickness, 0.2-5.0mm boards thickness, all kinds of surface treatment. Also, some turnkey assembly manufacturers haven’t their PCB factory, but they have the cooperate PCB factory to accept their PCB manufacturing order.

Components sourcing: Offering the turnkey assembly, the critical part is that they can purchase all of the components on your design. And ensure the component quality is with a guarantee. Which needs a strong supplier to support the assembly manufacturer to meet this requirement. If you order in AiPCBA, I think you do not need to worry about this kind of problem. Because AiPCBA has an intelligent spot material storage warehouse, as well as a constant temperature and humidity warehouse, more than 200,000 kinds of components are available in stock. Whether it is a prototype, small-batch production, or mass production, their factory warehouse can directly issue materials to the production line, reducing the waiting time and receipt of purchased materials. In addition to its standing materials, AiPCBA also connects with global distributors Digikey, Mouser, Arrow, RS, etc., as well as the API interface of spot inventory data of more than 800 domestic spot suppliers in China, to grasp the advantageous channels of material supply and inventory changes in real-time. Quality is guaranteed.

Partial turnkey Assembly

If you don’t need the full turnkey assembly manufacturing service because you can offer some parts of your products such as printed circuit boards, some important components, or some parts that are in your stock, you can find the assembly manufacturer who can offer the partial turnkey assembly. AiPCBA not only can offer the full turnkey assembly manufacturing service but also accept the need for partial turnkey assembly from their customer. You just need to send your parts to the AiPCBA warehouse, then they will help procure the rest of the parts and organize the production for your design. Also if you offer the component for this partial assembly to AiPCBA, AiPCBA has a 500-square-meter professional component testing laboratory and a professional testing engineer team, which supports component electrical performance, package opening, X-Ray testing, anti-counterfeiting testing, and another professional testing to ensure that each of your components is qualified quality and from genuine sources.

Consigned Assembly (Kitted)

In this type of assembly, the customer provides all parts to the manufacturer for assembly. Components to be supplied include bare printed circuit boards, electronic components, and all necessary PCB design files, and the manufacturer will assemble the components using their equipment. This type of PCB assembly is also known as a commissioned PCB assembly. But if there is any problem occur, the customer need bear all responsibility, because all of the parts are supplied by themselves. And they can make sure all of the bare printed circuit boards and the components are 100% no problem in the road.So whatever full turnkey assembly, partial turnkey assembly, or Consigned assembly, is based on your decision and your cost and time need.

2.The step of choosing a PCB Assembly Manufacturer

Convert your design draft to PCB gerber file, export BOM list and pick&place file.

Converting design files is a key step in getting your product to market. Because the production of the product by the manufacturer of the PCB assembly is based on the Gerber file of the PCB. To avoid the risk of misunderstanding between your PCB design files and manufacturers, it is best to prepare a suitable file format in advance, which is also a key step for your subsequent quotation from suppliers.

Confirm what kind of assembly service you need

Before you choose a PCB assembly manufacturer, please think about your situation and confirm what kind of assembly service you need. For example, if you are the first time issuing a product and you do not have enough experience in manufacturing, you should find a full turnkey assembly manufacturer. Or if you are issued a prototype manufacturing, you are hard to buy some components with limited quantity, in this case, the full turnkey assembly manufacturer can help you solve this problem.

The certifications of PCB assembly manufacturers

Many PCB assembly manufacturers have used ISO 9001, ISO14000, ISO/TS16949 standards to ensure that their services and products meet regulatory and industry-wide quality standards. ISO sets guidelines for meeting customer expectations by providing quality services and products to companies around the world. Also, UL Certification is dedicated to creating a safe working and living environment. UL regularly updates safety standards for products used in different commercial and industrial sectors. You should know what kind of certifications should be needed according to your product. All PCBs in AiPCBA are produced based on UL and ISO certification standards. All our normal specification PCBs are strictly obeying to IPC-A-6011/6012 Class 2 latest version and IPC-A-600 Class 2 latest version.

Assess your project start-up cost and lead time

After you realize what assembly service you need, you should be concerned about your project start-up cost and the lead time in your schedule. You need a quick lead time with high cost or a slow lead time with low cost. According to your need to find your target manufacturer.

Get in touch with the PCB assembly manufacturer

When you have completed all the above steps, you can start contacting the supplier in your mind. Most manufacturers support you to contact them by email on their website. But the current trend is that many manufacturers will use the online quotation tool to let customers try to know their manufacturing cost and get in touch after you have some operations on the website. Which can improve the interactions with the customer. For example, on the AiPCBA website, you can find the PCB instant quote, PCBA assembly quote, Parts sourcing quotes. You just need to upload your PCB Gerber file, BOM list then you will get the complete quotation for your design. It is very convenient for the engineer to check their design production budget.

3.Why choose a turnkey PCB assembly service in AiPCBA?

Save time and cost

Turnkey PCB assembly manufacturing can help you save worry and workload. The one-stop service in AiPCBA, the most basic advantage is high efficiency and low cost. You do not need to purchase materials by yourself, manage PCBA production projects by yourself, or connect with multiple suppliers. You only need to safely hand over the production data to AiPCBA, and you can get your PCBA circuit board in about a week. No matter what stage your product is in, as long as you hand over the production data to us, AiPCBA will complete the rest of the production of components supply, PCB production, and PCBA processing.

Rapid BOM quote and sourcing capability

AiPCBA uses Electronic Components Ai Matching to get an online quote in 30s target. In terms of components, AiPCBA has an intelligent spot material storage warehouse, global supplier authorization certification, a professional technical support team, and an advanced component testing laboratory. And based on the big data of the components, the risk management of the materials is carried out, and the risk assessment of the BOM materials based on the big data is also carried out.

High quality PCBA flexible manufacturing capability

AiPCBA implements a customized PCBA flexible manufacturing production line, a quality management system that monitors the whole process, conducts project engineering pre-qualification based on big data and artificial intelligence, and achieves visual 3D PCBA DFM engineering pre-qualification. Customized SMT production lines for PCBA flexible manufacturing, AiPCBA's prototype production lines all use EUROPLACER high-precision SMT production equipment and use IOT Internet of Things technology to make SMT production equipment highly coordinated with MES system, which can complete the processing needs of customer PCBA prototype with high quality. Specialized in providing services for you who need flexible production custom production lines, so that you no longer pay high costs for proofing and small batch production.The above is the ability of the AiPCBA team to create value for customers. AiPCBA will adhere to technology-driven, big data, and artificial intelligence-driven intelligent manufacturing, to help customers quickly deliver PCBA products, put them on the market quickly, and quickly accomplish product value.