Propose of immersion copper

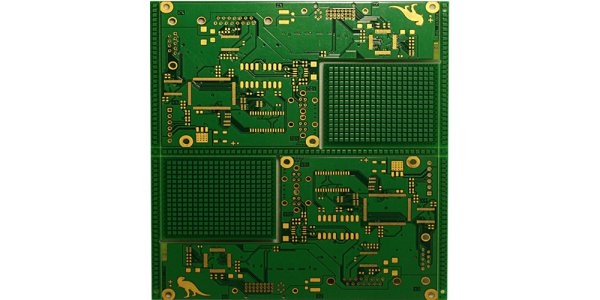

The purpose of sinking copper is to use a chemical reaction principle to add a layer of 0.3um-0.5um copper in the hole, so that the originally non-conductive hole has conductivity, so that the subsequent plate plating and pattern plating can be carried out smoothly to complete the PCB The electrical interconnection between the circuit boards. Immersion copper is also divided into thick copper and thin copper.

Advantages and disadvantages of immersion silver

Even if exposed to heat, humidity and pollution, silver can still maintain good solder-ability, but will lose luster. Silver deposition does not have the good physical strength of electroless nickel / gold deposition because there is no nickel under the silver layer.

Advantages: simple process, suitable for lead-free welding, SMT. Very flat surface, low cost, suitable for very fine lines.

Disadvantages: high storage requirements, easy to pollute. The welding strength is prone to problems (micro void problem). It is easy to have electro-migration and Galvanic effect undercut with copper under solder mask. Electrical measurement is also a problem.

Process of immersion silver and immersion copper

Immersion silver is divided into the following three steps: pre-preg, immersion and final deionized water washing. There are three purposes for the establishment of pre-preg. One is to use it as a sacrificial solution to prevent the copper and other substances from being contaminated by the micro-etching tank to contaminate the silver deposit. The same chemical environment and pH value in the silver solution. Since the composition of the pre-preg is the same as the silver sink (except for metallic silver), the third function of this process is to automatically replenish the silver sink. The only thing consumed in the immersion silver reaction is metallic silver. The change in the content of the organic components in the immersion silver solution is only the loss caused by the bath liquid, and the pre-preg and the immersion silver solution have the same composition. The amount is equal to the amount brought out by the silver sink, so the silver sink liquid will not accumulate unnecessary organic matter. The silver sink reaction is carried out by a substitution reaction between copper and silver ions. The copper surface that has been micro-roughened by the micro-etching solution can ensure that a uniform and consistent silver deposit layer can be slowly generated at a controlled silver deposit speed. The slow silver deposition speed is conducive to depositing a dense crystal structure, avoiding the growth of particles due to precipitation and agglomeration, and forming a high-density silver layer. This compact structure and moderate thickness (6-12u") silver layer not only has high corrosion resistance, but also has very good electrical conductivity. The silver sink solution is very stable, having a long life cycle, and insensitive to light and trace halide.

The process of sinking copper requires rough grinding, expansion, removal of slag, tertiary water washing, neutralization, secondary water washing, degreasing, dilute acid washing, secondary water washing, micro-etching , Pre-dip, activation, secondary water washing, acceleration, primary water washing, copper sinking, secondary water washing, plate electroplating, fine grinding, copper inspection. These are the full process of immersion copper.