Immersion Copper PCB

Posted: May 14, 2022

By: Bonnie

Immersion copper

Immersion copper is abbreviated as (Eletcroless Plating Copper), also known as plated through hole, and abbreviated as PTH, which is a self-catalyzed oxidation-reduction reaction. PTH process is needed after drilling two or more layers of plates.

Function of PTH: A thin layer of chemical copper is deposited on the non-conductive pore wall substrates drilled by chemical method to serve as the back electroplated copper substrates.

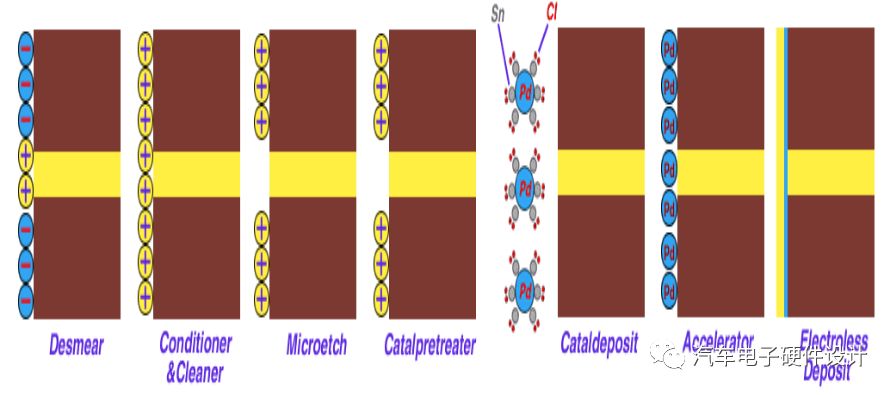

Detailed process of PTH:

1. Alkaline degreasing:

Remove oil stains, fingerprints, oxides and dust in the hole; adjust the hole wall from negative charge to positive charge, so as to facilitate the adsorption of colloidal palladium in the later process; clean after oil removal strictly according to the requirements of the guidelines, and test with copper backlight.

2. Microerosion:

Removal of oxide from the surface, coarsening the surface, ensuring a good adhesion between subsequent deposited copper layer and base copper; the new copper mask has a strong activity, can adsorb colloidal palladium well;

3. Pre-immersion:

It mainly protects the palladium cell from the contamination of the pretreatment bath and prolongs the service life of the palladium cell. Besides palladium chloride, the main component is the same as that of the palladium cell, which can effectively wet the pore wall and facilitate the subsequent activation liquid to enter the pore in time for sufficient and effective activation.

4. Activation:

After adjusting the polarity of alkaline deoiling by pretreatment, the charged pore wall can effectively adsorb enough colloidal palladium particles with negative charges to ensure the evenness, continuity and compactness of subsequent copper precipitation. Therefore, deoiling and activation are very important to the quality of subsequent copper precipitation. Control points: the prescribed time; standard stannous ion and chloride ion concentration; specific gravity, acidity and temperature are also important, which should be strictly controlled in accordance with the operating instructions.

5. Degumming:

Removal of tin ions encapsulated in colloidal palladium particles can expose palladium nuclei in colloidal particles and directly and effectively catalyze the chemical precipitation of copper. Experience has shown that fluoroboric acid is a better choice as a defoamer.

6. Copper precipitation:

The activation of palladium nucleus can induce the autocatalytic reaction of chemical copper precipitation. The new chemical copper and hydrogen, the by-product of the reaction, can be used as catalysts to catalyze the reaction, so that the copper precipitation reaction continues. After this process, a layer of chemical copper can be deposited on the plate or hole wall. During the process, the tank liquid should be stirred with normal air to produce more soluble bivalent copper.

The quality of copper sinking process is directly related to the quality of the production line board. It is the main source of the process which is not open through holes and short circuit. It is not convenient for visual inspection. The later process can only be screened by destructive experiments, and can not effectively analyze and monitor a single PCB board. Therefore, once problems arise, batches are inevitable. Quantitative problems, even testing can not be eliminated, the final product caused great quality risks, can only be scrapped in batches, so strictly in accordance with the parameters of the operation instructions.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

12

)

12

7638

1

Share to: