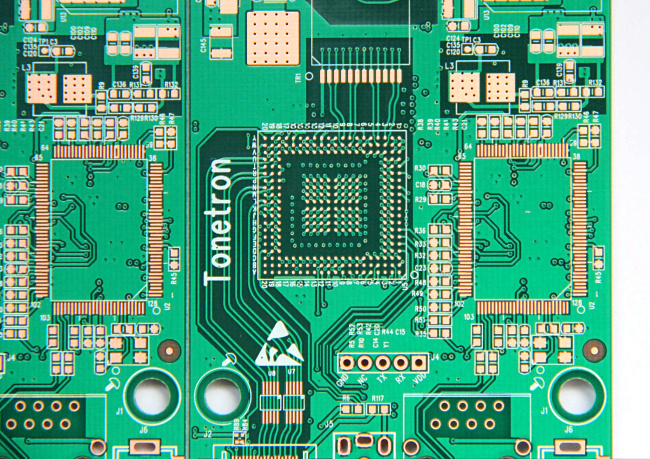

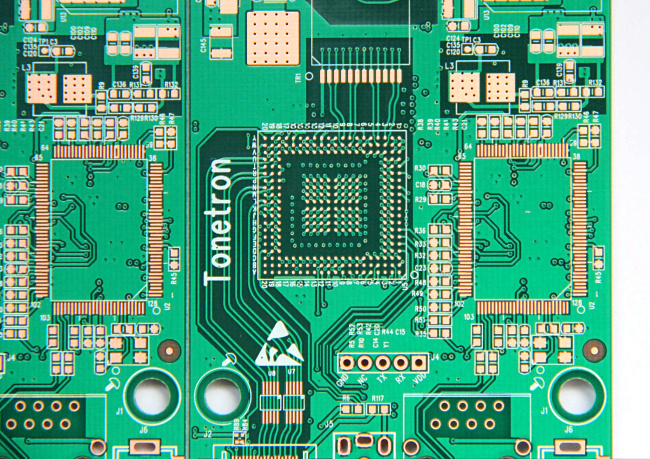

PCB Design Software Process

Posted: May 14, 2022

By: Bonnie

The pcb design software flow is divided into seven steps: netlist input, rule setting, component layout, wiring, inspection, copy board, and output.

2 Rule settings

3 Component layout

4 Wiring

5 PCB design check

6 Review

7 Output

Speed) and the power layer (Plane), these items can be selected by Tools->Verify Design. If a high speed rule is set, it must be checked, otherwise this item can be skipped. Check for errors and you must modify the layout and routing.

Contents

1 Netlist input2 Rule settings

3 Component layout

4 Wiring

5 PCB design check

6 Review

7 Output

Netlist input

There are two ways to input the netlist. One is to use PowerLogic's OLE PowerPCB Connection function, select Send Netlist, and apply OLE function. You can keep the schematic and PCB design consistent at all times to minimize the possibility of error. Another method is to load the netlist directly into the PowerPCB, select File->Import, and enter the netlist generated by the PCB design schematic.Rule setting

If you have already set the PCB design rules in the PCB design schematic design stage, you don't need to set these rules anymore, because when you enter the netlist, the design rules have been entered into the PowerPCB with the netlist. If the design rules are modified, the schematic must be synchronized to ensure that the schematic and PCB are consistent. In addition to design rules and layer definitions, there are some rules that need to be set, such as Pad Stacks, which need to modify the size of standard vias. If the designer has created a new pad or via, be sure to add Layer 25.

Component layout

After the PCB design netlist is input, all the components will be placed at the zero point of the work area and overlapped. The next step is to separate these components and arrange them neatly according to some rules.Wiring

There are also two ways to design and route PCBs, manual routing and automatic routing. The power wiring provided by PowerPCB is very powerful, including automatic push, online design rule checking (DRC), and automatic routing is performed by Specctra's routing engine. Usually these two methods are used together. The common steps are manual-automatic-manual.

PCB design check

Projects have Clearance, Connectivity, and High Speed Rules (High)Speed) and the power layer (Plane), these items can be selected by Tools->Verify Design. If a high speed rule is set, it must be checked, otherwise this item can be skipped. Check for errors and you must modify the layout and routing.

Review

Review according to the "PCB checklist", including design rules, layer definition, line width, spacing, pad, via settings; also focus on reviewing the rationality of device layout, power, ground network routing, high-speed clock network The wiring and shielding, the placement and connection of decoupling capacitors, etc. If the PCB design review fails, the PCB designer should modify the layout and wiring. After passing the test, the reviewer and the PCB designer will sign separately.Output

The PCB design can be output to a printer or output illuminating file. The printer can print the PCB layer by layer, which is convenient for designers and reviewers to check; the lithography file is handed over to the board manufacturer to produce the printed board. The output of the light painting file is very important, which is related to the success or failure of this design.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

11

)

11

877

1

Share to: