The PCB substrate consists of three main components: Cooper Foil, Reinforcement, and Epoxy. Since the Lead Free process started, the fourth item Fillers has been added to the PCB board in large quantities for improve the heat resistance of PCB.

1. Uses, characteristics and precautions of four PCB materials

1.1. Copper FoilElectric Circuit: Conductive line.

Signal line: The signal line for sending messages.

Vcc: power plane, working voltage. The working voltage of the earliest electronic products was mostly set to 12V. With the evolution of technology and power saving requirements, the working voltage has gradually changed to 5V and 3V. Now it is gradually moving to 1V, and the requirements of copper foil are also increasing The higher.

GND (Grounding): Ground plane. Vcc can be thought of as a water tower in the home. When we turn on the faucet, electrons will flow out through the working voltage of the water, because the electronic parts are determined by the flow of electrons. GND can be thought of as a sewer. All used or unused water flows through the sewer, otherwise the faucet will always drain and the house will be flooded.

Heat Dissipation (due to high thermal conductivity): For heat dissipation. Most electronic components consume energy and generate heat. At this time, a large area of copper foil needs to be designed to release the heat into the air as soon as possible.

1.2. Reinforcement

Most PCB reinforcements are made of GF, Glass Fiber. The material of GF, Glass Fiber is a bit like a very thin fishing line.

High Stiffness: It has high "rigidity", making PCB difficult to deform.

Dimension Stability: With good dimensional stability.

Low CTE: It has a low "thermal expansion rate" to prevent the circuit contacts inside the PCB from detaching and causing failure.

Low Warpage: Has a low amount of deformation, that is, low plate bending and plate warping.

High Modules: High "Young's Modulus"

1.3. Resin Matrix

The traditional FR4 board is mainly Epoxy, and the LF (Lead Free) / HF (Halogen Free) board adopts a variety of resins and different curing agents to make the cost increase, LF is about 20%, HF is about 45%.

HF plate is brittle and easy to crack, and the water absorption rate becomes large. CAF is easy to occur in thick and large plates. It is necessary to use open fiber cloth and flat fiber cloth, and strengthen the impregnated uniform material.

Good resin must have the following conditions:

Heat Resistance: Good heat resistance. After heat welding for two to three times, the board will not burst, so it is called good heat resistance.

Low Water Absorption: Low water absorption. Water absorption is the main cause of PCB explosion.

Flame Retardance: Must be flame retardant.

Peel Strength: Has a high "tear strength".

High Tg: high glass transition point. Most materials with high Tg are not easy to absorb water. Non-water absorption is the root cause of non-violent board, not because of high Tg.

Toughness: Good "toughness". The greater the toughness, the less likely it is to burst. Toughness is also called "destructive energy". The tougher a material is, the stronger its ability to withstand impact and damage.

Dielectric properties: high dielectric properties, that is, insulating materials.

1.4. Fillers System

Fillers should be coupled first to improve dispersion and adhesion.

Drill processibility: Because of the high rigidity and toughness of the powder, it makes PCB drilling difficult.

High Modulus: Young's Modulus

Heat Dissipation (due to high thermal conductivity): For heat dissipation.

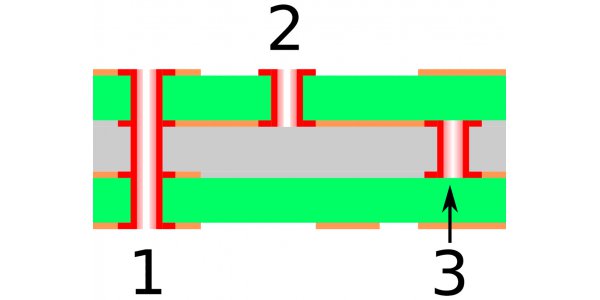

2. PCB substrate is the key to the stability of the delay line

In PCB circuits, the delay line is a very useful structural element for adjusting signals in analog and digital circuits. The main characteristics of high-frequency and high-speed delay lines include operating bandwidth, delay time, insertion loss within the operating bandwidth, return loss, standing wave ratio, rise time, and delay stability. The delay line can be realized by different circuit components, such as coaxial lines, bulk acoustic wave components, surface acoustic wave components, etc. However, the choice of PCB material will have a significant impact on the final performance of the delay line. The consistency of the constants of the entire PCB and the consistency of the thickness of the PCB will greatly affect the performance uniformity and expected effect of the delay line. Quite simply, no matter for stripline or microstrip line circuits, the better the consistency of the dielectric constant Dk in the PCB, the better the consistency of the material thickness, the better the stability of the delay line in the PCB.The role of the delay line in the circuit is mainly to serve as an electromagnetic signal transmission medium. When the transmission medium is air, the propagation speed of the electromagnetic signal is equal to the speed of light of 300,000 km / s. Considering the PCB size that designers typically use, the speed of light can be calculated using 11.8 inches / nanoseconds or 300mm / nanoseconds. When electromagnetic signals propagate through other media, such as PCBs, the propagation rate of the signals becomes slower due to the effects of material properties such as the dielectric constant of the PCB. The dielectric constant of all circuit materials is greater than 1, and when electromagnetic waves propagate in circuit materials, a higher dielectric constant means a larger charge capacity and a lower propagation rate.

For signal lines on a PCB, the propagation rate of the electromagnetic signal is equal to the speed of light divided by the square root of the dielectric constant. Both the vacuum and air dielectric constants Dk are considered to be one. Therefore, when air is used as the propagation medium, the propagation rate of the electromagnetic signal does not change. For an FR-4 material with a dielectric constant of 4, when the electromagnetic signal propagates through it, the propagation rate is equal to the speed of light divided by the square root of the dielectric constant, that is, divided by 2. Therefore, the speed of signal propagation in FR-4 material is half that of air or vacuum.

For RF microstrip delay lines, the electromagnetic field passes through the metal conductor and the dielectric material combination, including the PCB dielectric material below the circuit conductor and the air above the circuit. For radio frequency band delay lines, the electromagnetic field passes through the air above the circuit and the PCB dielectric material below, especially for multilayer board circuits that use vias to connect different circuit layers. Coplanar waveguides are also commonly used in RF microwave delay lines. Differences in PCB material characteristics such as dielectric material thickness and copper wire thickness tolerances will have a significant impact on the performance of the delay line.

Of course, for a specific PCB material, the processing technology and assembly technology of the circuit are closely related to the consistency of the performance of the delay line. Ideally, even if the deviation of the thickness and dielectric constant of the PCB material is very small and the consistency is very good, the difference in the characteristics of different PCB materials will be translated into the performance difference of the delay line. Undesirable capacitive effects caused by factors such as circuit junctions should be minimized, as an increase in capacitance will result in an increase in delay time. In order to ensure good electrical performance stability, the PCB delay line must be designed with a large ground plane.

In the actual design of a delay line circuit, finding the right PCB material must weigh multiple factors. From the standpoint of excellent performance, Rogers' RT 5880 circuit material is a PTFE-based material that is cured by glass microfiber. RT 5880 circuit material has a polar dielectric constant and a small tolerance, Dk is 2.2, and the tolerance is 0.02. At the same time, its loss factor is also small, with a variety of laminate sizes and thicknesses (up to 0.005 inches). When using RT 5880 to design the delay line, the thickness can be strictly controlled to reduce the effect on the delay line. Of course, good performance often means higher costs. PCB materials with low Dk values and ultra-low Dk tolerance are somewhat more expensive than other materials. These materials are often used in the most challenging circuit equipment, such as military electronics.

Taking the properties and cost of the material into consideration, RO3003 material of Rogers is also based on PTFE and is ceramic reinforced. RO3003 has a dielectric constant of 3.00 and a tolerance of 0.04. Its loss factor is also small and it is easy to accurately control the thickness to reduce the impact on the performance of the delay line. Rogers is a cost-effective PCB material for laminates and delay lines. At 10GHz, the RO4835 has a Z-axis dielectric constant of 3.48 and a tolerance of 0.05. In addition to being compatible with the lead-free process, the thickness deviation of this material is also very small, which can be processed using the FR-4 material standard process to reduce product costs. In order to meet different design requirements, the material has a wide range of applicable thicknesses and copper foil thicknesses, with the thinnest thickness being 0.0066 inches.

In order to achieve the design goals of the delay line, in addition to the choice of PCB materials, many factors need to be considered. Each interface of the RF microwave circuit may cause the delay time of the delay line to increase. For PCB circuits that use coaxial connectors for signal transmission, the interface between the circuit board and the connector introduces changes in the delay time. These interfaces or signal transition points should be as consistent at both ends as possible to reduce variations in circuit delay time. RO4835 laminate materials can provide extremely small Dk tolerances, precise thickness control, and low loss performance levels to meet the consistency requirements of delay line performance.