Posted: May 14, 2022 by: Bonnie

Wave soldering and reflow soldering are two common electronic product soldering methods in the production process of electronic products. The main differences between them are: wave soldering is used for soldering plug-in circuit boards, and reflow soldering is used for soldering SMT chip circuit boards. Next, Guang Shengde will come and talk about the difference between wave soldering and reflow soldering in detail.

To SMT products have the advantages of compact structure, small size, vibration resistance, impact resistance, good high-frequency characteristics, and high production efficiency. SMT has occupied a position in the circuit board assembly process.

The typical surface mount process is divided into three steps: applying solder paste-mounting components-reflow soldering

Step 1: Apply solder paste

The purpose is to evenly apply an appropriate amount of solder paste on the PCB pads to ensure that the SMD components and the corresponding pads of the PCB achieve a good electrical connection and have sufficient mechanical strength during reflow soldering.

Solder paste is a paste with fixed viscosity and good touch characteristics that is mixed with an alloy powder, paste flux, and some additives. At room temperature, due to the fixed viscosity of the solder paste, electronic components can be pasted on the PCB pads. Generally, the components will not move when the inclination angle is not too large and there is no external force collision. When the paste is heated to a constant temperature, the alloy powder in the solder paste melts and then flows, and the liquid solder infiltrates the solder ends of the components and the PCB pads. After cooling, the solder ends and the pads of the components are interconnected by the solder, forming electrical and mechanical Connected solder joints.

The solder paste is applied to the pad by special equipment, the equipment includes GSD automatic printing machine, GSD semi-automatic printing machine, manual printing station, semi-automatic solder paste dispenser, GSD solder paste mixer auxiliary equipment, etc.

Usage Advantages and DisadvantagesMachine printing: GSD semi-automatic solder paste printing machine has a large batch size or high precision, high flexibility, tight delivery cycle, mass production, and production efficiency. High investment cost!

Manual printing Small batch production, low-precision product research, and development, low-cost Simple positioning, unable to carry out mass production, only suitable for printing of components with a pad spacing of 0.5mm or more Manual drop coating R&D of ordinary circuit boards, repairing pad solder paste Auxiliary equipment is required for R&D and production Only applicable to the drip coating of components with a pad spacing of 0.6mm or more.

Step 2: Place the components

This process is to accurately mount the chip components to the corresponding position on the PCB surface where the solder paste or patch glue is printed with a placement machine or manually. There are two mounting methods, the comparison is as follows:

First: The advantages and disadvantages of the use of the placement machine: machine printing, large batches, tight delivery cycles, sufficient funds, mass production, high production efficiency, complex use procedures, and large investment!

Second: manual printing, small and medium batch production, product development, easy operation, low cost, and production efficiency must be based on the proficiency of the operator. The main tools for manual manual placement: vacuum suction pen, tweezers, IC suction and aligner , Low-power stereo microscope or magnifying glass, etc.

The third step: reflow soldering

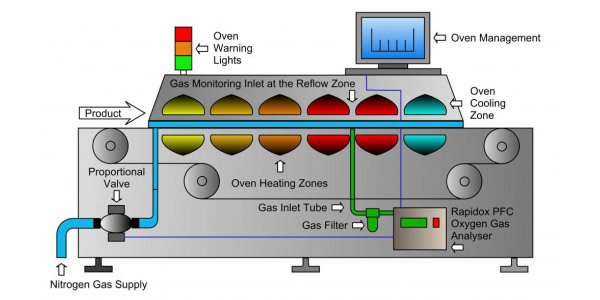

When the PCB enters the preheating temperature zone of 140℃~160℃, the solvent and gas in the solder paste evaporate. At the same time, the flux in the solder paste wets the pads, component solder ends, and pins and the solder paste softens and collapses. It covers the pads, isolates the pads and component pins from oxygen; and allows the surface mount components to be fully preheated, and then enters the soldering area, the temperature rises rapidly at a standard heating rate of 2-3°C per second The solder paste reaches a molten state, and the liquid solder wets diffuses, diffuses, flows, and reflows on the PCB's pads, component solder ends and pins to generate metal compounds on the soldering interface to form solder joints; then the PCB enters the cooling zone for soldering Point freeze.

Introduction of reflow soldering method: different reflow soldering has different advantages, and the process flow is of course different.

Infrared reflow soldering: high thermal efficiency by radiation conduction, large temperature steepness, easy to control temperature curve, easy to control the upper and lower temperature of PCB during double-sided soldering. There is a shadow effect, the temperature is uneven, and it is easy to cause partial burnout of components or PCB

Hot air reflow soldering: convection conduction uniform temperature, good soldering quality. The temperature gradient is not easy to control

Forced hot-air reflow soldering: Infrared hot-air mixed heating combines the advantages of infrared and hot-air furnaces, and can obtain excellent soldering effects when products are soldered. Forced hot-air reflow soldering can be divided into two types according to its production capacity:

1. Temperature zone equipment: mass production is suitable for mass production. PCB boards are placed on the conveyor belt. They must pass through a number of fixed temperature zones in sequence. If the temperature zone is too small, there will be a temperature jump phenomenon, which is not suitable for high-density assembly board welding. Moreover, it is bulky and consumes high power.

2. Temperature zone small desktop equipment: small and medium batch production is quickly developed in a fixed space, the temperature changes with time according to the set conditions, and the operation is simple. Defect surface mount components (especially large components) can be repaired, not suitable for mass production.

Because the reflow soldering process has the characteristics of "reflow" and "self-positioning effect", the reflow soldering process has relatively loose requirements for placement accuracy, and it is easier to achieve a high degree of automation and high speed of soldering. At the same time, because of the characteristics of reflow and self-positioning effects, the reflow soldering process has more stringent requirements for pad design, component standardization, component tip and printed board quality, solder quality, and process parameter settings.

Cleaning is the process of removing pollutants and impurities on the surface of the object to be cleaned by physical action and chemical reaction. Whether it is solvent cleaning or water cleaning, it must go through surface wetting, dissolution, emulsification, saponification, etc., and apply different methods of mechanical force to peel off the dirt from the surface of the surface assembly board, and then rinse or rinse it. After drying, drying, or natural drying.

Reflow soldering is a key process in SMT production, and a reasonable temperature profile setting is the key to ensuring the quality of reflow soldering. Inappropriate temperature curves will cause soldering defects such as incomplete soldering, false soldering, component uplifting, and excessive solder balls on the PCB, which will affect product quality.

SMT is a comprehensive system engineering technology, and its scope includes substrates, design, equipment, components, assembly processes, production accessories, and management. SMT equipment and SMT process require stable voltage at the operating site, prevent electromagnetic interference, prevent static electricity, have good lighting and exhaust emission facilities, and have special requirements for the temperature, humidity, and air cleanliness of the operating environment. Operation The personnel should also undergo professional technical training.

Introduction to wave soldering method

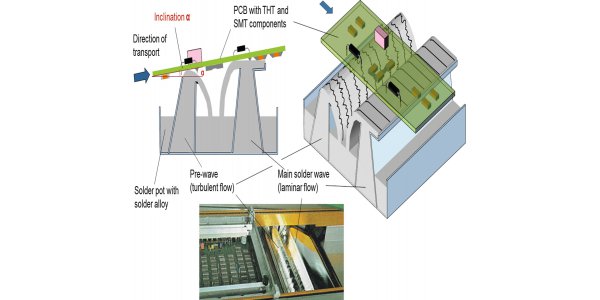

Wave soldering refers to the molten solder (lead-tin alloy) sprayed into the solder wave required by the design through an electric pump or an electromagnetic pump. It can also be formed by injecting nitrogen into the solder pool to make the pre-installed components The printed board realizes the soft soldering of the mechanical and electrical connection between the solder end of the component or the pin and the printed board pad through the solder wave. According to the wave of different geometric shapes used by the machine, the wave soldering system can be divided into many kinds.

Wave soldering process: insert the component into the corresponding component hole → pre-applied flux → pre-baking (temperature 90-1000C, length 1-1.2m) → wave soldering (220-2400C) → cut off excess plug-in feet → check.

The difference between wave soldering and reflow soldering:

The reflow soldering process is to remelt the paste-like solder pre-distributed on the printed board pad to realize the mechanical and electrical connection between the solder end of the surface mount component or the pin and the printed board pad.

With the enhancement of people's awareness of environmental protection, wave soldering has a new welding process. In the past, tin-lead alloy was used, but lead is a heavy metal that can cause great harm to the human body. So now there is the production of lead technology. It uses *tin-silver-copper alloy* and special fluxes, and the soldering temperature requires higher and higher preheating temperature. It is also necessary to set up a cooling zone workstation after the PCB board passes through the soldering zone. This is for On the other hand, if there is ICT, it will affect the detection.

Wave soldering can basically be solved as follows. It is different from reflow soldering for soldering slightly larger and smaller components. However, reflow soldering heats the board and components, which is actually to liquefy the solder paste that was originally brushed on. , In order to achieve the purpose of connecting the component and the board.

1)Reflow soldering passes through the preheating zone, reflowing zone, and cooling zone. In addition, wave soldering is suitable for manual boards and dispensing boards, and all components are required to be heat-resistant. The surface of the wave must not have components that used to be SMT solder paste. SMT solder paste boards can only be reflow soldered, not Use wave soldering.

2) Wave soldering is to melt the tin bar into a liquid through the tin bath and use the motor to stir to form a wave so that the PCB and the parts can be welded together. It is generally used for the soldering of the hand plug-in and the SMT glue board. Reflow soldering is mainly used in the SMT industry. It uses hot air or other heat radiation to melt the solder paste printed on the PCB and solder the parts.

3)The process is different: wave soldering must first spray flux and then go through preheating, soldering, and cooling zone.

The second difference between wave soldering and reflow soldering: Wave soldering is mainly used for soldering plug-ins; reflow soldering is mainly used for patch-type components

1) Wave soldering is to melt the tin bar into a liquid through a tin bath and use the motor to agitate to form a wave so that the PCB and the parts are welded together. It is generally used for the soldering of hand plug-ins and the glue board of SMT. Reflow soldering is mainly used in the SMT industry. It uses hot air or other heat radiation to melt the solder paste printed on the PCB and solder the parts.

2)The process is different: wave soldering must first spray flux, and then go through preheating, soldering, and cooling zone. The reflow soldering passes through the preheating zone, reflowing zone, and cooling zone. In addition, wave soldering is suitable for manual boards and dispensing boards, and all components are required to be heat-resistant. The surface of the wave must not have components that used to be SMT solder paste. SMT solder paste boards can only be reflow soldered. Wave soldering.