How to calculate copper thickness on PCB? It might sound simple. However, although we can see copper thickness requirements noted in customer drawings or specifications, this requirement may lead to additional engineering questions (EQ) and in some cases additional costs. These are unintentional consequences of misunderstanding the requirements, of course not in all cases, but in some cases. Let's look at some terminology first.

An ounce(OZ) is the weight of copper spread over a square foot area. The area of the circuit board itself does not change and is fixed. But as the copper weight increases, the thickness of the copper deposit will increases accordingly. So what exactly does ½ oz, 1 oz, or 2 oz mean? It is generally accepted that ½ oz equals 17 microns (0.669 mils), 1 oz equals 35 microns (1.377 mils), and 2 oz equals 70 microns (2.756 mils). While the numbers are close, it's not strictly speaking.

This leads to the IPC standards, specifically IPC-6012 - Qualification and Performance Standard for Rigid PCB.

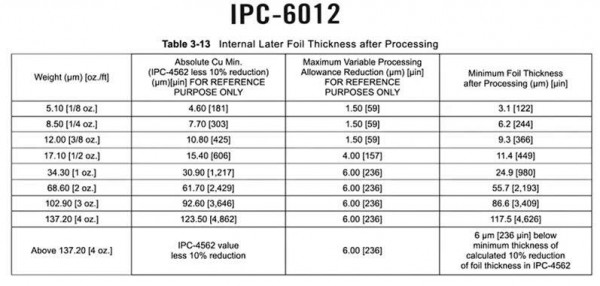

First look at the thickness of the inner foil as below picture.

We can see that 1oz is actually equal to 34.3 microns (1.350 mils), which is the goal of copper foil manufacturers. However, a 10% tolerance is allowed for the resulting copper foil, which means that a 1 oz inner layer foil received by a PCB factory maybe 30.9 microns (1.217 mils) thick. Therefore, we will also see that the copper foil pretreatment reduces the thickness by 6 microns (0.236 mils) before imaging and bonding in the PCB factory. After pre-processing, the minimum copper foil thickness for 1 oz copper foil maybe 24.9 microns (0.980 mils), which is a bit different from what we think is 35 microns.

We see a potential challenge when we see that the thickness of the inner layer is specified as a minimum of 35 microns. This means that to reach 35 microns (1.377 mils) of copper foil thickness after processing, it needs to start at 2oz. 2oz of copper foil that can reach a thickness of 55.7 microns (2.193 mils).

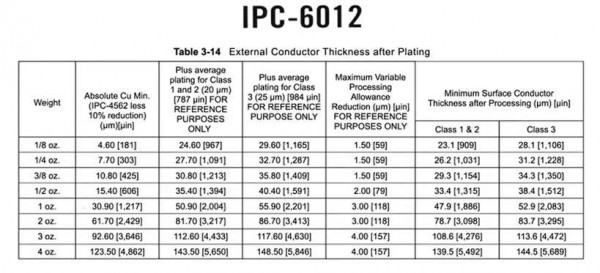

Now let's look at the more complex outer layer as below picture. As an industry-standard, IPC-6012 specifies the base copper weight, not the finished copper weight.

IPC Table 3-14 shows that the minimum surface conductive layer for copper formation is equal to the absolute minimum copper foil thickness. For IPC Class2 products, add an average copper plating thickness of 20 microns (0.787 mils). For IPC Class 3 products, add an average copper plating thickness of 25 microns (0.984 mils), minus the maximum allowable reduction in processing. Let's see what happens when a customer asks for 1 oz of finished copper.

We know that for 1oz copper weight, the IPC specifies a minimum value equal to 30.9 microns (1.217 mils). If we start with ½ oz / 15.4 microns (0.606 mils), add 20 microns (0.787 mils) plating for IPC Class 2 standard or 25 microns (0.984 mils) plating for IPC Class 3 standard. Then adding a machining tolerance of 2 microns (0.079 mils), it can be seen that thicknesses of 33.4 microns (1.315 mils) can be achieved for IPC Class 2 standard and 38.4 microns (1.512 mils) for IPC Class 3 standard.

The instructions are very clear and very close to 1oz (35 microns) thickness. But as the copper weight increases, the situation is different. Let's look at the 2 oz (70 microns) requirement, and based on what we thought was an initial value of 35 microns, add an additional 35 microns or 1 oz of base plating, it felt like it would meet the requirements. If we take 1 oz or 30.9 microns (1.217 mils) of copper foil, add 20 microns (0.787 mils) for grade 2, or 25 microns (0.984 mils) for grade 3, then machining tolerances are allowed A reduction of 3 microns (0.118 mils). The resulting copper thickness will then be 47.9 microns (1.886 mils) for IPC Class 2 standard and 52.9 microns (2.083 mils) for IPC Class 3 standard.

When drawings call for a specified thickness of copper foil or a minimum thickness of 70 microns (2.756 mils), we must start with 2 ounces of base copper foil and after the plating according to the IPC Class 2 standard, the finished copper thickness is 78.7 microns (3.098 mils). Or after the plating according to the IPC Class 2 standard, the finished copper thickness is 83.7 microns (3.295 mils).

This has a significant impact on costs, as the price quoted on a 1oz basis is very different from a quote on a 2oz basis. This is why you may receive engineering questions from your PCB supplier because we want to clarify what copper thickness you need, and what base copper thickness we should start with. We always want to help you avoid any unnecessary extra costs in your PCB design.

Feel free to contact AiPCBA if you have any questions about this or anything related to PCB design, We'd be more than happy to help.

AiPCBA specializes in the following businesses: flexible PCB, custom PCB, prototype PCB, turnkey PCB assembly, quick turn PCB assembly, electronic PCB assembly, small batch PCB assembly, etc. Learn more about AiPCBA PCB Manufacturing Capabilities.

All PCBs in AiPCBA are produced based on UL and ISO certification standards. All our normal specification PCBs are strictly obeying to IPC-A-6011/6012 Class 2 latest version and IPC-A-600 Class 2 latest version.

AiPCBA online intelligent manufacturing service provides quick PCB prototype and volume production services for 1 million small and medium-sized customers around the world. The entire process of customer online ordering, evaluation, production process monitoring, and delivery is completed online in the cloud.

Starting to Quote with AiPCBA now!