What is PCB?

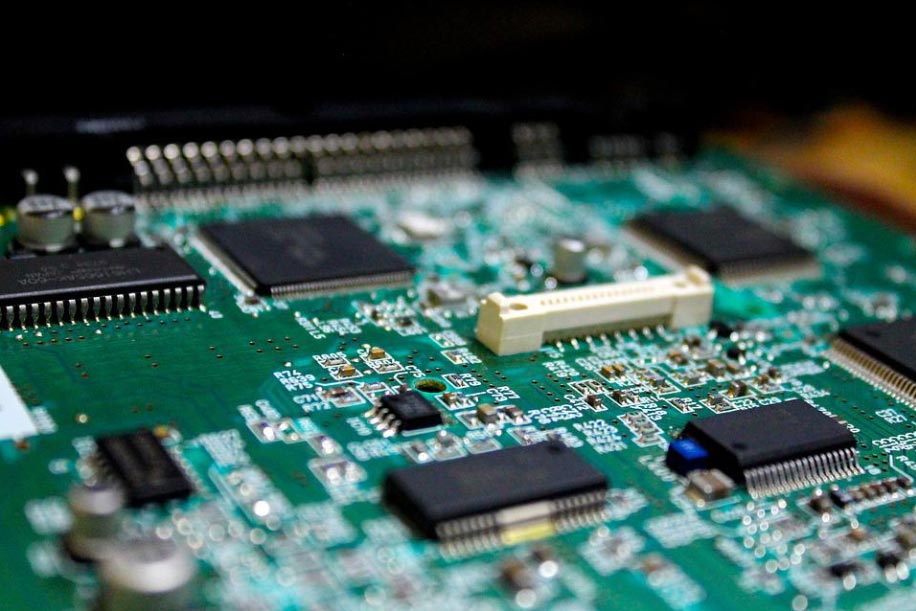

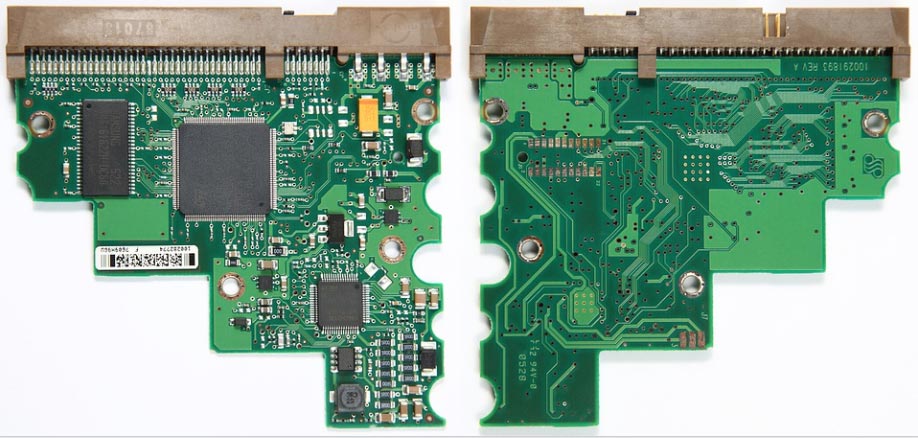

Printed circuit board (PCB) is an important electronic part, support for electronic components, and a carrier for the electrical connection of electronic components. Because it is made using electronic printing, it is called a "printed" circuit board. According to the complexity of electronic products, PCBs can be divided into single-sided PCBs to multi-layer PCBs. It can be classified as a simple through-hole or a blind & buried hole.What is PCBA?

Printed Circuit Board Assembly (PCBA) refers to refers to the entire process of assembling components onto bare printed circuit boards through SMT or DIP. It is a production and processing step, and it can also be understood as a finished PCB product, which means it can be called PCBA after the assembly process on the PCB board is completed.What is SMT?

Surface Mount Technology (SMT) is the most popular technology and process in the electronic assembly industry. It is a PCB assembly technology that mounts leadless or short lead surface mount components (SMC/SMD) on the surface of the printed circuit board, and then solders and assembles them by reflow soldering or DIP soldering.What is BOM?

Bill of materials (BOM) is called product structure table or material structure table, which records in detail all the materials and related attributes used in the project. In the PCBA, the content of the general BOM list includes the part number, specification, description, footprint, and quantity of the components.AiPCBA provide PCB manufacturing and assembly service. We have customers from different industries in terms of cost-effectiveness, quality, delivery and any other requirements. From PCB layout to PCB prototyping, volume production, and then PCB assembly, electronic box assembly services, our printed circuit boards are widely used in robotics, medical, automotive, communications, industrial and consumer electronics products.

Difference between PCB and PCBA

PCB and PCBA are interrelated in electronics, and there is no PCBA without PCB.(1)A PCB is a board made of non-insulating and highly heat-resistant insulating materials such as fiberglass. These boards are also called substrates. Conductive metals like copper (and sometimes gold) are used to make conductive circuits or vias or traces so that current flows in a predetermined, controlled manner. Once a PCB is produced and the circuit on the board is ready, it is called a PCB or Printed Circuit Board without the electronic components assembled or soldered on it. These boards can be single-layer, double-layer or multi-layer according to the requirements of the electronic product.

(2)Once the PCB is ready, it must be assembled with active and passive electronic components such as resistors, SMD capacitors, transistors, transformers, diodes, ICs, etc. These electronic components can be through-hole components or SMD components for smt processing (surface mount technology).

(4)A PCB is a circuit board without electronic components. Once all the necessary electronic components are assembled or soldered to the PCB, it is called PCBA.

In AiPCBA, we offer PCB Manufacturing. Not only we can produce single PCB and multilayer PCB but also we can produce PCB with complicated technology such as HDI PCB, Rigid+Flex PCB, metal PCB.

AiPCBA has led the PCB industry for over 7 years, offering the industry's most advanced printed circuit board technology and the highest quality standards. You can customize your PCB at AiPCBA. From the simplest printed circuit boards to the most complex low-volume and large-scale production, AiPCBA has the capability to meet all your contract electronics manufacturing needs.

Difference between PCBA and SMT

(1)SMT is a surface mount technology, which is to mount electronic components on a PCB through a technical process. Because the electronic components mounted by SMT are chip components without leads, it is also called SMT assembly. The SMT assembly process is roughly divided into: solder paste printing, component placement, reflow soldering, and testing. The components are mounted on the PCB through the SMT equipment, and then reflow soldering is performed, and the solder paste is melted to connect the components and the PCB pads, and the soldering is formed after cooling. Finally, the whole SMT production process is completed after being tested by AOI and other testing equipment.

To the PCB Assembly, whether your technology includes Surface Mount (SMT), Through-hole, or a mixed technology for single or double-sided boards in small quantities, prototypes, or large production runs, AiPCBA has the ability to provide for all of your contract electronics manufacturing needs. Learn more about AiPCBA’s PCB Assembly service

Online PCB Assembly Quote: Based on AiPCBA's PCB and BOM online quote system, we have also developed the calculation formula for assembly costs accordingly and combined these three quotation systems to form our complete one-stop PCBA quotation. As long as you upload the Gerber file and BOM list, our system will give you a complete PCBA quotation within 30 seconds.

The importance of BOM in PCBA

(1)The BOM list is the final specific materials and components required for the PCBA product. The factory will purchase according to the BOM list provided by the customer. Finally, the components are assembled and welded on the PCB, and the products that pass the test will be sent to the customer.

(2)The entire PCBA production process is driven by the BOM list. Because the function of the PCB depends on the components in the BOM list. Of course, in addition to components, PCB layout is also very important.

AiPCBA has an experienced component expert service team and a senior material supply chain team, providing professional replacement services for risky materials to help you reduce material costs and supply chain risks. The material cost of PCBA products can be reduced by more than 50%.

AiPCBA also connects with global distributors Digikey, Mouser, Arrow, RS, etc., as well as the API interface of spot inventory data of more than 800 domestic spot suppliers in China, to grasp the advantageous channels of material supply and inventory changes in real-time. Self-developed ERP system provides strong support for the supply chain management.

Online BOM quote: AiPCBA's self-developed BOM quotation system can identify component information within 30 seconds, and analyze and quote market prices. And our BOM quotation system does not have strict requirements on the BOM format, all of which are based on the development of our strong R&D team, and play an extremely important role in our thousands of BOM price confirmations.