Electroless copper plating, also known as through-hole plating (PTH), is an auto catalytic redox reaction. PTH process is carried out after drilling two or more layers. The function of PTH is to deposit a thin layer of chemical copper on the non-conductive cell wall substrate of drilling hole as the substrate for subsequent copper plating. PTH process decomposition: alkaline degreasing → 2 or 3 times counter current washing → roughening (micro etching) → secondary counter current washing → pre-dip → activation → secondary counter current washing → debonding → secondary counter current washing → sinking → secondary counter current washing → pickling.

PTH detailed process description:

1) Alkaline degreasing

Remove the oil, fingerprint, oxide and dust in the hole on the surface of the plate, and charge the hole wall from negative to positive charge to promote the adsorption of colloidal palladium in the subsequent process. After degreasing, it should be cleaned in strict accordance with the guidelines and tested with a copper back light test.

2) Micro etching

Remove the oxide on the surface of the circuit board and make the surface rough to ensure the good adhesion between the subsequent copper layer and the bottom copper of the substrate. The new copper surface has strong activity and can adsorb colloidal palladium well.

3) Pre-impregnation

It mainly protects the palladium tank from the pollution of the pre-treatment tank and prolongs the service life of the palladium tank. In addition to palladium chloride, the main component is the same as that of palladium pot. Palladium chloride can effectively wet the pore wall, promote the activation solution to activate the pore later, which can effectively activate.

4) Activation

After adjusting the polarity of alkaline degreasing, the positive hole wall can effectively adsorb colloidal palladium particles with negative charge, and ensure the average, continuous and dense sinking of subsequent copper; activation is very important for the quality of subsequent copper bath. It is very important to control the concentration and the specific gravity of SN2 + and the concentration of SN2 + must be controlled strictly.

5) Peptization

The removal of stannous ions from colloidal palladium particles and exposure of palladium core in colloidal particles can directly catalyze the initiation of chemical copper precipitation reaction. Experience shows that it is better to use fluoroboric acid as debonding agent.

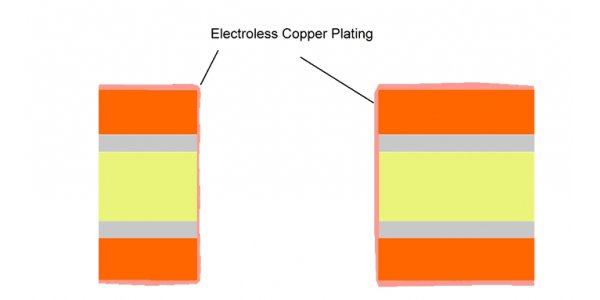

6) Electroless copper plating

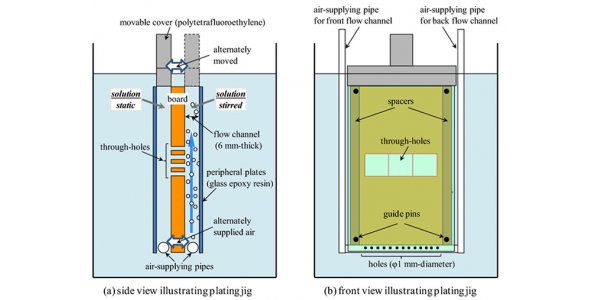

The auto catalytic reaction of electroless copper plating is caused by the activation of palladium nucleus. The new chemical copper and the reaction by-product hydrogen can be used as the reaction catalyst for the catalytic reaction, so that the copper precipitation reaction can continue. After this step, a layer of chemical copper can be deposited on the surface of the plate or the wall of the hole. In this process, bath solution should be kept under normal air stirring to convert more soluble copper.

The quality of copper plating process is directly related to the quality of PCB. It is the main source process of through hole and short circuit. Visual inspection is not convenient. Post processing can only be used for probability screening through destructive experiments. Effective analysis and monitoring of a single PCB, once there is a problem, there will be batch problems, even if the test can not be completed, the final product will also cause great quality hazards, only batch scrap, so strictly follow the parameters of the work instructions.