1. PCBA test fixture principle and manufacturing method

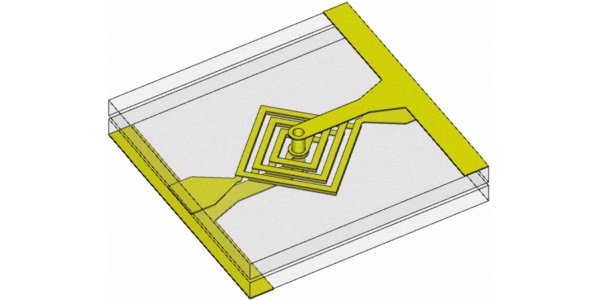

The principle of the PCBA test fixture is very simple. Connect the pad or test point on the PCB board with a metal probe. When the PCB board is powered on, obtain the typical values such as the voltage value and current value of the test circuit to observe the test. Whether the circuit is conducting normally.

The quality of the PCBA test stand is related to the efficiency and through rate of ICT testing. Due to its long-term and frequent operation, it has high requirements for its production quality.

2. How is the price of PCBA test fixture calculated?

General test fixtures are produced by outsourced professional factories, but there is no reference standard for their pricing system, and often the quotations of several manufacturers are very different. Choosing a low-cost test fixture sometimes brings huge risks in test performance and service.The cost of the test fixture includes hardware such as acrylic, plastic parts, wires, metal probes, PCB boards, and very simple software detection procedures. Among them, the cost of acrylic is very easy to measure, you can use price/kg to roughly measure its cost, and the special-shaped acrylic test fixture can be measured according to price/kg.

The cost of auxiliary plastic parts, wires and metal probes can be almost negligible. The PCB board can be calculated according to the size of the double-sided per square meter price. The cost of software and SMT chip components mainly depends on the most expensive cost, such as the price of IC and important components.

The biggest cost is labor. It takes labor hours for the production of test jigs and fixtures in the factory. Although it is now a standard lathe operation, it takes about 1-2 hours to make a relatively simple test jig (including cutting, assembly, welding, etc.) .

Through the above rough calculations, the cost of the test fixture can be obtained. The cost-plus method is used to determine the price of each PCBA test fixture jig.