Why Bill of materials is very important in PCB manufacturing process is that the importance of efficient production planning cannot be underestimated. It has a long way to go in optimizing production and balancing production lines. Therefore, hourly demand is a powerful design data, including PCB layout data, bill of materials, commonly known as BOM and product reference. More basic information can refer to what is BOM and know about the method to build up BOM.

In fact, the whole SMT manufacturing process is driven by BOM. This is because the function of the PCB depends on the components listed in the BOM. In turn, using the correct components is critical to the function of the PCB. Therefore, any PCB assembly order needs to be initiated using BOM. The BOM contains not only a list of components, but also their locations on the printed circuit board. In turn, BoM allows purchasing experts to find the right distributors for the components, as well as cost-effective price points. Some components may not be available, so it provides purchasing experts with the opportunity to find an alternative distributor to work seamlessly.

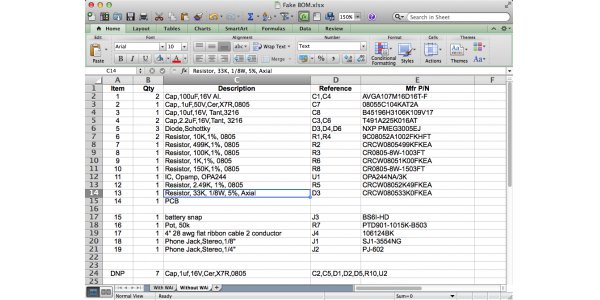

Detailed BOM, including specifications related to project number, description of components, name of manufacturer, quantity, etc., is very convenient. This not only ensures quality, but also ensures that PCB manufacturers are able to follow delivery deadlines without any hiccups. In the case of turnkey components, the names and details of distributors and manufacturers must also be mentioned. In fact, multiple dealer names can help with the procurement process and ensure that time is not wasted when a particular dealer does not have readily available parts.

The optimized component list allows well-organized planning and clear planning of scheduling steps. This in turn ensures zero error in PCB production. On the other hand, the lack of an effective BOM can mean a large number of revisions that eventually lead to a delay in delivery.The manufacturer usually provides templates for the sample BOM so that all necessary information can be captured, so there is no room for ambiguity. Support for explosions and implosions is also often included in the BOM. Although an explosion refers to a component that displays a component, implosion helps to see where a particular component is used and determine which parts are associated with any component at risk. Therefore, the layered BOM can easily study the whole structure.

When creating a BOM, you need to pay special attention to the following aspects:

1) Highly completed - ideally, BOM should help manufacturers create PCBs from scratch. If you have received a BOM template from the manufacturer, make sure you spend enough time completing and providing all the necessary details.

2) Indicate where you can allow flexibility - some parts may be critical where you want manufacturers to adhere strictly to the approved supplier list. Although other non critical factors may exist, they can be optimized for cost. It's best to make this clear in the BOM so that you don't waste time on unnecessary revisions, or worse, you may encounter procurement errors that can cost you dearly.

3) Confirm all parts are available - when listing parts in the BOM, a quick check of whether parts are available at all times will greatly help ensure seamless production. Ignoring this step often leads to expensive design decisions at a later stage.