The cleaning and maintenance methods of the circuit board are as follows:

1) Preparation before cleaning all connectors on the circuit board including jumper plugs, card boards, batteries and ICs must be carefully pulled out before cleaning. Potentiometers, transformers and solenoid coils (inductor coils) must also be pulled out. Remove from the circuit board, non-electronic professionals should not do this operation. Without electronic expertise, it is easy to damage components and circuit boards during disassembly. Fortunately, there are basically no such components on the computer-related circuit boards. Therefore, once the components enter the water, the gap or the water droplets between the turns are difficult It is difficult to be dried by the compressed air and the moisture is dried. It must be recorded one by one during disassembly to ensure that there is no error when recovering after cleaning. At the same time, check the electrolytic capacitors on the circuit board for leakage or bulging at the top. If there is, remove them and make a record so that they can be replaced with new products of equivalent value after the circuit board is cleaned. For the circuit board of the computer power supply, it should also be checked whether there is a crack live de-soldering between the pad of the printed circuit and the component feet, especially focusing on the high-power components. If crack live de-soldering is found, the welding should be repaired immediately. Repair one at a place, otherwise it is easy to miss.

2) Cleaning

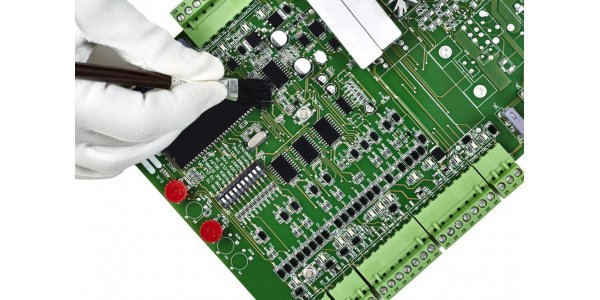

· Before cleaning, use a clean soft paint brush (1 inch wide brush is better) and dry compressed air with a pressure of about 0.1 MPA [ie 1kg/cm2] to remove the dust on the circuit board.

· For cleaning, special cleaning liquid (commonly known as board washing water) for washing circuit boards can be used. If there is no board washing water, you can operate as follows: (now we generally do not use board washing water) first rinse with tap water, pay attention to the water flow should be soft, not too fierce, carefully brush with a soft brush while flushing, both sides of the circuit board Both are true.

· Then use a soft brush with neutral soap to carefully and gently clean every place on the circuit board, especially the inside and bottom of the jumper plug, socket (CPU socket, AGP slot, PCI slot, memory slot), The bottom of the IC socket, the north-south bridge chip, the BIOS chip and each other IC chip, the bottom of the large capacitor, etc. should be carefully cleaned, and care should be taken not to knock the small capacitor and other components installed vertically; if it is found to be washed out The soap foam is very dirty, you must rinse it with clean water, and then wash it again with soap until the soap foam is white.

· After that, rinse the circuit board thoroughly with clean water. Soap water must be thoroughly washed away.

· After washing, use compressed air with a pressure of about 0.1 MPA [ie 1kg/cm2] to blow off the water droplets, especially the inside of the jumper plug and socket (CPU socket, AGP slot, PCI slot, memory slot) And the bottom, the bottom of the IC socket, the north and south bridge chips, the BIOS chip and the bottom of each other IC chip, the bottom of the large capacitor, etc., it should be purged from its different directions, and strive to blow all the water drops in the gap clean . If you do not have compressed air, you can use a rubber hand pump for watch repair or camera repair, but this can be tiring.

·Slightly wash the circuit board once again with double distilled water or absolute alcohol (with the side where the component is soldered facing upwards, slanting the circuit board, use a clean oil paint brush No. 10~12 to call it with absolute alcohol from top to bottom For cleaning). The use of carbon tetrachloride is more effective, but this thing is toxic and must be used with care. Do not use it unless it is necessary. It is generally recommended not to use carbon tetrachloride. At this point, the cleaning is over. This cleaning is not only clean and thorough, but also saves money, is environmentally friendly and healthy.

3) Blow off the water droplets with dry compressed air with a pressure of about 0.1 MPA [ie 1kg/cm2], especially the inside and bottom of the jumper plug, socket (CPU socket, AGP slot, PCI slot, memory slot), The bottom of the IC socket, the north-south bridge chip, the BIOS chip and each other IC chip, the bottom of the large capacitor, etc., should be purged from different directions, and strive to blow all the water drops in the gap clean.

4) The circuit board after cleaning must be thoroughly dried before it can be put into use

· Dry in an oven, the oven temperature is adjusted to about 80 degrees Celsius, which takes about 24 hours.

· Use an electric hair dryer (for industrial use or household use) to dry, but if it is not done properly, it may be unevenly dried, especially in those gaps.

· Placed in the air-conditioned room to allow it to dry naturally, which lasted about 36 hours or more.

·According to the record made when disassembling the components as a guide, restore the originals used one by one.

·Check whether the installation is qualified. Circuit boards of other equipment can also be cleaned and maintained according to the above method.