1.Water cleaning technology:

Water cleaning technology is the development direction of cleaning technology in the future. It takes water as cleaning medium, and adds surfactant, auxiliary agent, corrosion inhibitor, chelating agent and so on in the water to form a series of water-based cleaning agent. Can remove water - solvent (flux is water - soluble) and non - polar pollutants. Its cleaning process features are:1)good safety, no burning, no explosion, basically non-toxic;

2)the formulation of cleaning agent has a large degree of freedom, and it is easy to clean polar and non-polar pollutants, with a wide range of cleaning;

3)multiple cleaning mechanisms. Water is a polar solvent with strong polarity. In addition to the dissolution, there are saponification, emulsification, displacement, dispersion and other common effects, the use of ultrasound is much more effective than in organic solvents;

4)as a natural solvent, its price is relatively low, a wide range of sources.

The disadvantages of water cleaning are:

(1)in areas where water resources are scarce, the cleaning method is limited by local natural conditions due to the need to consume a large amount of water resources;

(2)some components cannot be cleaned with water, and metal parts are easy to rust;

(3)large surface tension makes it difficult to clean small gaps, and it is difficult to remove residual surfactants thoroughly;

(4)difficult drying and high energy consumption;

(5)the equipment cost is high, waste water treatment device is needed, and the equipment covers a large area.

2.Half water cleaning technique:

Semi-water cleaning mainly USES organic solvents and deionized water, plus a certain amount of surfactant, additives composed of the cleaning agent. This type of cleaning is between solvent cleaning and water cleaning. These cleaning agent belong to organic solvent, belong to inflammable solvent, flash point is higher, toxicity is lower, safer to use, but must be rinsing with water, then drying. Some detergents add 5%~20% water and a small amount of surfactant to reduce flammability and make rinsing easier. The characteristics of semi-water cleaning process are:1) strong cleaning ability, able to remove polar and non-polar pollutants at the same time, strong cleaning ability persistence;

2) two kinds of media with different properties are used for cleaning and rinsing. Rinsing generally adopts pure water;

3) dry after rinsing.

The disadvantage of this technology is that waste liquid and waste water treatment is a complex problem which needs to be solved thoroughly.

3.No cleaning technology:

In the welding process, use no-cleaning flux or no-cleaning solder paste, after welding directly into the next process without cleaning,Clean - free technology is one of the most widely used alternative technologies, especially mobile communication products are basically using wash - free method to replace ODS. At present, many kinds of free - cleaning flux have been developed at home and abroad, such as Beijing jingying company free - cleaning flux.

No-cleaning flux can be roughly divided into three categories:

1)rosin flux: inert rosin solder (RMA) is used for reflow welding, which can be launder free.

2)water-soluble flux: clean with water after welding.

3)low solid flux: no cleaning. The no-cleaning technology has the advantages of simplifying the technological process, saving the manufacturing cost and less pollution. In the last decade, the widespread use of no-cleaning welding technology, no-cleaning flux and no-cleaning solder paste is a major feature of the electronics industry in the late 20th century. The ultimate way to replace CFCs is to achieve no-cleaning.

4.Solvent cleaning technology:

Solvent cleaning is mainly the use of solvent solubility to remove pollutants. The use of solvent cleaning, because of its fast volatilization, strong dissolving capacity, so the equipment requirements are simple. According to the choice of cleaning agent, can be divided into flammable cleaning agent and non-flammable cleaning agent, the former mainly includes organic hydrocarbons and alcohols (such as organic hydrocarbons, alcohols, diol esters, etc.), the latter mainly includes chlorinated hydrocarbons and fluorinated hydrocarbons (such as HCFC and HFC class), etc.

Hcfc-type cleaning agent and its cleaning process features:

This is a hydrogen-containing chlorofluorocarbons, its evaporation latent heat is small, volatile, easy to decompose in the atmosphere, the role of the destruction of the ozone layer is relatively small, belongs to a kind of transitional products, the regulations in 2040 before elimination, so we do not recommend the use of this kind of cleaning agent.

There are two main problems: one is transitional. Because of the destruction of the ozone layer, only allowed to use until 2040; Second, the price is relatively high, the cleaning ability is weak, increased the cleaning cost.

What is the PCB cleaned with:

1). Clean PCB with washing water:

Washing board water is also the short name of the circuit board cleaning agent, is used to clean the PCB after welding the surface of the residual flux and rosin used in the chemical industry cleaning agent potions.

2). Washing water with hydrocarbon solvent:

With the widespread use of hydrocarbon cleaning agent, hydrocarbon solvent is also used in PCB cleaning; There are fast drying type and slow drying type; Quick drying cleaning effect is generally better, hydrocarbon solvent washing board water has environmental protection, non-toxic, small odor, can be distilled recycling use, it is mostly used for high-end precision PCB cleaning, such as hydrocarbon solvent washing board water frb-143.

3). Water-based washing water:

Because the water-based cleaning agent has the characteristics of environmental protection, safety, non-toxic, non-irritant gas volatilization, the author found that recently the market also gave the water-based washing board water, but because the circuit board has metal element pin, if the water-based washing board water does not have the function of rust prevention should be used with caution, because the water-based cleaning agent is easy to accelerate the corrosion and rust of the pin.

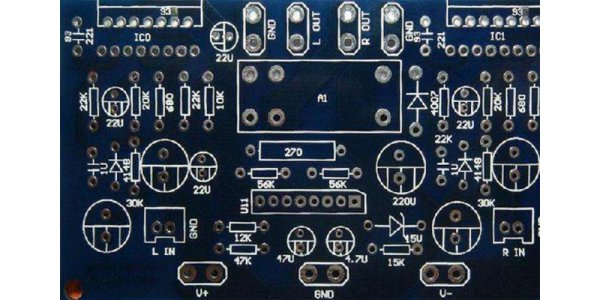

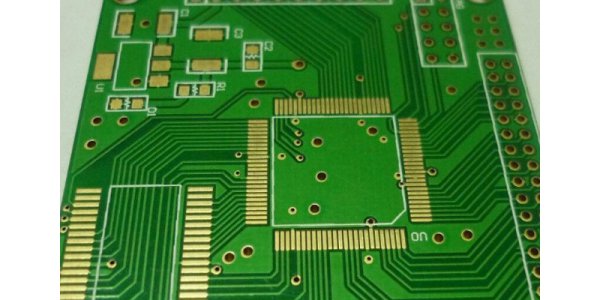

PCB is introduced:

1).PCB name: ceramic PCB, alumina ceramic PCB, aluminum nitride ceramic PCB, circuit board, PCB board, aluminum substrate, high-frequency board, thick copper board, impedance board, PCB, ultra-thin PCB, ultra-thin PCB, printing (copper etching technology) PCB, etc.

2).PCB makes the circuit miniaturized and intuitive, which plays an important role in the mass production of fixed circuit and the optimization of the layout of used electrical appliances. Printed Circuit Board (PCB), Flexible Printed Circuit Board (FPC) Flexible PCB is a highly reliable and excellent Flexible Printed PCB made of polyimide or polyester film.

3).With high wiring density, light weight, thin thickness, good bending characteristics. Reechas, Soft and hard combination plate - the birth and development of FPC and PCB give birth to the new product of reechas, Soft and hard combination plate. Therefore, the combination of hard and soft board, is the flexible PCB and hard PCB, after pressing and bonding processes, according to the relevant process requirements combined together, the formation of FPC characteristics and PCB characteristics of the circuit board.