Factors that lead to price changes include circuit board size, component type, number of components, welding method, inspection method, etc.

1). The price varies due to the number of components and their types.

The cost will depend on the type of component and technology the consumer chooses. Other factors that may affect cost include through hole components, surface mount components, fine spacing, lead-free or BGA components.

2). Double-sided assembly resulted in a significant increase in cost due to the repetition of the entire process of placing components on both sides of the circuit board. This process involves additional welding template manufacturing, SMT machine programming, etc., which may result in an increase in the average assembly price.

3). Prices may vary due to the lead-free process, but you can get full cost details from our management.

4).PCB assembly price varies according to the type and size of parts selected by consumers.

5). The cost may vary due to the type of lead-free parts, i.e. BGA, QFN, etc. Even if the cost changes due to package size (such as 02010,1206, etc.) and detection technology.

RCB research and development costs:

Research and development costs Including r & d costs and product costs, research and development costs include development costs, testing costs and labor costs, etc., product costs include procurement and material costs, manufacturing costs, etc.

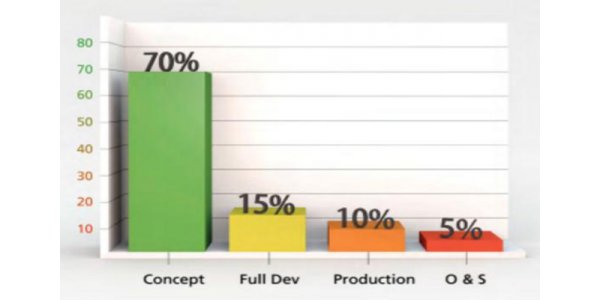

As we know, the life cycle of a product includes three stages: growth, maturity and decline. And product development and design is the source of our subsequent manufacture, sales and service, about the cost of a product is in after the success of the design has been the basic forming, as product manufacturing process, such as of late (actual manufacturing cost), its largest controllable degree can be to reduce the loss in the process of production and improve the efficiency of assembly processing (lower manufacturing costs). As shown in the following figure, the conceptual selection and decision (Concept part) in the initial stage of the design, which accounts for about 70% of the total product cost, has been determined in the design stage of the product. That is to say, once a product is developed, its subsequent material cost and labor cost have been basically qualitative, and it is difficult for the manufacturing center to change the congenital deficiencies left by the design. Many products at the design stage are destined to have higher manufacturing costs than market prices in the future.

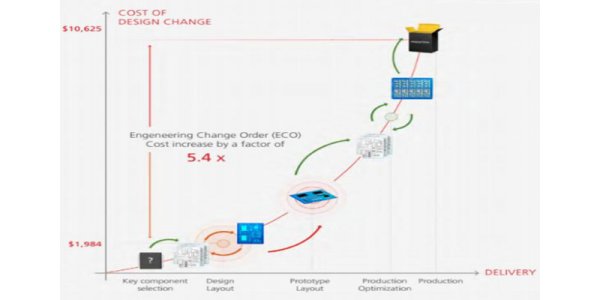

The following figure is the cost diagram of each important node in the entire life cycle of the product. It is clear from the diagram that changes made at each time node have a significant impact on subsequent phases of the lifecycle chain. And the earlier the change, the greater the impact. Shown below, for example, the design phase of a specific components change, will lead to the cost of the stages of subsequent unpredictable waste, such as product PCB layout, prototyping, product optimization and increase changes brought by the special process, relevant training, the increase of the additional cost, to the final product delivery, because of the implicit cost caused by design change waste will be several times as much.

How to effectively save the cost of raw materials:

1).To save the cost of raw materials, it naturally requires the engineering design team to cooperate with the procurement leader, share information, communicate in real time, and clearly master the price of required components, the difficulty of procurement, and the procurement cycle... Based on this information, the selection of core components was carried out, and the BOM list of the minimum system was analyzed to compare and select the most economical and applicable scheme under the premise of satisfying the function. In addition, it is necessary to effectively avoid the waste of components and inventory caused by procurement errors.

2).the supplier link function of Altium can link the supplier database information of required components directly from the designer's work interface. At any time, the engineer can check whether the packaging of the components is the packaging form required by the design, and then check the manufacturers of the components that meet the requirements of packaging, the detailed description of the components, the supply channels of the components, the unit and batch prices of the components, the inventory quantity, and so on. As shown in the following figure. With the function of link component information of suppliers, engineers can understand the purchase information of components in real time, and will compare the cost performance when selecting the model, instead of blindly choosing expensive new components or difficult components. The design engineer and the purchasing manager can communicate with each other without barriers, so that the waste of raw material cost can be avoided at the beginning of the design.

3).Another feature that can effectively save the cost of raw materials is the BOM analysis function. BOM analysis is more systematic and comprehensive than component supplier link function. The former is for the supplier purchase information of a single component, while the latter BOM analysis is for the analysis of all raw materials needed for the whole product. As shown in the following figure. For all components in the whole circuit, there are detailed component description, target price, actual price, manufacturer, manufacturer, Part No., channel supplier, supplier Part No., inventory, purchase and supply risk on the BOM list. Etc. This information can be clearly present in sight. Product managers and r&d personnel can control the cost of raw materials from a global perspective. Through the BOM list cost comparison, the need to choose the plan is also clear. More can avoid the waste caused by the procurement error of components.The supplier link function and BOM analysis function can effectively control the cost of raw materials needed for the whole product.

How to save manpower cost:

1).There are always some functional modules in the same series of products designed by the design team that are commonly needed and reused. For example, the design of the power supply part is the same in each product of the series. For this generic design fragment, after the first design test is passed, the part can be designed into a module, which is as simple and clear as an electronic component, and the reserved interface is as convenient as the component pin to be invoked in other designs. The Device Sheet feature in the Altium Designer software is a solution to this problem. It is convenient for designers to call successful design results that have been tested by others, saving time and effort, and making no mistakes. Effectively avoid duplicate designs.

2).The use of assembly variables is a replacement between the same series of different products. Different products of the same series usually have the same basic structure. When only a few devices need to be replaced, we don't even need to start a design project again, we just need to add assembly variables on the original design and calibrate the values of installed devices of different product versions. So for simple small changes, such as which devices are installed or not installed, which devices are equipped with other replacement devices in the same package, and which devices are equipped with chips with the same number of pins in the same package, all these local changes can be easily configured and managed using Variant.