Reflow soldering is to realize the soft soldering of mechanical and electrical connection between the solder end or pin of surface assembly components and the solder pad of printed board by remelting the paste soldered soft solder which is pre-distributed on the solder pad of printed board. Reflow soldering is to weld components to PCB board, reflow soldering is to the surface of the device. Reflow welding depends on the action of hot gas flow to the solder joint, the colloidal flux in a certain high temperature airflow physical reaction to achieve SMD welding; The reason why it is called "reflow welding" is that the gas circulates through the machine to produce high temperature for welding purposes.

1). When the PCB enters the heating zone, the solvent and gas in the solder paste will evaporate. At the same time, the flux in the solder paste will moisten the pads, component ends and pins.

2). When PCB enters the insulation zone, make PCB and components get fully preheated, in case PCB suddenly enters the welding high temperature zone and damages PCB and components.

3). When the PCB enters the welding zone, the temperature rises rapidly to make the solder paste melt, and the liquid solder wets, diffuses, diffuses or reflows the solder joints on the solder pads, component ends and pins of the PCB.

4).PCB enters the cooling zone to solidify the solder joint; The reflow soldering is completed.

Working principle of double track reflow soldering:

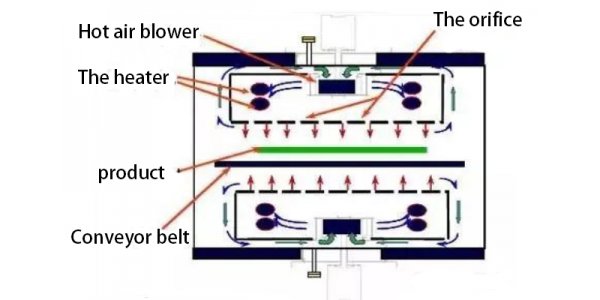

Double rail reflow furnace can double the capacity of a single double rail furnace by parallel processing two circuit boards at the same time. Currently, circuit board manufacturers are limited to handling identical or similar-weight circuit boards on each track. Now, a two-track, two-speed reflow furnace with independent track speeds makes it possible to process two more widely spaced circuit boards at the same time. First, we need to understand the main factors that affect the transfer of heat from the reflow heater to the circuit board. Normally, as shown, the fan of the reflow furnace pushes the gas (air or nitrogen) through the heating coil. The gas is heated and then transferred to the product through a series of orifices in the orifice plate.

1).The following equation can be used to describe the process of heat energy transfer from the airflow to the circuit board, q = heat energy transfer to the circuit board; A = convective heat transfer coefficient of circuit board and components; T = heating time of the circuit board; A = heat transfer surface area; Δ T = convection temperature difference between gas and circuit board we will move to formula one side of the circuit board related parameters, and reflow furnace parameters will be moved to the other side, can get the following formula: q = a | T | a | | T.

2).Double-track reflow PCB has been very popular and is becoming increasingly popular. The main reason for its popularity is that it provides designers with extremely good elastic space to design smaller, compact and low-cost products. As of today, double-track reflow boards are typically reflowed to the top (component surface) and then to the bottom (pilot surface) by wave soldering. A current trend is toward double - track reflow soldering. The bottom component of the large plate may fall off during the second reflow, or a partial melting of the bottom weld may cause solder joint reliability problems.

Introduction to reflow welding process:

Reflow welding process for the surface mount of the board, the process is relatively complex, can be divided into two: one side mount, two side mount.

1) one-side mounting: pre-applied solder paste → patch (divided into manual mounting and machine automatic mounting) → reflow soldering → inspection and electrical testing.

2). Double-sided mounting: pre-applied solder paste on side A → patch (divided into manual paste and machine automatic paste) → reflow soldering → pre-applied solder paste on side B → patch (divided into manual paste and machine automatic paste) → reflow soldering → inspection and electrical test.

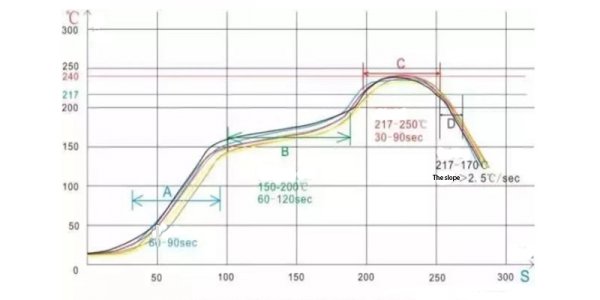

The simplest process of reflow soldering is "silk screen solder paste - patch - reflow soldering, its core is the accuracy of the silk screen, the patch is determined by the machine PPM yield, reflow soldering is to control the temperature rise and the highest temperature and the temperature drop curve.

Reflow welding process requirements:

Reflow soldering technology is not new in the field of electronic manufacturing. The components on various board CARDS used in our computers are welded to the circuit board through this process. The advantage of this process is that the temperature is easy to control, the welding process can also avoid oxidation, manufacturing costs are easier to control. Inside the device is a heating circuit that heats nitrogen to a high enough temperature to blow on the already attached circuit board, allowing solder on both sides of the device to melt and bond to the motherboard.

1). Reasonable reflow welding temperature curve should be set and real-time test of the temperature curve should be conducted regularly.

2). Welding shall be carried out according to the welding direction of PCB design.

3) strictly prevent the conveyor belt from vibration during the welding process.

4). The welding effect of the first PCB must be checked.

5). Whether the welding is sufficient, whether the surface of the welding spot is smooth, whether the welding spot is shaped like a half moon, the situation of tin balls and residues, the situation of continuous welding and virtual welding. Also check the color change on the PCB surface. And adjust the temperature curve according to the inspection result. Check the welding quality regularly during batch production.

Factors affecting the process:

1) generally, compared with a discrete chip element, PLCC and QFP have larger heat capacity, and it is more difficult to weld large-area elements than small ones.

2). In the reflow welding furnace, the conveyor belt is used as a heat dissipation system when reflow welding is carried out on every side. In addition, the edge of the heating part is different from the central heat dissipation condition, and the temperature at the edge is generally low.

3). Different effects of product loading. The temperature curve of reflow soldering should be adjusted to achieve good repeatability under no load, load and different load factors. Load factor is defined as LF=L/(L+S); Where L= the length of the assembled substrate, S= the interval of the assembled substrate. The larger the load factor, the more difficult it is to get good repeatability in reflow soldering process. Generally, the maximum load factor of reflow furnace is 0.5~0.9. This depends on the product (welding density of components, different substrate) and different types of reflow furnace. Practical experience is important to achieve good welding results and repeatability.