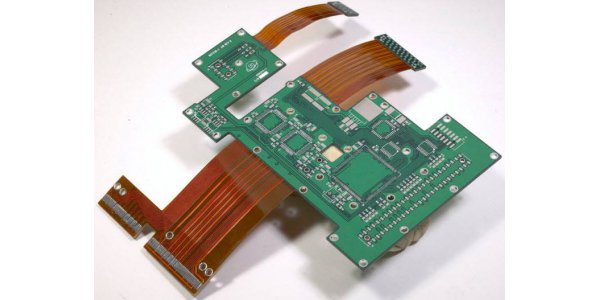

1. FPC is divided into double-sided FPC process and multi-layer FPC process according to the number of layers.

FPC can withstand millions of times of dynamic bending without damaging the wires. It can be arbitrarily arranged according to the spatial layout requirements, and can be moved and retracted in three dimensions to achieve the integration of component assembly and wire connection. The flexible circuit board can be greatly reduced. The volume and weight of electronic products are suitable for the development of electronic products in the direction of high density, miniaturization and high reliability.

Adhesive flexible board and non-adhesive flexible board.

Among them, the price of glue-free flexible board is much higher than that of glued flexible board, but its parameters such as flexibility, bonding force of copper foil and substrate, and flatness of pads are also better than those of glued flexible board. Therefore, it is generally only used in those places with high requirements, such as: COF (CHIP ON FLEX, mounting bare chips on flexible boards, and requiring high pad flatness).

Due to its high price, most of the flexible boards currently used in the market are still glued flexible boards.

Since FPC is mainly used in situations where bending is required, if the design or process is unreasonable, defects such as micro-cracks and open welding are prone to occur. The following is about the structure of FPC and its special requirements in design and technology.

3. Flexible board structure:

According to the number of layers of conductive copper foil, it is divided into single-layer board, double-layer board, multi-layer board, double-sided board and so on.

3.1. Single-layer board: The flexible board of this structure is the flexible board of the simplest structure. Usually the base material + transparent glue + copper foil is a set of purchased raw materials, and the protective film + transparent glue is another purchased raw material.First, the copper foil is subjected to processes such as etching to obtain the required circuits, and the protective film is drilled to expose the corresponding pads. After cleaning, the two are combined by rolling.

Then, the exposed pad portion is plated with gold or tin for protection. In this way, the big board is ready. Generally, a small circuit board is punched into a corresponding shape.

There is also a solder resist layer printed directly on the copper foil without a protective film, so the cost will be lower, but the mechanical strength of the circuit board will be poor. Unless the strength is not high but the price needs to be as low as possible, it is best to apply a protective film.

3.2. Double-layer board: When the circuit of the circuit is too complicated, single-layer board cannot be wired, or copper foil is needed for ground shielding, you need to choose double-layer board or even multilayer board.

Double-layer board structure: There are pads on both sides of the double-sided board, which is mainly used for connection with other circuit boards. Although it is similar in structure to a single-layer board, the manufacturing process varies widely. Its raw materials are copper foil, protective film + transparent glue. First, drill holes in the protective film according to the requirements of the pad position, then paste the copper foil, and etch out the protective film after drilling the pads and leads.

3.3. The most typical difference between a multi-layer board and a single-layer board is the addition of a via structure to connect the copper foil layers. The first processing technology of general substrate + transparent glue + copper foil is to make vias. Drill holes in the substrate and copper foil first, and then plate a certain thickness of copper after cleaning, and the via holes will be completed. The subsequent manufacturing process is almost the same as the single-layer board.

4. Material properties and selection methods

4. 1. Substrate:

The material is polyimide (POLYMIDE), which is a high temperature resistant, high strength polymer material. It can withstand a temperature of 400 degrees Celsius for 10 seconds and a tensile strength of 15,000-30, 000 PSI.

25 μm thick substrates are the cheapest and most commonly used. If the circuit board needs to be a bit harder, a 50 μm substrate should be used. Conversely, if the circuit board needs to be a little softer, a 13 μm substrate is used.

4. 2. Transparent glue for the substrate:

Divided into epoxy resin and polyethylene, both of which are thermosetting adhesives. The strength of polyethylene is relatively low. If you want a softer circuit board, choose polyethylene.

The thicker the substrate and the transparent adhesive thereon, the harder the circuit board. If the circuit board has a large area of bending, you should try to use a thinner substrate and transparent adhesive to reduce the stress on the surface of the copper foil, so that the copper foil is less likely to have microcracks. Of course, for such areas, single-layer boards should be used whenever possible.

4. 3. Copper foil:

Divided into rolled copper and electrolytic copper. The rolled copper has high strength and resistance to bending, but it is more expensive. Electrolytic copper is much cheaper, but has poor strength and is easy to break. It is generally used in places where it is rarely bent.

The choice of copper foil thickness depends on the minimum width of the leads and the minimum pitch. The thinner the copper foil, the smaller the minimum width and spacing that can be achieved.

When selecting rolled copper, pay attention to the rolling direction of the copper foil. The rolling direction of the copper foil should be consistent with the main bending direction of the circuit board.

4. 4. Protective film and its transparent adhesive:

Similarly, a 25μm protective film makes the circuit board harder, but it is cheaper. For circuit boards with large bends, a 13 μm protective film is best.

Transparent glue is also divided into epoxy resin and polyethylene. Circuit boards using epoxy resin are relatively hard. After the hot pressing is completed, some transparent adhesive will be extruded from the edge of the protective film. If the pad size is larger than the opening size of the protective film, this extruded adhesive will reduce the pad size and cause irregular edges. At this time, a transparent adhesive with a thickness of 13 μm should be selected as much as possible.

4. 5. Pad plating:

For circuit boards with large bends and exposed pads, electroplated nickel + electroless gold plating should be used. The nickel layer should be as thin as possible: 0.5-2 μm, and the chemical gold layer is 0.05-0.1 μm.

5. Design of pads and leads

5.1 SMT pad:

Ordinary pads: Prevent microcracks.

Reinforced pads: If pads are required to be very strong or reinforced design is required.

LED pads: Due to the high requirements on the location of the LEDs and the stress often applied during the assembly process, the pads must be specially designed.

QFP, SOP or BGA pads: Due to the large pad stress at the corners, strengthen the design.

5.2 Lead:

In order to avoid stress concentration, the lead should avoid a right-angle corner, and should use an arc-shaped corner.

To avoid stress concentration, the leads near the corners of the outline of the circuit board should be designed as follows:

6. Design of external interface

6.1 Circuit board design at solder hole or plug:

Because the welding hole or plug has a large stress during the plug-in operation, a reinforced design must be performed to avoid cracks.

Reinforcement board is used to increase the hardness of the solder joint of the circuit board. The thickness is generally 0.2-0.3mm, and the material is polyimide, PET or metal. For pad plating, it is better to choose electroplated nickel + hard gold for the plug and electroplated nickel + chemical gold for the solder hole.

6.2 Design of hot-pressed welding place:

Generally used for the connection of two flexible boards or flexible boards to hard circuit boards.

If it is necessary to bend the circuit board near the thermal bonding area, apply polyimide tape or glue on this area to prevent the pad root from breaking.

6.3 Design of ACF hot-pressing place: Design of stamped holes and small circuit board corners

7. Design for SMT:

7.1 Component orientation:

The length of the component should avoid the bending direction of the flexible board.

7.2 For large QFP or BGA, the reinforcing board should be pasted on the reverse side of the flexible board or the IC should be glued.

The material of the reinforcing plate is FR4, the thickness is greater than 0.2 mm, and the area is larger than the outer edge of the component by 0.5 mm.

7.3 Two positioning holes shall be made on the flexible board near the edge. You also need to make two patches to identify the pads. The diameter is 1 mm and the distance from other pads is at least 3.5 mm. The surface is plated with gold or tin, and the flatness is better.

7.4 If the large flexible board is composed of many small boards, each small board shall be a circular (3.2 mm inner diameter) bad circuit board identification pad. If the small circuit board is damaged, use a black marker to blacken the identification pad to avoid future operations.

7.5 The minimum distance between components from the edge of the board is 2.5 mm, and the minimum distance between components is 0.5 mm.

7.6 Do not have vias under the component, because the flux will flow through the vias and cause contamination.

8. Design for electrical performance

8.1 Relationship between maximum current and line width and line height

8.2 Control of impedance and noise:

Use transparent insulation, such as polyethylene. Avoid using epoxy.

In high impedance or high frequency circuits, increase the distance between the lead and the ground plane.

9. Special design of SMT process

9.1 Positioning methods in solder paste and placement process:

Because the flexible board is very thin and flexible, if the edge of the circuit board is used for positioning, the positioning accuracy is very poor. Positioning holes should be used. In order to avoid the leakage plate when printing the solder paste, a support plate with a spring pin is used.

9.2 Solder paste, patch, overheating furnace until the visual inspection is completed, the support plate is used to fix the whole process. To avoid solder joint damage during operation.