1. What is SMT Stencil?

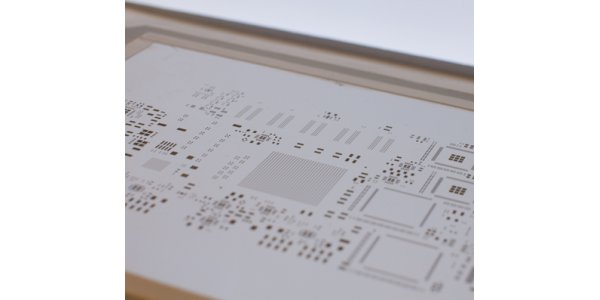

SMT stencil is also called steel plate. Its main function is to help solder paste deposition. It transfers the accurate amount of solder paste through the stencil port to the accurate pad position on the bare PCB. The quality of the stencil will affect the amount and shape of solder paste missing on the pad.

The steel mesh consists of a wire frame, a wire mesh and a steel sheet. There are many holes in the steel sheet. The positions of these holes correspond to the positions on the PCB that need to be printed. When in use, place the PCB under the stencil and leak the solder paste onto the PCB through the small holes in the fixed position on the stencil. The less solder paste is blocked on the stencil, the more it is deposited on the PCB. Therefore, when a bad situation occurs in the printing process, the condition of the steel plate should be checked first.

2. Is it possible to open the stencil only through the PCB?

2.1. Conventionally, a PCB file or a gerber file is required. The solder paste layer is exported using the PCB file and then used to open the stencil.2.2. Circuit board manufacturers can provide stencil files, because the imposition spacing is defined by the circuit board factory, unless you open a single piece.

2.3. It is best to ask the circuit board factory for the stencil file.

3. Four ways to identify the quality of SMT stencil

The stencil openings are small and thin. It is difficult to judge the quality of the stencils. There are four main factors affecting the quality of the stencils: the shape of the openings, the size of the openings, the width-thickness ratio and the area ratio.3.1 Check whether the material of the steel mesh is made of stainless steel.

3.2 Aspect ratio / Area ratio of stencil design

When printing, it is important to prevent the stencil from blocking. When designing the opening of the stencil, the window length is less than 5 times the width, that is, when L <5W, the aspect ratio is considered, and the other is the area ratio. Aspect ratio = stencil width / stencil thickness = W / H. For leaded printing, in order to make the stencil have good printability, the width-to-thickness ratio is required to be greater than 1.5; while for lead-free printing, the lead-free solder paste has a small specific gravity and poor wettability, so the opening is larger and the width-to-thickness ratio > 1.7.

If the window length is more than 5 times the width, that is, L> 5W, consider the area ratio, area ratio = window area / window hole wall area = L * W / [2 (L + W) H]. For leaded printing, in order to make the stencil have good printability, the area ratio is required to be greater than 0.66. In lead-free printing, the lead-free solder paste has a small specific gravity and poor wettability, so the opening is larger and the area ratio is larger > 0.7.

3.3 Whether the shape of the opening meets the requirements and whether there are obvious defects in the appearance quality of the mesh.

There are many opening shapes of the steel mesh plate, which are usually rectangular, square, and circular. Among them, rectangular openings have better demoulding efficiency than square and circular openings. Rectangular openings have vertical openings. In the type of downward, the stencil in the actual production should not have the shape of the opening of the bell mouth upward, because the shape of the opening of the bell mouth upward is likely to cause demolding.

3.4 Check whether the hole wall is smooth and has no burrs. Focus on checking the processing quality of the narrow-pitch IC pin openings.

In order to control quality problems such as solder balls or bridges during the welding process, the stencil opening size is usually slightly smaller than the pad size, especially for fine-pitch devices, the opening width should be reduced by 15% compared to the corresponding pad width 20%.

4. What are the uses of SMT stencils, and how do I use them?

A stencil is used in the first step of the PCBA patch process. The role of the stencil is to leak the solder paste to the corresponding pad of the circuit board through the opening of the stencil. First, the stencil is placed on the circuit board, then the stirred solder paste is placed on the stencil, and finally the solder paste is squeezed by a scraper and dropped onto the pad of the circuit board through the stencil port.Stencils are used to print red glue or solder paste on PCB boards. Steel meshes generally include solder paste and red glue nets. At the beginning, it is necessary to align the steel mesh with the PCB board, and then print the solder paste or red glue. After that the process is different. The solder paste net is a solder paste process. The holes that open correspond to the pads of the PCB board. Let the solder paste be printed on the pads, and then paste the parts. The reflow soldering is used to heat-fix. The red plastic mesh is an opening corresponding to the middle position of the component on the PCB board (need to avoid the tin pad), then paste the component on, heat it to cure the red plastic, and then pass through a tin furnace to solder.

5. What should I pay attention to when accepting SMT stencils?

5.1. Check whether the method and size of the steel mesh opening meet the requirements5.2. Check whether the thickness of the steel mesh meets the product requirements

5.3. Check whether the frame size of the steel mesh is correct

5.4. Check whether the marking of the steel mesh is complete

5.5. Check whether the flatness of the steel mesh is level

5.6. Check if the tension of the steel mesh is OK

5.7. Check whether the position and quantity of steel mesh openings are consistent with the GERBER file

6. The following 6 precautions need to be paid attention to during the use of SMT stencil

6.1 Keep the SMT stencil cleanThe steel mesh should be washed (wiped) before use to remove the dirt carried during transportation.

After the steel mesh is used up, it should be cleaned in time and returned to the packing box and placed on a special storage rack.

The steel mesh should be placed vertically in a dedicated shelf, and the plates should be separated from each other (film can be pasted). It is forbidden to stack and contact each other. Stencils waiting to be cleaned should not be placed at will to avoid accidental damage.

6.2 The solder paste or red glue should be stirred evenly to avoid blocking the steel mesh.

6.3 SMT stencils are generally very delicate. Handle them gently. Do not hit the stencil with hard objects or sharp knives.

6.4 Printing pressure

The printing pressure is adjusted to the best: the pressure when the scraper can just scrape the solder paste (red plastic) on the steel net is the best

It is best to use overlay printing when printing

6.5 Printing speed

After the scraper stroke is completed, if possible, it is best to stop for 2 to 3 seconds before demolding, and the demolding speed should not be too fast.

6.6 SMT steel mesh usage

The service life of the steel mesh should be specified and monitored by effective methods. The steel mesh that has exceeded the service life should be scrapped. (Typically 100,000 times).