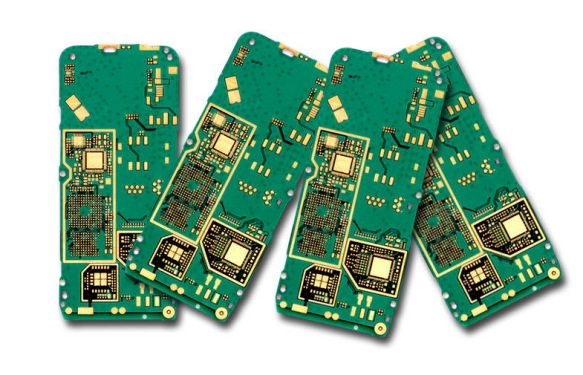

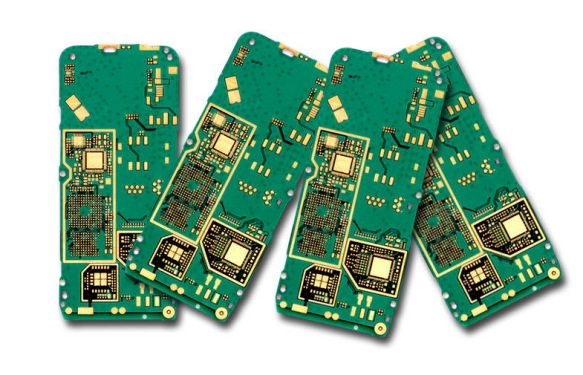

Immersion Gold PCB

Immersion gold is the process of chemical deposition, through chemical oxidation and reduction reaction on the surface of circuit board to produce a layer of metal coating.

Why should we use immersion gold?

Copper on the circuit board is mainly copper, copper solder joints are easily oxidized in the air which will lead to poor electrical conductivity or poor contact with tin, and reduce the performance of the circuit board, then it is necessary to surface treatment of copper solder joints, gold deposit is on the top of gold plating, gold can effectively prevent copper metal and air. Gold deposit is a kind of surface anti-oxidation treatment. It is coated with gold by chemical reaction on the surface of copper. It is also called gold deposit.

What are the advantages of immersion gold?

The advantage of the gold deposition process is that the deposited color on the printed circuit surface is very stable, the brightness is very good, the coating is very flat, and the weldability is very good. The thickness of gold deposit is 1-3 Uinch, so the gold deposit is generally thicker. So gold deposit is widely used in keyboard, golden finger board and other circuit boards because of its strong conductivity, good oxidation resistance and long service life.

What are the advantages of using immersion gold PCBs?

1. The immersion gold PCB is color bright, good in color and appearance.

2. The crystal structure formed by immersion gold is easier to solder than other surface treatments, which can have better performance and ensure quality.

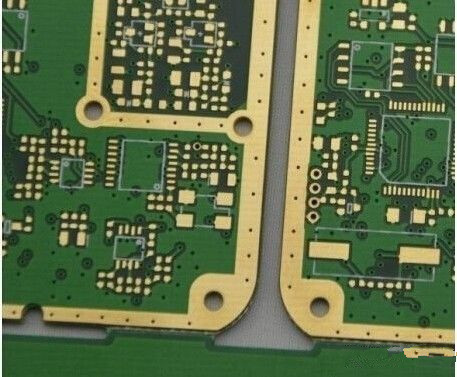

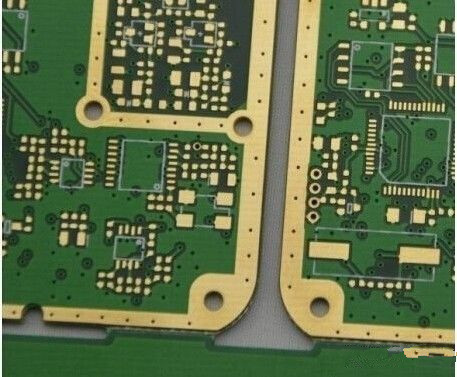

3. Because immersion gold board only has nickel and gold on the pad, it will not affect the signal, because the signal transmission in the skin effectis in the copper layer.

4. The properties of gold are relatively stable, the crystal structure is more compact and the oxidation reaction is not easy to occur.

5. Because only the pad of the sunken gold plate has nickel and gold, the combination of resistance welding and copper layer on the circuit is stronger, and it is not easy to cause micro-short circuit.

6. The distance will not be affected when the project is compensated.

7. The stress of sunken gold plate is easier to control.

The golden finger is a brass contact or conductor. In detail, because gold is highly antioxidant and conductive, so the parts connected with the memory slot on the memory bar are plated with gold, then all signals are transmitted through the golden finger. The golden finger is named because it consists of many yellow conductive contacts, whose surface is gold-plated and arranged like fingers. The golden finger is a connecting part between the memory bar and the memory slot. All signals are transmitted through the golden finger. The golden finger is made up of many golden electric contacts. The golden finger is actually covered with gold through a special process on the copper clad laminate.

Therefore, a simple distinction is that immersion gold is a surface treatment process of circuit boards, and gold finger is a component with signal connection and conduction on circuit boards. In market practice, golden fingers may not really be gold on the surface. Because of the high cost of gold, more memory is replaced by tin plating. Tin material has been popular since 1990s. At present, the "golden finger" of motherboard, memory and graphics card is almost all tin material. Only parts of high performance server/workstation contact points will continue to be used. Gold plating is naturally expensive.