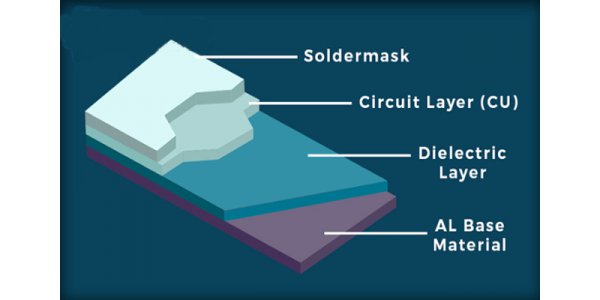

Aluminum PCB is a kind of metal base copper clad plate with good heat dissipation function. Generally, the single panel is composed of three layers, namely circuit layer (copper foil), insulation layer and metal base layer. For high-end use, there are also double-sided boards designed, with the structure of circuit layer, insulation layer, aluminum base, insulation layer and circuit layer. Very few applications are multi-layer boards, which can be made of common multi-layer boards, insulation layer and aluminum base.

Aluminum based copper clad laminate is a kind of metal circuit board material, which is composed of copper foil, thermal insulation layer and metal substrate.

There are three layers:

(1) Circuit layer: equivalent to common copper clad plate, the thickness of copper foil is 10oz.

(2) Dielectric layer: it is low thermal resistance insulation material.

(3) Base: it is a metal substrate, usually aluminum or copper.

The circuit layer is etched to form a printed circuit interconnecting each part of the component. Generally, the circuit layer is required to have a large current carrying capacity, so a thick copper foil with a thickness of 35 μ m to 280 μ m should be used.

The thermal dielectric layer is the core technology of aluminum substrate, which has the ability to resist thermal aging and bear mechanical and thermal stress. The insulating layer of high-performance aluminum substrate has excellent thermal conductivity and high-strength electrical insulation performance by using the technology.

Metal base is the support component of aluminum pcb, which needs high thermal conductivity. In general, you can use aluminum or copper plate (it can provide better thermal conductivity), which is suitable for drilling, punching and cutting.

Difference between LED aluminum substrate and PCB:

LED aluminum substrate is a kind of printed circuit board. It is printed on the aluminum plane with good thermal conductivity, and then the components are welded on it.

PCB is the abbreviation of printed circuit board. LED aluminum base plate and FR-4 glass fiber board belong to PCB. Compared with the FR-4 glass fiber circuit board, the difference between LED aluminum substrate and FR-4 glass fiber circuit board is that it uses aluminum based materials and its thermal conductivity is much better than that of ordinary FR4 materials. Because the good heat dissipation of aluminum substrate is suitable for the requirements of many high-power electrical appliances, most of the aluminum substrate is used in the production of LED lighting. FR-4 fiberglass circuit board is a traditional electronic product circuit board, which is widely used in communication, automobile, medical treatment, industrial control, security and other fields due to its good insulation, corrosion resistance, compression resistance, multi-layer printing and other characteristics.

The product quality of LED aluminum substrate mainly considers the material model, hardness, surface and thickness of aluminum material, and also selects the appropriate model and size according to the heat output of the product. FR-4 fiberglass circuit board is a relatively mature product, which is widely used in LED display.

At present, there are three kinds of circuit boards used in the field of lighting: FPC circuit board for the production of LED soft light strip; fiberglass plate for ordinary lighting products; and aluminum base for lighting products.

LED lighting circuit board:

Some applications need to have specific properties in their boards. This is especially true for temperature sensitive applications, one of which is led lighting. The LED lighting industry is expanding rapidly in response to interest in more efficient and cost-effective lighting methods, but most of the functionality of LED lights depends on the temperature of their systems. For many companies, the solution to this problem is based on aluminum pcb, which we call led PCB.

In order to help you understand the reason why led PCB is used in LED lighting industry, we have outlined the nature of PCB base, the attraction of aluminum pcb and the reason why they work well in LED lighting industry.

Led PCB has been widely used because of its energy saving and environmental protection. With years of turnkey service experience in PCB, component procurement and OEM PCB assembly, can rayming provide led PCB, LED chip and OEM led PCB assembly services. If you have some questions about led PCB.

PCB core:

Engineers design printed circuit boards to play the best role in their specific applications. The design can specify the nature of the circuit, PCB coating material, PCB size and various other qualities. However, one of the most fundamental changes is the core of the circuit board.

PCB base has a variety of materials, including:

FR-4: the most common of these materials is FR-4, a base consisting of glass and epoxy resin. Although FR-4 is flame retardant, its heat transfer efficiency is often relatively low.

Epoxy: another, though less common, PCB substrate is a material called epoxy. Although it is not as durable as other options, the manufacturing cost of epoxy PCB is much lower.

Metal core: metal core PCB is very effective for various applications, especially those involving heat transfer. These substrates are laminated with metal (usually aluminum) and copper. These metals provide better electrical insulation and thermal conductivity for circuit boards. When thermal mass is less important, FR-4 or epoxy base materials are more common because they are often relatively cheap. However, when thermal quality is important for the normal function of the final product, the metal core printed circuit board may be the solution.

Advantages of LED PCB

(1) more suitable for LED PCB processing technology;

(2) In the circuit design scheme, the thermal diffusion is effectively treated, so as to reduce the operating temperature of the module, extend the service life, and improve the power density and reliability;

(3) Reduce the assembly of radiators and other hardware, reduce the volume of products, and reduce the cost of hardware and assembly;

(4) replace the fragile ceramic substrate to obtain better mechanical durability.

The role of thermal conductivity of aluminum in PCB:

The heat dissipation of LED is the most headache for LED manufacturers, but it can be solved by using aluminum pcb, because aluminum has good thermal conductivity and strong heat dissipation ability, which can effectively export the internal heat. Aluminum PCB is a kind of unique copper plate covered with metal base, which has good thermal conductivity, electrical insulation and machining performance. In the design, PCB should also be close to the aluminum base as much as possible, so as to reduce the thermal resistance of the potting adhesive part.