PCBA Quality Analysis and Process Test Design

Posted: May 14, 2022

By: Bonnie

The uniform requirements for PCB assembly are consistency and correctness. Control the difference and do not allow mutation. Poor quality in the assembly manufacturing process comes from three aspects: design problems, material problems, and assembly problems. The first two problems require advance measures to prevent them from occurring. Most of the problems in the assembly process, such as missing parts, damaged parts, wrong parts, and offsets, can be checked visually, but the welding quality is difficult to judge visually. Sometimes PCBA is delivered to customers, and then malfunctions such as bombers, blasting boards, and poor functions occurred later. The main assembly failure mode is poor welding, which accounts for 57% of all assembly failures.

There are many types of testing technologies currently used in the field of electronic assembly testing. Commonly used are Manual Visual Inspection (MVI), In-Circuit Tester (ICT), Automatic Optical Inspection (AOI), Automatic X-ray Inspection (AXI), Function Tester, referred to as FCT.

They can be classified into two categories according to whether the PCBA is powered on: one is electrical test technology, and the other is non-electrical test technology.

It can also be divided into two categories according to whether the PCBA is in contact with the test equipment: one is contact testing technology, and the other is non-contact testing technology.

Traditional visual inspection of the PCB assembly process does not completely eliminate poor soldering, but also requires automatic X-ray non-destructive testing. But the investment in additional equipment is large. After the circuit board is assembled by SMT, it will first use AOI to use optical to check the problems such as part shift, short circuit, tombstone, missing parts, etc., then pass the circuit test of ICT or MDA, and then pass the functional verification test (FVT). There are three ways to verify that the board is functioning properly.

However, with the development and application of SMT processing, electronic products are developing in the direction of lightness, thinness, and miniaturization. The density of PCBA has become higher and higher with the continuous miniaturization of components. The mutual obstruction of densely populated components, as well as the micro-packages (0201) and "invisible" solder joints (such as BGA, CSP, and flip chip component FCA) that have appeared widely in recent years. The quality of PCBA processing cannot be guaranteed.

Someone once conducted such a test, which allowed four experienced inspectors to perform four inspections on the solder joint quality of the same board (medium complexity circuit board, such as a 300-component, 3500-node single panel). As a result, the first inspector found 44% of the defects, the second inspector agreed with the first 28%, and the third inspector agreed with the first two 12%. The fourth inspector is only 6% consistent with the first three. This test exposed the subjectivity of manual visual inspection, which was neither reliable nor economical. At present, in artificial manufacturing, the manual visual test method is only used as a supplementary auxiliary method.

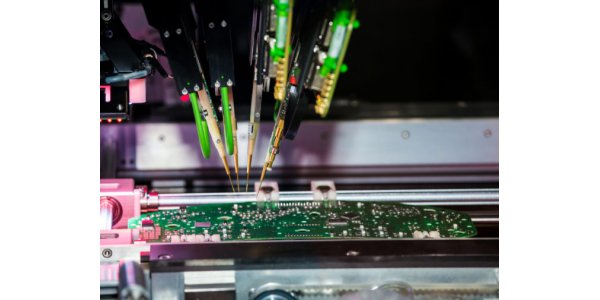

When the online tester measures, use a special flying probe to contact the components on the soldered PCBA board, and perform discrete isolation tests with hundreds of millivolts and currents within 10 milliamps, so as to accurately measure the installed resistance and inductance , capacitors, diodes, triodes, thyristors, window effect transistors, integrated blocks and other general and special components are missing, misinstalled, parameter value deviations, solder joints, circuit boards open and short and other faults, and which component or open-short is located at which point exactly.

The biggest advantage of flying probe test is that the trial production response is fast, but the detection speed is slow, which is suitable for testing samples and small batch orders. If it is required to make samples, you can choose to fly the needle test, and then change the fixture test until you make a large batch order, to avoid the change process or cancel the order of the fixture production cost investment.

The strengths of ICT are electrical defect testing, such as device malfunction or incorrect values. Online testing can effectively find various defects and faults that occur during the assembly process, but it cannot fully evaluate the electrical performance of PCBA.

ICT needs PCB design to meet ICT testability design requirements, and it is more troublesome to implement the diverse levels of PCBA processing. In addition, the more the number of nodes tested by PCBA, the cost will increase sharply, mainly due to the design and manufacture of needle beds or flying probes. When the number of nodes exceeds the ICT requirements, when the physical size of the PCBA exceeds the ICT requirements, the problem will be more difficult to solve.

The miniaturization of electronic products has directly led to the miniaturization (high-density integration) of PCBA board design, and the value of PCBA design for ICT testing will disappear. This means that manufacturing will face a large number of potential problems. PCB assembly directly into the final inspection will not only lead to a decline in the qualification rate, increase in repairs and fault diagnosis costs, but also cause production delays.

ICT can be tested without powering on the PCBA to be tested, which can avoid the risk of circuit board burnout. Then power on when you want to perform the low-level test.

The FVT must be powered on before it can be tested, and the circuit board may be burned due to a shorted part.

3.2. Do they need test points

ICT all uses test points for testing, but you can use nodes (Nets) to reduce the number of test points.

FVT only needs some test points, or use IO to connect IO device (monitor, network cable or card reader)

3.3. Ease of debugging defective products

As long as there are test points for ICT, it can pinpoint which part or node has the problem, and it is convenient for the operator to repair the defective board.

FVT can't tell exactly which part is defective, it can only rely on experience or hire a professional repair technician to repair the defective board.

3.4. Bypass circuit test capability

As long as ICT has test points, bypass circuits can also be tested.

Unless the FVT can simulate special conditions, it is difficult for the bypass circuit to test and confirm the quality.

3.5. Short / Open test for all of the nets.

As long as ICT has test points, it can test all parts or nodes.

FVT can only check the product function by powering on.

3.6. Components for L, C, R, D, Tr (measure characteristic values of inductance, capacitance, resistance, diode, transistor)

As long as ICT has test points, all passive component characteristics can be measured.

FVT can only check the product function by powering on. If something is wrong or the feature is missing, it may not be detected.

3.7. Characteristic measurement of active components (IC)

ICT can use test point measurement, or use JTAG or TestJet to reduce measurement points.

FVT detects product functions by turning on the power.

3.8. Measuring Frequency, Voltage.

ICT can.

FVT can.

3.9. Performing the Function test.

ICT can perform low-level functional self-tests. It can only detect most of the functions, but it is not possible to check whether the screen display is normal and the IO reading is correct, such as FVT, because it is not a real test

FVT uses test points or real insertion to test all functions once, but only functions under normal conditions.

3.10. Test time

ICT Generally, a board can be tested in one minute, or even as short as 10 seconds.

FVT generally takes a few minutes to complete the test, because some human operations can not be avoided.

3.11. Do they need to download the test program first?

ICT does not need to download test programs to perform open-short and passive component characteristic tests. If it is to perform low-level program tests, it must be installed or downloaded in advance.

FVT needs to download the operating system and test program before it can start the test.

3.12. Does it support OTG downloader

ICT downloaded operating system or program into circuit board memory.

FVT support.

Actually compare the test time and man-hour cost of [ICT + Sampling FVT] and [Pure FVT]

Here we use the same board to compare the test time difference between [100% ICT + 5% FVT sampling] and [NO ICT + 100% FVT]. The results and projects of each company will be different. The reason why [5% FVT sampling] is adopted is because there is a whole machine test to cover later.

The comparison results show that the test time of [NO ICT + 100% FVT] took a total of 310s, while [ICT + 5% FVT sampling] only took 67s. Dollar charge by Factory Support US $ 10 / hour Assuming that the factory's working hours are US $ 10 per hour, Monthly spend Support 100,000 output per moth has a production of 100,000 tablets per month, so the monthly working hours cost is US $ 67,500 (= 86100 -18600).

Calculation results: using ICT test saves money than using FVT alone

There are many types of testing technologies currently used in the field of electronic assembly testing. Commonly used are Manual Visual Inspection (MVI), In-Circuit Tester (ICT), Automatic Optical Inspection (AOI), Automatic X-ray Inspection (AXI), Function Tester, referred to as FCT.

They can be classified into two categories according to whether the PCBA is powered on: one is electrical test technology, and the other is non-electrical test technology.

It can also be divided into two categories according to whether the PCBA is in contact with the test equipment: one is contact testing technology, and the other is non-contact testing technology.

Traditional visual inspection of the PCB assembly process does not completely eliminate poor soldering, but also requires automatic X-ray non-destructive testing. But the investment in additional equipment is large. After the circuit board is assembled by SMT, it will first use AOI to use optical to check the problems such as part shift, short circuit, tombstone, missing parts, etc., then pass the circuit test of ICT or MDA, and then pass the functional verification test (FVT). There are three ways to verify that the board is functioning properly.

1. MVI technology in PCB assembly

MVI is to confirm the quality of component placement, insertion, and soldering on PCBA through human visual comparison. The operator's eyes are used to look at the goods, supplemented by a magnifying glass and a microscope.However, with the development and application of SMT processing, electronic products are developing in the direction of lightness, thinness, and miniaturization. The density of PCBA has become higher and higher with the continuous miniaturization of components. The mutual obstruction of densely populated components, as well as the micro-packages (0201) and "invisible" solder joints (such as BGA, CSP, and flip chip component FCA) that have appeared widely in recent years. The quality of PCBA processing cannot be guaranteed.

Someone once conducted such a test, which allowed four experienced inspectors to perform four inspections on the solder joint quality of the same board (medium complexity circuit board, such as a 300-component, 3500-node single panel). As a result, the first inspector found 44% of the defects, the second inspector agreed with the first 28%, and the third inspector agreed with the first two 12%. The fourth inspector is only 6% consistent with the first three. This test exposed the subjectivity of manual visual inspection, which was neither reliable nor economical. At present, in artificial manufacturing, the manual visual test method is only used as a supplementary auxiliary method.

2. ICT Technology in PCBA Assembly

The online tester is also called flying probe tester. Its principle is to test the electrical properties and electrical connections of the assembled PCBA board-on-board components to check manufacturing defects and component failures.When the online tester measures, use a special flying probe to contact the components on the soldered PCBA board, and perform discrete isolation tests with hundreds of millivolts and currents within 10 milliamps, so as to accurately measure the installed resistance and inductance , capacitors, diodes, triodes, thyristors, window effect transistors, integrated blocks and other general and special components are missing, misinstalled, parameter value deviations, solder joints, circuit boards open and short and other faults, and which component or open-short is located at which point exactly.

The biggest advantage of flying probe test is that the trial production response is fast, but the detection speed is slow, which is suitable for testing samples and small batch orders. If it is required to make samples, you can choose to fly the needle test, and then change the fixture test until you make a large batch order, to avoid the change process or cancel the order of the fixture production cost investment.

The strengths of ICT are electrical defect testing, such as device malfunction or incorrect values. Online testing can effectively find various defects and faults that occur during the assembly process, but it cannot fully evaluate the electrical performance of PCBA.

ICT needs PCB design to meet ICT testability design requirements, and it is more troublesome to implement the diverse levels of PCBA processing. In addition, the more the number of nodes tested by PCBA, the cost will increase sharply, mainly due to the design and manufacture of needle beds or flying probes. When the number of nodes exceeds the ICT requirements, when the physical size of the PCBA exceeds the ICT requirements, the problem will be more difficult to solve.

The miniaturization of electronic products has directly led to the miniaturization (high-density integration) of PCBA board design, and the value of PCBA design for ICT testing will disappear. This means that manufacturing will face a large number of potential problems. PCB assembly directly into the final inspection will not only lead to a decline in the qualification rate, increase in repairs and fault diagnosis costs, but also cause production delays.

3. The test differences between ICT and FVT are listed below.

3.1. Do they need to power on the testICT can be tested without powering on the PCBA to be tested, which can avoid the risk of circuit board burnout. Then power on when you want to perform the low-level test.

The FVT must be powered on before it can be tested, and the circuit board may be burned due to a shorted part.

3.2. Do they need test points

ICT all uses test points for testing, but you can use nodes (Nets) to reduce the number of test points.

FVT only needs some test points, or use IO to connect IO device (monitor, network cable or card reader)

3.3. Ease of debugging defective products

As long as there are test points for ICT, it can pinpoint which part or node has the problem, and it is convenient for the operator to repair the defective board.

FVT can't tell exactly which part is defective, it can only rely on experience or hire a professional repair technician to repair the defective board.

3.4. Bypass circuit test capability

As long as ICT has test points, bypass circuits can also be tested.

Unless the FVT can simulate special conditions, it is difficult for the bypass circuit to test and confirm the quality.

3.5. Short / Open test for all of the nets.

As long as ICT has test points, it can test all parts or nodes.

FVT can only check the product function by powering on.

3.6. Components for L, C, R, D, Tr (measure characteristic values of inductance, capacitance, resistance, diode, transistor)

As long as ICT has test points, all passive component characteristics can be measured.

FVT can only check the product function by powering on. If something is wrong or the feature is missing, it may not be detected.

3.7. Characteristic measurement of active components (IC)

ICT can use test point measurement, or use JTAG or TestJet to reduce measurement points.

FVT detects product functions by turning on the power.

3.8. Measuring Frequency, Voltage.

ICT can.

FVT can.

3.9. Performing the Function test.

ICT can perform low-level functional self-tests. It can only detect most of the functions, but it is not possible to check whether the screen display is normal and the IO reading is correct, such as FVT, because it is not a real test

FVT uses test points or real insertion to test all functions once, but only functions under normal conditions.

3.10. Test time

ICT Generally, a board can be tested in one minute, or even as short as 10 seconds.

FVT generally takes a few minutes to complete the test, because some human operations can not be avoided.

3.11. Do they need to download the test program first?

ICT does not need to download test programs to perform open-short and passive component characteristic tests. If it is to perform low-level program tests, it must be installed or downloaded in advance.

FVT needs to download the operating system and test program before it can start the test.

3.12. Does it support OTG downloader

ICT downloaded operating system or program into circuit board memory.

FVT support.

Actually compare the test time and man-hour cost of [ICT + Sampling FVT] and [Pure FVT]

Here we use the same board to compare the test time difference between [100% ICT + 5% FVT sampling] and [NO ICT + 100% FVT]. The results and projects of each company will be different. The reason why [5% FVT sampling] is adopted is because there is a whole machine test to cover later.

The comparison results show that the test time of [NO ICT + 100% FVT] took a total of 310s, while [ICT + 5% FVT sampling] only took 67s. Dollar charge by Factory Support US $ 10 / hour Assuming that the factory's working hours are US $ 10 per hour, Monthly spend Support 100,000 output per moth has a production of 100,000 tablets per month, so the monthly working hours cost is US $ 67,500 (= 86100 -18600).

Calculation results: using ICT test saves money than using FVT alone

ICT is still more suitable for mass-produced models. If it is relatively small or there are not so many ICs and other active parts on the board, maybe only MDA is needed. If it is less than 1,000 boards per month, it may even be considered tested with AOI and FVT only.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

14

)

14

791

1

Share to: