1. Analysis of the origin and characteristics of Surface mount adhesives

Adheasive is widely used in SMT chip processing, mainly to meet the process requirements of SMT chip component and DIP Plug-in component that require tin on the same side. If the traditional Solder Paste is used for SMT placement, and the plug-in soldering is performed by wave soldering with the Plug-in component, the solidified tin on the chip component pad will be melted by liquid tin water, causing the chip component to fall off.

For example, many power boards require chip components and plug-in components to be tinned on the same side, and all use Surface mount adhesives.

2. Production process of Surface mount adhesives

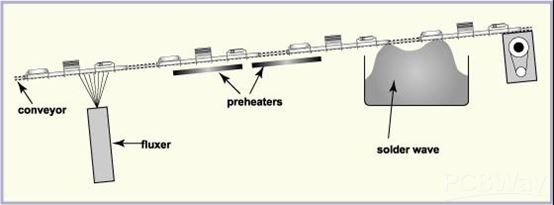

Adheasive is a soft paste state at normal temperature. You can place Adheasive in the middle of two or more PCB pads, and then paste the chip component on Adheasive. After reflow, Adhaasive cures quickly, holding the component tightly. After the next DIP plug-in process, the plug-in component and the chip component receive the impact of the soldering water from the wave soldering, thereby tinning the pads of the entire PCB. After the PCB board flows through wave soldering, it cools down quickly, and all components can be firmly soldered to the pads.In other words, Surface mount adhesives are wave soldering of chip component and Plug-in component together.

3. Surface mount adhesives quality control

1.Control the preheating temperature to ensure that Adhesives can get the right temperature;2.Check whether the PCB pads are dirty with oxidation or green oil;

3.Check whether the bottom of PCB and components is metal, and there are no residual adhesives;

4.In wave soldering, the metal is not easy to conduct heat too quickly. If it is too fast, the cured Adhesives will be exposed to high temperature again, and its adhesion will be instantly reduced, leading to dropped parts.

4. What is the fundamental difference between Reflow Soldering Adheasive and Solder Paste?

1.Adheasive plays a fixed role and does not conduct electricity. Solder Paste also plays a fixed role, but will have a conductive role;2.Adheasive needs to be wave soldered before welding

3. The temperature of Adheasive wave soldering is lower than that of Solder Paste wave soldering.

4.Adheasive is generally used as an auxiliary material, generally used for fixing, because Solder Paste can be conductive, so it is often used when welding.

5. How to choose which process?

1.It mainly depends on the use of materials in product design:Adheasive is fixed by heating and curing, and Paste is soldered by heating and melting tin. There is a fundamental difference in the Reflow temperature between the two.

When there is no traditional Plug-in component, a solder paste process is used (including single-sided, double-sided or multi-layer boards).

There is a single panel with traditional components, and the solder side will use the Adhesaive process.

One side has the traditional Adheasive double panel, one side will use the solder paste process, and the other solder side will use the Adheasive process.

The Adheasive process must pass the wave soldering process to complete the welding of the parts and PWB. The process is slightly longer and the cost is increased. The solder paste process is completed by reflow soldering. The process is relatively short, saving costs, and the product production cycle is short.

2.The role of red solder + solder paste reflow process

In the mixed process of SMT processing and DIP plug-in, in order to avoid the one-sided reflow once and the wave once to pass through the furnace twice, the chip components on the wave soldering surface of the PCB need to be red glue, which can be used once during wave soldering Soldering tin, eliminating its solder paste printing process. However, there are many problems with red rubber in general. And the most secure red plastic + solder paste dual process, the cost is a bit high. The temperature of reflow soldering of red plastic products is better controlled, and it is difficult to solder in the wave. Solder paste products are soldered in reflow soldering machines, and the temperature parameters are relatively difficult.