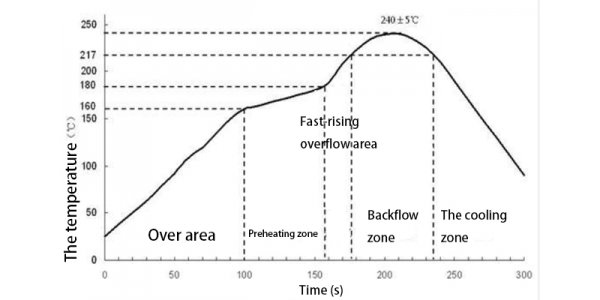

Reflow welding mainly consists of four temperature zones: heating zone, constant temperature zone, welding zone and cooling zone. This is a reflection of the paste paste installed on the circuit board in the reflow soldering process.

Reflow soldering is mainly used with SMT process technology, in the SMT process, is the main purpose of reflow soldering will stick with components of the PCB board inside the orbit of reflow welding machine, after cooling, heating, heat preservation, welding, solder paste from cream after high temperature into a liquid, then through cooling into solid form, so as to realize the role of SMD electronic components and PCB welding.

Reflow welder, also known as reflow welder, reflow welding, refers to the same equipment. The function of reflow welding is to realize the welding of PCB board and components, which has the function of high production efficiency, few welding defects and stable performance. It is an important welding equipment in PCBA processing plant.

1).Function of reflow soldering heating zone:

The heating zone is in the first stage of reflow welder welding. The PCB board should be preheated and heated, the solder paste should be activated, part of the solvent should be volatilized, and the moisture of the PCB board and components should be evaporated and cleaned to eliminate the stress in the PCB board.

2).Function of reflow soldering insulation zone:

PCB board into the insulation area, reach a certain temperature, prevent sudden entry into the welding high temperature area, damage PCB board and components. The role of this temperature zone is also to keep the temperature of components stable, make the temperature of components of different sizes on the PCB board is always the same, reduce the temperature difference of the whole PCB board, and the solder paste in the volatile clean, remove the oxide of the solder pad and components pin.

3).Function of reflow welding zone:

PCB board into the welding area, the temperature reached the highest, then the solder paste from paste has become liquid, fully infiltrate the solder pad, components pin, the duration of this link is relatively short, to prevent high temperature damage PCB board and components.

4).Effect of reflow soldering cooling zone:

After the solder paste becomes liquid, then it can be cooled, the faster the cooling speed is better, the cooling speed is too slow, easy to produce gray roughness, generally cooled to 75℃ on the curing, then the realization of the PCB board welding.

How to choose reflow soldering:

1). See the thermal insulation performance of reflow welding furnace:

Good reflow welding furnace, its thermal insulation performance is good, high thermal efficiency, poor reflow welding furnace thermal insulation performance can not meet the requirements. Although furnace thermal efficiency is difficult to measure, but it can use hand touch reflow furnace and exhaust pipe shell to determine temperature at work, usually there are cooling parts, when touch feel hot or dare not to touch that furnace heat preservation performance is poor, large energy consumption, normal, people feel a slight fever (about 50 degrees Celsius).

2). Evaluation of reflow furnace temperature:

The evaluation of reflow furnace temperature is an important step in the selection of reflow furnace, and the following methods are usually adopted for the evaluation:

(1) the temperature in the cross section of the furnace chamber is uniform

Open the reflow furnace track to the maximum position, place a PCB, and set 5 ~ 6 test points along the cross section of the furnace on the PCB to measure the temperature difference of the plate surface when there is no load, the temperature difference should be less than 0.5 ℃. Then continuously put the PCB (full load), measure the temperature of the board surface of the last PCB (the same as the first one), in order to identify the temperature difference on the PCB when full load, generally in plus or minus 1 ℃. The third step is to place different analog IC blocks on the PCB and test them. This determination is effective in detecting the temperature change at full load of the reflow furnace, while observing the actual temperature change shown on the reflow gauge, which should normally not exceed plus or minus 1 °c.

(2) resolution of longitudinal (motion direction) temperature of furnace chamber

If you take a 20cm * 20cm PCB, place it on three thermocouples, and test the furnace temperature curve. The measured temperature curve should clearly reflect the dislocation state of the thermocouple on the PCB, that is, before (direction of motion) the thermocouple reaches the high temperature area first, then the high temperature area, the hierarchy is clear.

3). See the type of reflow heater:

Generally can be divided into two categories, one is by the infrared lamp and adapt to the lamp tube heater, they can directly radiate heat, also known as a radiation body; The other is ceramic plate, aluminum plate and stainless steel plate type heater.

Tubular heater: it has the advantages of high working temperature, short radiation wavelength and relatively fast heat. However, due to the generation of light during heating, it has different reflection effects on components with different colors of welding. Meanwhile, it is not conducive to supporting with forced hot air.

Plate heater: the thermal response is slow, the efficiency is a little low, but because of the thermal inertia is large, through the perforation is conducive to hot air heating, the color sensitivity of the elements to be welded is small, the shadow effect is small, in addition, the current sales of reflow welding furnace, the heater is almost all aluminum plate or stainless steel heater.

4).Depending on the transport:

Good reflow welding process, in operation, the mesh belt is very stable without shaking, if there is a vibration phenomenon, will cause welding spot shift, suspension bridge, cold welding and other welding defects.

5).Professional testing and evaluation:

In addition to the above intuitive selection methods, there are also some professional testing and evaluation. Whether the reflow soldering equipment can be included in the purchase plan, there are also some operating parameters to consider.