Classification of substrates for PCB

1) According to different reinforcement materials (the most commonly used classification method) version

™Gamma Paper substrate weight (FR-1, FR-2, fr-3)

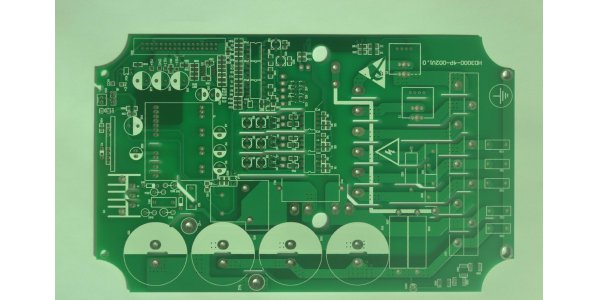

™Gamma Epoxy glass fiber cloth substrate (FR-4, FR-5)

™Gamma Composite substrate (CEM-1, CEM-3) Gamma

HDI sheet (RCC) Gamma

Special base materials (metal base material, ceramic base material, thermoplastic base material, etc.)

2) According to different resins Gamma

Phenolic resin board

™Gamma Epoxy resin board

™Gamma Polyester resin board

™Gamma BT resin board

™Gamma PI resin board

3) According to the flame retardancy

™Gamma Flame retardant (ul94-vo, ul94-v1)

™Gamma Non flame retardant (ul94-hb)

|

Type |

Material quality |

Features |

Main difference from fault |

Price |

PCB color |

|

FR-4 |

Fiberglass board |

1) FR-4 is made of copper foil and epoxy resin glass fiber cloth 2) Its raw material is made of imported electronic grade glass fiber cloth, which is an important base material for making multilayer printed circuit board 3) It has high mechanical and dielectric properties, good heat resistance and moisture resistance, and good machinability |

The section of FR-4 epoxy board is sandwiched in the middle with gray glass fiber cloth |

High |

We can hardly judge the difference in surface color, mainly from the area above the fault |

|

CEM-1 |

Semi fiberglass board with glass fiber cloth on both sides and paper in the middle (computer punching only) |

Single side fiberglass board (computer drilling is necessary, die punching is not allowed) |

There is white resin in the middle of CEM-1 fault |

Low |

We can hardly judge the difference in surface color, mainly from the area above the fault |

|

22F |

Single side semi fiberglass board (die punching) |

The material structure of 22F CCL is the same as CEM-1 board, which is made of semi glass fiber board (the surface of the board is glass fiber cloth, and the middle is wood pulp paper) |

There is white resin in the middle of 22F fault |

The price is cheaper than CEM-1 |

We can hardly judge the difference in surface color, mainly from the area above the fault |

|

CEM-3 |

Double sided semi fiberglass board |

1)CEM-3 is different from FR-4 in that it adopts glass cloth and glass mat composite substrate, also known as composite base material, rather than pure glass cloth 2)The thermal expansion is greater than FR-4 3) Performance is constantly improving, popular up to take a period of time, with good prospects |

It is really difficult to distinguish CEM-1, CEM-3 and 22F from the appearance. At most, it is from the side blade of PCB board |

About 10-15% cheaper than FR-4 |

Surface color: CEM-1 is yellow than CEM-3 |

|

Remarks |

PCB is divided from bottom to top according to brand quality level: 94hb-94vo-22f-cem-1-cem-3-fr-4 |

|

|

|

|