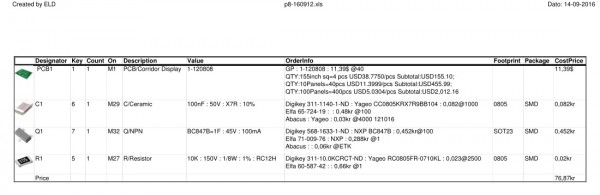

PCB bill of material (BOM) is used to express the composition structure relationship of raw materials, parts or semi-finished products. The BOM list is formed by combining various test data and component models, parameters, specifications and so on. To judge the accuracy of this list, different judgment standards will guarantee the accuracy of BOM list. The accuracy of BOM is usually judged strictly, and the single-layer structure is often taken as the unit for statistics. If there is any discrepancy, the accuracy of the layer structure will be judged as 0. The accuracy of BOM is guaranteed to the greatest extent.

At first usually need to prepare a piece of white paper and a pen. Writing down the serial number and the position number of components on the paper. After each component is removed, paste it on the white paper with double-sided adhesive tape. However, attention should be paid to the number arrangement of the components in the process of splitting the board, because the error of the position information of one component may lead to the inaccuracy of the whole BOM list and affect the result. After getting the sequence list recording the information of components, we enter the production process of BOM. Through testing and analysis, we summarize all the relevant parameters of components into information table. Now we need to introduce a professional testing equipment -- bridge tester. This tester mainly analyzes the impedance of various components. It is a kind of measuring instrument of technical specifications. It uses comparison method to measure the resistance, capacitance and inductance of components. Different bridge test equipment has different test effect and accuracy.

Generally speaking, the bridge tester has reference standards such as measuring accuracy, measuring range and measuring speed. The tester with high measurement accuracy, wide measurement frequency range and fast measurement speed cannot only ensure higher accuracy, but also improve the intensity and efficiency of measurement. Advanced enterprises are applied to the automatic balance bridge technology with the widest range of impedance measurement. The measurement accuracy reaches 0.05%, and the maximum measurement speed is 30 times per second. It can measure 22 kinds of impedance parameter combinations, and has the function of 10 point list scanning test.

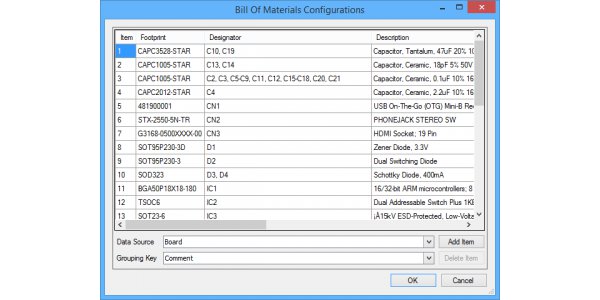

1. Select "production / manufacturing data / BOM / BOM". Click the "add" button on the toolbar.

2. After selecting the BOM, the system will automatically bring out the product and process route. You can also select the product first, and the system will automatically default the product number and name to the BOM. In general, if a product has only one BOM, you can set the BOM number and name to be the same as the product's.

3. Enter other information of BOM. In particular, the version number can be obtained automatically by clicking "coding rules". The version number can be automatically generated by the system and must be defined in the coding rule definition.

4. Click the "add" button to save the data.

5. During the saving process, an interface will pop up. Click "open document".

6. Click "Edit" on the routing to synchronize the routing, add new operations, and review the routing

7. Click "Edit" on the material consumption plan to add new materials and review the material consumption plan. Before editing the material consumption plan, ensure that there is at least one operation in the process route. When adding materials, you need to select the corresponding operation.

8. Click "audit" on the toolbar to audit the whole BOM. If the BOM routing and BOM material plan have been approved, you must also click audit here to audit the BOM master. At this point, BOM production is completed.