Detailed Explanation of BOM (Bill of Material)

Posted: May 13, 2022

By: Bonnie

1. Item

Item or Material is a collective name for inventory. It is a prerequisite for establishing BOM and other business data. It is called Item master data in the ERP system. It includes Raw material, Work in Process (WIP), and Semi-finished products ( semi-product), finished goods, tools, accessories, etc.

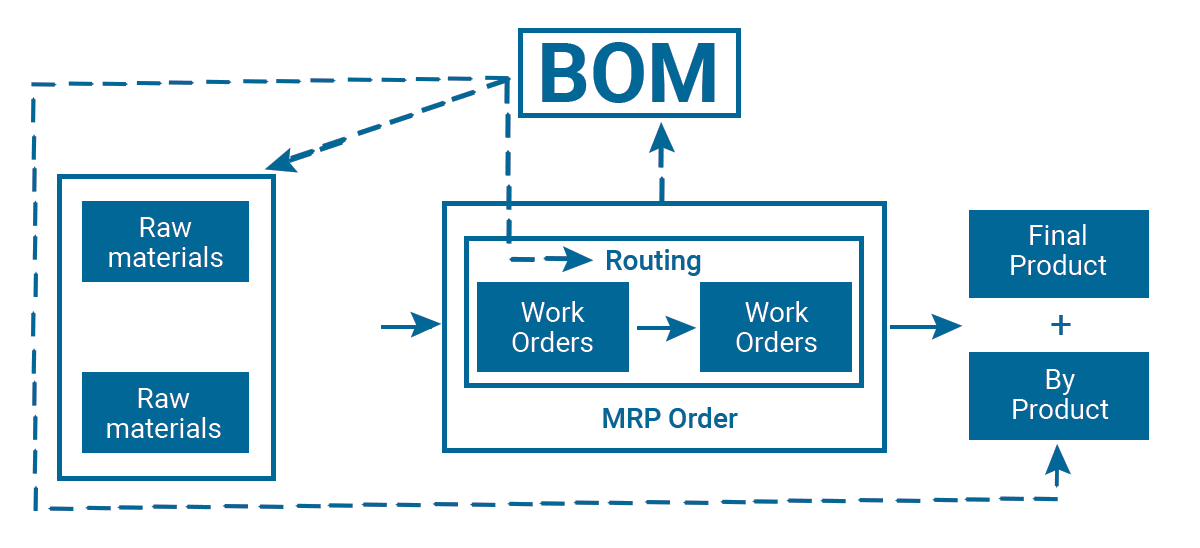

Bill of Materials, also known as the product structure table, product structure tree, parts list. The cost bill of materials is extended on the basis of the BOM. The BOM is developed by R & D personnel, PE and production management personnel. Jointly prepared product structure table. The BOM not only lists all the materials required to produce a product, but also ranks where each material is located in the product structure. Not only the level, number, specifications, and units of each material are marked, but also the standard amount (STD qty) of each material in the product, whether it is a homemade part or an outsourced part, is listed.

3. The main constituent elements of BOM:

3.1 BOM Level: BOM is compiled according to the anti-process route. The level of materials reflects the processing order of products. The lowest level is raw material, the next lowest level is rough parts (WIP), the upwards are semi-products, and the topmost level is finished goods. That is, layer 0. The purchased parts and components involved in the final assembly are on the first floor.

3.2 Item code (Item or Part no): Also commonly known as material number, product number, etc. Part no is a material sequence number arranged according to certain coding rules. There are multiple methods for coding rules, such as Arabic numerals, English letters, hints, mixed methods, etc. A material can only have one Part no. Similarly, a Part no can only represent one material, as if our ID card. Although they have the same name, the ID numbers are different. This is the unique requirement of Part no.

3.3 Item Description: Also called the item name, it is a description of the material characteristics. For example, the material description of 36-00-R40031 is 980D5 / DC5 datasheet.

3.4 Specification or Type: A product may have multiple types, and different types of materials, even if there are slight differences, are considered as another material. The product cost is calculated separately. The product type is the smallest unit of the material. Some ERP systems process the name + Type = Item Description in a field.

3.5 Unit of Measure: Unit of Measure is grams, kilograms, pieces, sets, liters, bags, etc. A material may have multiple Unit of Measure at the same time, generally the smallest unit is the basic unit. That is, the inventory unit, if it is required to set Unit of Measure conversion factor or called conversion factor in the ERP software when purchasing or selling.

3.6 Standard Quantity: Standard Quantity on the BOM table can be divided into input quantity and output quantity. Output is the net amount that makes up the finished product. The Standard Quantity setting of the same product can be different at different production stages. For example, the production of plastic low-shell requires 2.2 tons of ABS material and 0.51 tons of toner at one time. At this time, the material amount setting is best to use the input amount. A certain part was damaged during the process, and a sporadic picking list (bulk list) was issued to replace one. The relationship between input volume and output volume is: input volume = output volume * (1 + scrap rate).

3.7 Phantom item: The use of Phantom item is mainly to reduce the number of layers and complexity of the BOM and simplify the operation of MPS. Of course, it is also for the convenience of business management, such as reducing MO (Manufacturing Order). There are many disadvantages to using Phantom item in large quantities, especially Phantom item set for the convenience of a department to see the product structure. The use of Phantom item needs to be careful because the impact of Phantom item on the system is very large, and it has an impact on the production, execution and management of work orders. It may be difficult for the workshop to adapt to this situation.

Is Phantom item in stock, there are two cases:

1. No inventory is allowed.

Item or Material is a collective name for inventory. It is a prerequisite for establishing BOM and other business data. It is called Item master data in the ERP system. It includes Raw material, Work in Process (WIP), and Semi-finished products ( semi-product), finished goods, tools, accessories, etc.

Bill of Materials, also known as the product structure table, product structure tree, parts list. The cost bill of materials is extended on the basis of the BOM. The BOM is developed by R & D personnel, PE and production management personnel. Jointly prepared product structure table. The BOM not only lists all the materials required to produce a product, but also ranks where each material is located in the product structure. Not only the level, number, specifications, and units of each material are marked, but also the standard amount (STD qty) of each material in the product, whether it is a homemade part or an outsourced part, is listed.

3. The main constituent elements of BOM:

3.1 BOM Level: BOM is compiled according to the anti-process route. The level of materials reflects the processing order of products. The lowest level is raw material, the next lowest level is rough parts (WIP), the upwards are semi-products, and the topmost level is finished goods. That is, layer 0. The purchased parts and components involved in the final assembly are on the first floor.

3.2 Item code (Item or Part no): Also commonly known as material number, product number, etc. Part no is a material sequence number arranged according to certain coding rules. There are multiple methods for coding rules, such as Arabic numerals, English letters, hints, mixed methods, etc. A material can only have one Part no. Similarly, a Part no can only represent one material, as if our ID card. Although they have the same name, the ID numbers are different. This is the unique requirement of Part no.

3.3 Item Description: Also called the item name, it is a description of the material characteristics. For example, the material description of 36-00-R40031 is 980D5 / DC5 datasheet.

3.4 Specification or Type: A product may have multiple types, and different types of materials, even if there are slight differences, are considered as another material. The product cost is calculated separately. The product type is the smallest unit of the material. Some ERP systems process the name + Type = Item Description in a field.

3.5 Unit of Measure: Unit of Measure is grams, kilograms, pieces, sets, liters, bags, etc. A material may have multiple Unit of Measure at the same time, generally the smallest unit is the basic unit. That is, the inventory unit, if it is required to set Unit of Measure conversion factor or called conversion factor in the ERP software when purchasing or selling.

3.6 Standard Quantity: Standard Quantity on the BOM table can be divided into input quantity and output quantity. Output is the net amount that makes up the finished product. The Standard Quantity setting of the same product can be different at different production stages. For example, the production of plastic low-shell requires 2.2 tons of ABS material and 0.51 tons of toner at one time. At this time, the material amount setting is best to use the input amount. A certain part was damaged during the process, and a sporadic picking list (bulk list) was issued to replace one. The relationship between input volume and output volume is: input volume = output volume * (1 + scrap rate).

3.7 Phantom item: The use of Phantom item is mainly to reduce the number of layers and complexity of the BOM and simplify the operation of MPS. Of course, it is also for the convenience of business management, such as reducing MO (Manufacturing Order). There are many disadvantages to using Phantom item in large quantities, especially Phantom item set for the convenience of a department to see the product structure. The use of Phantom item needs to be careful because the impact of Phantom item on the system is very large, and it has an impact on the production, execution and management of work orders. It may be difficult for the workshop to adapt to this situation.

Is Phantom item in stock, there are two cases:

1. No inventory is allowed.

2. Inventory is allowed, if the premise is an option, that is, the relationship between the main material and the substitute material. If the main material is in stock, the main material is preferred. If the main material inventory is 0, the alternative material is considered.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

13

)

13

390

1

Share to: