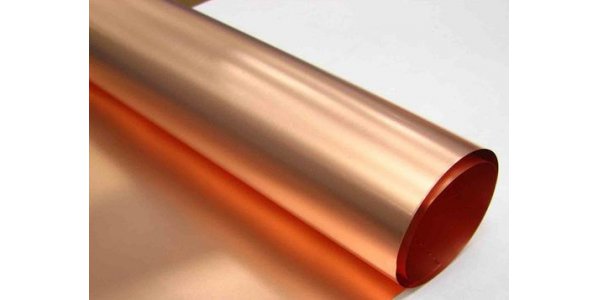

Copper foil is the main raw material for the manufacture of CCL, and CCL is the main raw material for the manufacture of printed circuit board (PCB). At present, most of the copper foil is used to make printed circuit board. With the development of PCB in the direction of multi-layer, thin, high-density and high-speed, copper foil is also developing in the direction of ultra-thin, low profile, high strength, high ductility and other high-quality and high-performance. According to the thickness of copper foil, it can be divided into thick copper foil (more than 70 m), conventional thickness copper foil (more than 18 m but less than 70 m), thin copper foil (more than 12 Λ m but less than 18 Λ m), ultra-thin copper foil (less than 12 Λ m); according to the surface treatment, it can be divided into single-sided treatment copper foil, double-sided treatment copper foil and adhesive coated copper foil; according to the production method, it can be divided into electrolytic copper foil and calendered copper foil. Electrolytic copper foil is formed by the deposition of copper ions in the electrolyte on the smooth rotating stainless steel plate (or titanium plate) circular cathode drum. The surface of the wool foil close to the surface of the cathode drum is called smooth surface, and the other side is called rough surface. The calendered copper foil is generally made of copper ingot as raw material, through hot pressing, tempering and toughening, planing and descaling, cold rolling, continuous toughening, pickling, calendering, degreasing and drying processes, The roughness of rolled copper foil is 01 Λ m, and that of electrolytic copper foil is 013 Λ m. In addition, the purity of rolled copper foil is 99.9%, and that of electrolytic copper foil is 99.8%

Electrolytic copper foil is formed by the deposition of copper ions in the electrolyte on the smooth rotating stainless steel plate (or titanium plate) circular cathode drum. The surface of copper foil close to the cathode drum is called smooth surface, while the other side is called rough surface.In the process of electrolytic copper foil production, the treated copper material needs to be added into the copper dissolving tank. The larger the surface area of the copper material is, the better. There should be a small gap between the copper materials to increase the reaction area. After adding a certain amount of pure water and sulfuric acid, compressed air is introduced for oxidation reaction to generate copper sulfate solution. The chemical reaction formula is 2Cu + 2h2so4 + O2 = 2CuSO4 + 2H2O. The reaction is a solid-liquid, solid gas, liquid gas multiphase reaction. The reaction speed is related to the total surface area of copper in the tank. The larger the surface area is, the faster the reaction speed will be. Secondly, it is related to the air volume. The air volume is increased and the reaction speed is also accelerated. The thinner the copper foil is, the higher the quality grade is, the lower the impurity content in the electrolyte is required. In order to ensure the quality of copper foil, the purity of copper must be greater than 99.9%.

Copper sulfate is used as electrolyte in the manufacture of raw foil, and its main components are Cu2 + and H+. Under the action of direct current, the cation moves to the cathode and the anion moves to the anode. Two electrons are reduced to Cu by Cu2 + on the cathode, and the raw foil is formed by crystallization on the cathode roller. After electrolysis, the Cu2 + content of the electrolyte decreased and the H2SO4 content increased. When the electrolyte is returned to the copper dissolving tank for adjustment, Cu2 + in the electrolyte increases while the content of H2SO4 decreases. The content of Cu2 + and H2SO4 in the electrolyte is in equilibrium by electrolysis and copper dissolution.