According to JPCA-es-01-2003 standard: copper clad laminates with chlorine (C1) and bromine (BR) content less than 0.09% wt (weight ratio), are defined as halogen-free copper clad laminates.Halogen as a raw material has a huge negative impact, so it is necessary to ban halogen. At present, most of the halogen-free materials are mainly composed of phosphorus system and phosphorus nitrogen system. Phosphorus containing resin is highly dehydrated during combustion, which forms carbonized film on the surface of polymer resin, insulates the burning surface of resin from contacting with air, extinguishes the fire, and achieves flame retardant effect. The polymer resin containing phosphorus and nitrogen compounds can produce non combustible gas during combustion, which helps the resin system to be flame retardant.

1) Insulation

Because P or n is used to replace the halogen atom, the polarity of the molecular bond segment of epoxy resin is reduced to a certain extent, thus improving the insulation resistance and resistance to penetration of the material

.

2) Water absorption

Due to the fact that N and P in n-p-based deoxidizing resin have less electron to halogen, the probability of hydrogen bond between n-and P-based deoxidizing resin and hydrogen atom in water is lower than that of halogen-free material, so the water absorption of halogen-free material is lower than that of conventional halogen-based flame retardant material. For sheet metal, low water absorption has a certain impact on improving the reliability and stability of the material.

3) Thermal stability

The content of nitrogen and phosphorus in Halogen-free plate is higher than that of halogen in common halogen materials, so the molecular weight and TG value of monomer are increased. In the case of heating, the mobility of its molecules will be lower than that of conventional epoxy resin, so the thermal expansion coefficient of halogen-free materials is relatively small.

When applying halogen free solder paste on PCB, the ability of tin loading is worse than that of halogenated solder paste. But there are no hidden defects. The excellent performance of halogen-free solder paste will definitely replace the halogen-free solder paste in the future and achieve the leading position in the industry market.

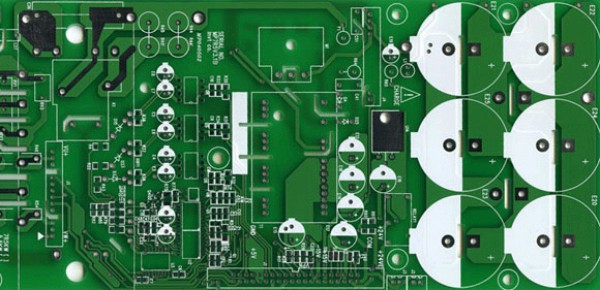

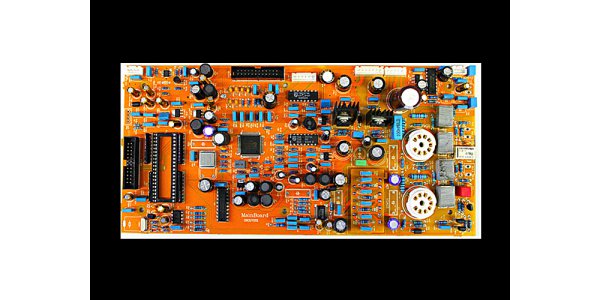

Due to its low water absorption and environmental protection requirements, halogen-free PCB can also meet the quality requirements of PCB in other properties. Therefore, the demand for halogen-free PCB has become larger and larger. In addition, the major board suppliers have also invested more funds in the research and development of halogen-free PCB and halogen-free pp. I believe that in the near future, low price halogen-free PCB will be put into the market immediately. Therefore, all PCB manufacturers should put the trial and use of halogen-free board on the agenda, make a detailed plan, and gradually expand the share of halogen-free board in the factory, so that they can go ahead of the market demand.