Depth and Width of the V-cuts/Grooves of PCB

Posted: May 14, 2022

By: Bonnie

Generally, the size of slotting cutter in PCB Factory is different, so you can consult AiPCBA before assembling, or let us finish the work for you. The position offset of upper and lower V slots (T1 and T2) is (d) ± 0.1 mm, and that of V groove (L) ± 0.3 mm.

Company inspection standard

|

Shape of single product |

Plate type |

Residual thickness of V groove (visual inspection) |

Remarks |

|

Rectangular plate |

XPC, FR-1 (paper substrate) 22F, CEM-1 (semi fiberglass board) FR-4 (fiberglass board), aluminum substrate |

One third of plate thickness |

The residual thickness of V groove of strip plate is one fourth of plate thickness |

|

Special shaped (triangular, circular) plate |

XPC, FR-1 (paper substrate) |

One third of plate thickness is reserved for V groove on process side and half plate thickness is reserved for V groove in middle |

|

|

|

22F, CEM-1 (semi glass fiber board) FR-4, aluminum substrate |

One third of plate thickness |

|

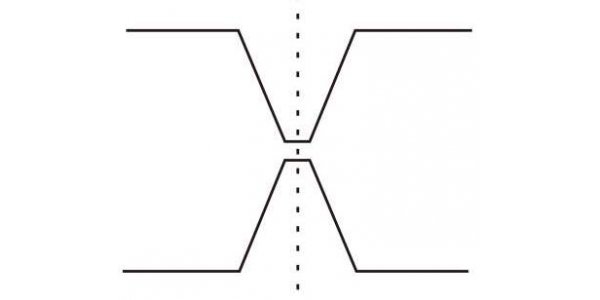

V-CUT

| Depth |

1 / 4 plate thickness at upper and lower depth, 1 / 2 plate thickness reserved, tolerance: ± 0.1 mm; FR-4 material, 1 / 3 plate thickness, 1 / 3 plate thickness reserved; |

available |

| Deviation |

Tolerance: ± 0.25mm (line to line, line to plate edge) |

available |

|

Upper and lower deviation |

Upper and lower tool deviation ≤ 7mil (0.178mm) |

available |

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

7

)

7

516

1

Share to: