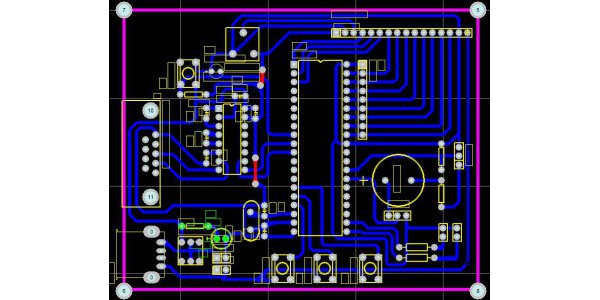

Flexible printed boards shall be designed in accordance with the provisions of standard. The general design drawing, photographic base and production base should include the figure of connecting plate for quality consistency inspection. The attachment plate shall be located not more than 13 mm and not less than 6.4 mm away from the plate edge, and shall reflect the whole manufacturing process, including the manufacturing process of the covering layer. In the design of flexible or rigid flex printed boards of types 3 and 4, the figure of attached boards for quality consistency inspection shall be placed in the most complex rigid or flexible part.

The general design drawing shall specify the type, size and shape of flexible and rigid flex printed boards, the location and size of all holes, whether there is concave corrosion, the location of traceability marks, the isolation and insulation layer between layers, the number and position of connecting boards for quality consistency inspection, the figure and arrangement of conductor and non conductor, or the shape and arrangement of components, and the view of each conductor layer of flexible and rigid flex printed boards. Drawings that are not controlled by hole size and hole location shall be dimensioned correctly, either specially or by annotation. When automation technology is specified in the contract or order, tapes or disks containing all the computer instructions required to manufacture each production substrate shall be provided.

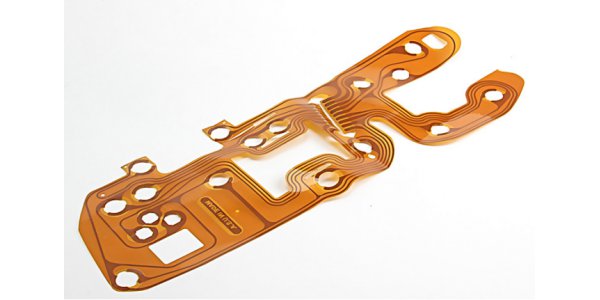

The thickness and width of wires on flexible printed boards shall be selected according to the current carrying capacity and allowable design temperature rise. In order to be easy to manufacture and improve the service life, the width and spacing of the conductor shall be the maximum value in accordance with the design requirements. The minimum conductor width marked on the general design drawing shall not be less than 0.10 mm. In order to achieve the wire width indicated in the general design drawing, compensation can be made in the production plate.

The thickness requirements of flexible printed boards shall be specified on the general design drawing, and the thickness measurement is required only for the areas requiring thickness control. The thickness of the installation area or surface contact area of the element, including the thickness of the coating, shall be specified. The thickness of the base material shall be measured in the area where the thickness of the base material is strictly required. The dimensional deviation shall be as wide as possible and specified on the general design drawing.

When the flexible printed boards of types 2, 3 and 4 processed consist of flexible metal clad insulation material, adhesive and covering insulation material, the thickness of the solidified insulation material layer (base material and adhesive) between adjacent conductor layers shall be at least 0.038 mm.

Flexible PCB is quoted according to the layout utilization rate and PCB is quoted directly according to the area of single board, so you need to know the quantity of one square meter of layout and the price can be obtained. Input the known quantity and other data in AiPCBA to get the most affordable quotation. Click the PCB quotation function at https://www.aipcba.com/ to get the result immediately.