High Frequency PCB Materials

Posted: May 14, 2022

By: Bonnie

Since circuit design tends to use high frequencies, stricter requirements are placed on the reliability of flexible printed circuit boards (FPC). Extending high frequencies quickly and efficiently requires optimizing the choice of materials, such as substrates, adhesives and copper foil. The basic characteristics of high-frequency substrate materials are as follows:

1) The dielectric constant (DK) must be small and stable. Generally, the smaller the signal, the better the signal transmission rate, and the inverse ratio of the square root of the dielectric constant of the material is. High dielectric constant can easily cause signal transmission delay.

2) The dielectric loss (DF) must be small, which mainly affects the quality of signal transmission. The smaller the dielectric loss, the smaller the signal loss.

3) The thermal expansion coefficient of copper foil should be as consistent as possible, because the inconsistency will lead to the separation of copper foil in the change of cold and heat.

4) Low water absorption rate and high water absorption rate will affect the dielectric constant and dielectric loss when damping.

5) Other heat resistance, chemical resistance, impact strength and peel strength must also be good.

In general, high frequency can be defined as frequencies above 1 GHz. At present, the most commonly used high-frequency circuit board substrate is a fluorine-based dielectric substrate, such as polytetrafluoroethylene (PTFE) commonly known as Teflon, which is usually used above 5 GHz. In addition, FR-4 or PPO substrates can be used for products between 1GHz and 10GHz.

In order to keep up with the rapid development of high-frequency circuit boards, it is necessary to cooperate with raw material suppliers, research units, equipment suppliers, PCB manufacturers and communication product manufacturers to develop the entire fluorine system high-frequency circuit boards.

1) The dielectric constant (DK) must be small and stable. Generally, the smaller the signal, the better the signal transmission rate, and the inverse ratio of the square root of the dielectric constant of the material is. High dielectric constant can easily cause signal transmission delay.

2) The dielectric loss (DF) must be small, which mainly affects the quality of signal transmission. The smaller the dielectric loss, the smaller the signal loss.

3) The thermal expansion coefficient of copper foil should be as consistent as possible, because the inconsistency will lead to the separation of copper foil in the change of cold and heat.

4) Low water absorption rate and high water absorption rate will affect the dielectric constant and dielectric loss when damping.

5) Other heat resistance, chemical resistance, impact strength and peel strength must also be good.

In general, high frequency can be defined as frequencies above 1 GHz. At present, the most commonly used high-frequency circuit board substrate is a fluorine-based dielectric substrate, such as polytetrafluoroethylene (PTFE) commonly known as Teflon, which is usually used above 5 GHz. In addition, FR-4 or PPO substrates can be used for products between 1GHz and 10GHz.

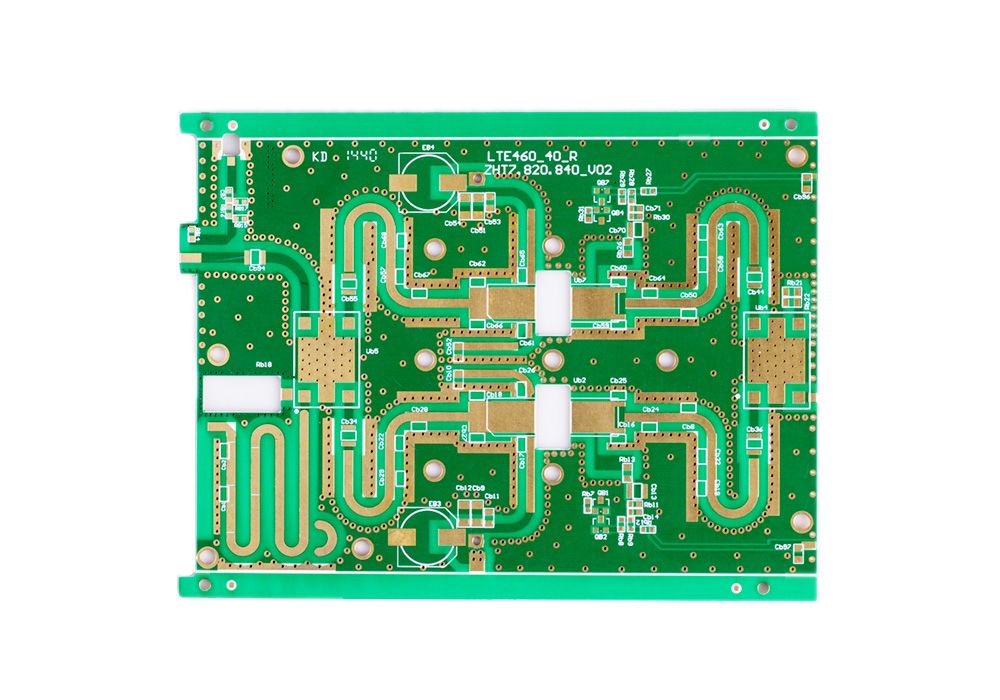

High frequency PCB

Epoxy resin, PPO resin and fluororesin are the three high-frequency substrate materials currently used. The cost of epoxy resin is the cheapest, while fluororesin is the most expensive. Considering the dielectric constant, dielectric loss, water absorption rate and frequency characteristics, fluororesin is the best and epoxy resin is the worst. When the product application frequency is higher than 10 GHz, only fluororesin printed boards can be used. Obviously, the performance of fluororesin high-frequency substrates is much higher than other substrates, but its disadvantages are not only high cost, but also poor rigidity and large coefficient of thermal expansion. For polytetrafluoroethylene (PTFE), a large amount of inorganic materials (such as silica SiO 2) or glass cloth are used as reinforcing filler materials to improve performance, thereby increasing the rigidity of the substrate and reducing its thermal expansion. In addition, due to the molecular inertia of Teflon resin itself, it is not easy to bond with copper foil, so special surface treatment is required. Perform chemical or plasma etching on the surface of PTFE to increase the surface roughness, or add a layer of adhesive film between the copper foil and PTFE resin to improve the adhesion, but it may affect the dielectric Performance has an impact. Due to the molecular inertia of PTFE resin itself, it is not easy to use it in combination with copper foil, so special surface treatment is required. Perform chemical or plasma etching on the surface of PTFE to increase the surface roughness, or add a layer of adhesive film between the copper foil and PTFE resin to improve the adhesion, but it may affect the dielectric Performance has an impact. Due to the molecular inertia of PTFE resin itself, it is not easy to use it in combination with copper foil, so special surface treatment is required. Perform chemical or plasma etching on the surface of PTFE to increase the surface roughness, or add a layer of adhesive film between the copper foil and PTFE resin to improve the adhesion, but it may affect the dielectric Performance has an impact.In order to keep up with the rapid development of high-frequency circuit boards, it is necessary to cooperate with raw material suppliers, research units, equipment suppliers, PCB manufacturers and communication product manufacturers to develop the entire fluorine system high-frequency circuit boards.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

12

)

12

466

3

Share to: