In order to ensure the welding quality in the circuit welding process, flux (paste) should be used. Generally, flux (paste) cannot be completely volatilized in the welding process, and there will be residues left on the board. Whether the residue needs to be cleaned or not needs to be removed, it needs to be comprehensively considered according to the quality of the selected flux, product requirements, and production costs and other factors. When the used flux (paste) has a lot of residue, viscosity and corrosiveness after welding, and the insulation resistance cannot meet the requirements, which will affect the electrical performance and three prevention performance of the weldment, the method of cleaning must be taken to remove the flux residue.

Cleaning flux (paste) is very important to ensure the reliability of the circuit, because the residue of flux (paste) not only affects the appearance of PCB, but also may cause short circuit and corrosion, reducing or damaging the quality of PCB. When choosing the cleaning agent for album, the factors that need to be considered are: the type of flux, the compatibility of cleaning agent, the difficulty of operation, etc. In the classification of flux, the cleaning methods are divided into: Rosin washable, rosin non washable, non washable and non washable. For the washable flux, there is no residue after cleaning, which can achieve the basic performance of electrical appliances. However, the residue on the board surface after the non cleanable flux welding cannot be cleaned by the cleaning agent, and it is easy to form white residue, and at the same time, it will lead to the decrease of insulation resistance value on the board surface and affect the test pass rate.

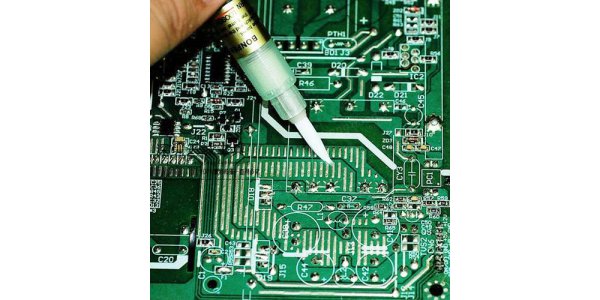

1) Manual cleaning

Use hand tools to clean residual flux and dirt on the solder joint. The manual cleaning method is suitable for all kinds of welding points. The method is simple and effective, but the efficiency is low. Hand cleaning tools commonly used are brush, brush, tweezers, cotton yarn and so on. During cleaning, it is necessary to pay attention not to damage the welding points and components. The cleaning action should be light. Do not twist and pull the wires on the welding points or lead wires of components. And the cleaning fluid should not be dispersed, do not use excessive cleaning fluid, to prevent the cleaning fluid from flowing inside the product and reduce the performance of the product. At the same time, when the cleaning fluid becomes dirty, it should be replaced in time. Cleaning fluid is usually flammable chemicals, and attention should be paid to fire prevention when using.

2) Ultrasonic cleaning

Ultrasonic cleaning is a method that uses the cleaning effect produced by high frequency oscillation of ultrasonic wave to complete the cleaning, which is completed by ultrasonic cleaning agent. Under the action of ultrasonic wave, the cleaning fluid produces cavitation effect. The high-strength shock wave generated by cavitation effect can separate the dirt on the welding point and in the slit, and accelerate the process of dissolving the dirt by the cleaning fluid. Ultrasonic cleaning method has the advantages of fast cleaning speed, good cleaning quality, and can clean the dirt in complex welding parts and crevices. The effect of ultrasonic cleaning is related to many factors, such as ultrasonic frequency, sound intensity, nature of cleaning solution, temperature and cleaning time.