SMT products have the advantages of compact structure, small volume, vibration resistance, impact resistance, high frequency characteristics and high production efficiency. SMT has already occupied a position in the PCB assembly process. The typical SMT process is divided into three steps: solder paste application, component placement and reflow soldering. Because reflow process has the characteristics of "reflow" and "self positioning effect”, the requirements of reflow process on mounting accuracy are relatively loose, and it is easy to realize the high automation and high speed of welding. At the same time, due to the characteristics of reflow and self positioning effect, reflow soldering process has more strict requirements on pad design, component standardization, quality of component end and PCB, solder quality and process parameters setting. Reflow soldering is a key process in SMT production. Reasonable temperature curve setting is the key to ensure the quality of reflow soldering. Improper temperature curve will lead to incomplete welding, false soldering, component warping, excessive solder balls and other welding defects, which will affect the product quality.

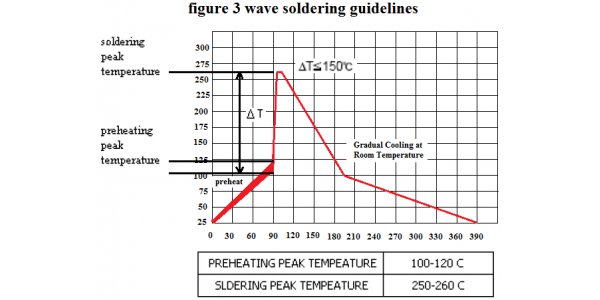

Wave soldering refers to the solder wave that the melted solder (lead tin alloy) is sprayed into the design requirements by electric pump or electromagnetic pump. It can also be formed by injecting nitrogen into the solder pool to make the printed circuit board with pre installed components pass through the solder wave to realize the mechanical and electrical connection between the component solder end or pin and the PCB pad. Depending on the wave geometry used by the machine, there are many wave soldering systems. Wave soldering process: insert the component into the corresponding element hole → pre apply flux → pre bake (temperature 90-1000c, length 1-1.2m) → wave soldering (220-2400c) → remove excess plug-in pins → check.

First difference between wave soldering and reflow soldering

Reflow soldering process is to realize the mechanical and electrical connection between the solder end of surface assembly components or pins and the PCB pad by remelting the paste solder pre allocated to the PCB pad.Wave soldering has a new welding process with the enhancement of people's awareness of environmental protection. In the past, tin lead alloy was used, but lead is a heavy metal, which has great harm to human body. So now there's the lead process. It uses tin silver copper alloy and special flux, and the requirement of welding temperature is higher, and higher preheating temperature is also required. A cooling zone workstation should be set up after PCB passes through the welding area. This is to prevent thermal shock, on the other hand, if there is ICT, it will affect the detection. Wave soldering can be basically interpreted as soldering larger and smaller components, which is different from reflow soldering. Reflow heating the boards and components is actually liquefying the original pastes, so as to connect the components and boards

1) Reflow soldering passes through preheating zone, reflow zone and cooling zone. In addition, wave soldering is suitable for manual plug-in board and spot glue board, and all components are required to be heat-resistant. Components with SMT solder paste can not be used on the wave surface. The board of SMT solder paste can only be reflow soldered, and wave soldering is not allowed.

2) Wave soldering is to dissolve the tin strip into liquid state through tin bath, and form wave by motor agitation, so that PCB and parts can be welded together, which is generally used in the welding of hand plug-in and SMT glue board. Reflow soldering is mainly used in SMT industry. It melts solder paste printed on PCB and solders parts through hot air or other heat radiation conduction.

3) Different process: spray flux first, then through preheating, welding and cooling zone.

Second difference between wave soldering and reflow soldering

Wave soldering is mainly used for welding plug-ins while reflow soldering is mainly used for SMD components.

1) Wave soldering is to dissolve the tin strip into liquid state through the tin bath, and use the motor to stir to form wave, so that PCB and parts are welded together, which is generally used in the welding of hand plug-in and SMT glue board. Reflow soldering is mainly used in SMT industry. It melts the solder paste printed on PCB and solders the parts through hot air or other thermal radiation conduction.

2) Different processes: spray flux before wave soldering, and then through preheating, welding and cooling zone. Reflow soldering passes through preheating zone, reflow zone and cooling zone. In addition, wave soldering is suitable for manual plug-in board and spot glue board, and all components are required to be heat-resistant. Components with SMT solder paste can not be found on the wave surface. The board of SMT solder paste can only be reflow soldered, and wave soldering is not allowed.