1) Cutting

Cutting is the first step in the mechanical operation of printed circuit board. The rough shape and outline can be given by cutting. The basic cutting method is suitable for all kinds of substrates, usually less than 2 mm thick. When the cutting board is more than 2 mm, the cutting edge will appear rough and irregular, so this method is generally not used.Laminate shear can be manual operation or electro mechanical operation, no matter which method has common characteristics in operation. The blade is rectangular, with an adjustable angle of about 7° at the bottom, and the cutting length can reach 1000 mm. The longitudinal angle between the two blades is usually between 1° and 1.5° and can be up to 4° when using epoxy glass substrate. The gap between the cutting edges of the two blades should be less than 0.25 mm.

The angle between the blades should be selected according to the thickness of the cutting material. The thicker the material, the greater the angle required. If the shear angle is too large or the gap between the two blades is too wide, the board will crack when cutting the paper substrate. However, for the epoxy glass substrate, because the material has a certain bending strength, even if there is no crack, the board will also deform. In order to keep the bottom edge clean during shearing, the material can be heated in the range of 30 - 100 ℃.

In order to avoid the inevitable displacement of the other plates in the cutting process, a spring must be pressed down. In addition, parallax can also lead to a tolerance of 0.30 0.5 rnrn, which should be reduced to the minimum. The accuracy can be improved by using corner markers. The shears are able to handle a wide range of sizes and provide accurate repeat sizes. Large machines can cut hundreds of kilograms of substrate per hour.

2) Sawing

Sawing is another way to cut the substrate. Although the dimensional tolerance of this method is similar to that of shear (0.3-0.5 rnrn), it is more desirable because the cutting edge is very smooth and neat.In the PCB manufacturing industry, the circular sawing machine with movable worktable is mostly used. The adjustable speed range of saw blade is 2000-6000r / rnin. But once the cutting speed is set, it cannot be changed. It is achieved by a heavy pulley with more than one V-belt.

The diameter of the high-speed moving steel blade is about 3000 rnrn. It can cut paper-based materials at the rate of 2000-3000r / rnin. There are about 1.2-1.5 teeth per 1 cm circumference. For epoxy glass substrate, use the blade with tungsten carbide blade. Diamond wheel cutting effect will be better, although it at the beginning of the investment, but because of its long service life and can improve the edge cutting effect, so it is very useful for future work.

While using the cutting machine, pay attention to the cutting force directly acting on the edge and check the firmness of the bearing. There should be no abnormal feeling when checking by hand. For safety reasons, the teeth should always be covered by protective devices. The mounting shaft and engine should be placed accurately. Also the gap between the serrated blade and the bracket should be minimized so that the board can have a good support for edge cutting. At the same time, the circular saw should be adjustable and the height range between blade and board should be 10-15mm. And blunt teeth and too rough teeth will make the cutting edge not smooth, it is better to replace it. If the cutting speed is wrong, the cutting edge will not be smooth. It should be adjusted properly. The thick material needs to choose a slow speed, while the thin material can be cut quickly. It should operate according to the speed given by the manufacturer. If the blade of the saw is very thin, a reinforcing pad can be added to reduce vibration.

3) Punching

When printed circuit board design has other shapes or irregular outline besides rectangle, using punching mould is a fast and economical method. The basic punching operation can be completed with a punch, and its cutting edge is neat while the effect is better than that of using a saw or a shearing machine. Sometimes, even drilling and punching can be carried out at the same time. However, when good edge effect or small tolerance is required, punching cannot meet the requirements. In the printed circuit board industry, punching is generally used to cut paper substrate, but rarely used to cut epoxy glass substrate. Punching can make the cutting tolerance of printed circuit board within ± (0.1 - 0.2 mm).

<1>Punching of paper substrate

Because the paper substrate is softer than the epoxy glass substrate, it is more suitable to be cut by punching. When using the punching tool to cut the paper substrate, the rebounds or bending of the material should be considered. Because the paper substrate often rebounds, the punching part is a little larger than the die. Therefore, the size of the mold should be selected according to the tolerance and the thickness of the substrate, which is slightly smaller than the printed circuit board to compensate for the excess size. As people have noticed, when punching, the mold is larger than the size of the hole, and when punching, the mold is smaller than the normal size.

For the circuit board with complex shape, it is better to use step-by-step tools, such as cutting the material one by one. With the die punching it one by one, the shape of the material gradually changes. In this way, through the first one or two steps, the hole is penetrated, and finally the other parts are punched. Punching and cutting after heating can improve the cutting effect of printed circuit board, such as heating the strip to 50-70'c and then punching. However, care must be taken not to overheat as this will reduce the expansion after cooling. In addition, attention should be paid to the thermal expansion of paper-based benzoic acid materials, because they exhibit different expansion properties in z-direction and y-direction.

<2> Punching of epoxy glass substrate

When the required shape of epoxy glass substrate cannot be produced by cutting or sawing, a special punching method can be used. Although this method is not popular, this method can only be used when the cutting edge or size requirements are not too strict. Because although the function is acceptable, the cutting edge does not look very neat. Because the rebounds performance of epoxy glass substrate is smaller than that of paper substrate, the tools for punching epoxy glass substrate should have a close cooperation between die and press. The punching of epoxy glass substrate should be carried out at room temperature. Because the epoxy glass substrate is hard and difficult to cut, the life of punch will be reduced, and it will be used up quickly. Good cutting effect can be obtained by using the punch with carbide tip.

4) Milling

Milling is usually used in PCB which requires neat cutting, smooth edge and high dimensional accuracy. The normal milling speed is in the range of 1000-3000r / min, and the linear or spiral tooth high-speed steel milling machine is usually used. However, for epoxy glass substrates, it is best to use carbonized pigeon tools because of their long life. In order to avoid delamination, the back of the printed circuit board must have a solid liner when milling. For detailed information on milling machines, tools and other operations, refer to the factory or store standard instructions for these equipment.

5) Grinding

In order to obtain better edge effect than cutting or sawing and achieve higher dimensional accuracy, especially when the printed circuit board has irregular outline, grinding method can be selected. When the dimension tolerance is ± (0.1-0.2mm), the cost is less than that of punching. Therefore, in some cases, the size beyond the punching can be trimmed in the subsequent grinding process to obtain a smooth cutting edge.

The multi axis machines used now make grinding very fast, and the investment and total cost of workers are less than that of punching. When the routing of a board is close to the edge, grinding may be the only way to obtain a satisfactory cutting quality.

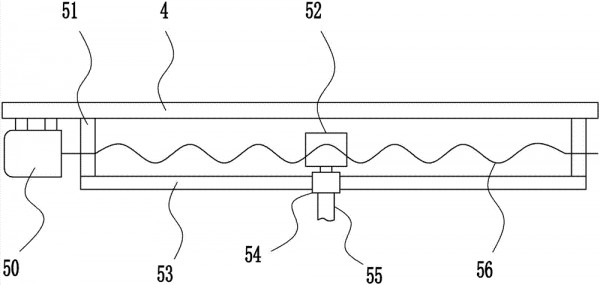

The basic mechanical operation process of grinding is similar to that of mirror cutting, but its cutting speed and feed speed are much faster. The plate moves along the vertical grinding surface with the reference of the grinding fixture. The grinding fixture is fixed on a bushing with the same center as the grinding tool according to the grinding needs. The position of PCB in the grinding fixture is determined by the alignment hole of the material. There are three kinds of grinding system, they are needle grinding system, tracking or recording needle grinding system and numerical control (NC) grinding system.