When removing and replacing electronic components, it is often necessary to remove excess solder from the pad. There are many ways to remove them, which need to be used according to the actual situation. Excess solder filling holes often occur on PCB boards. In general, plugging is the residual solder that occurs when an existing electronic component is un-welded and a PCB is removed. If there is residual solder on PCB, which method should be used to remove it? At this time, it is necessary to use hot air leveling technology.

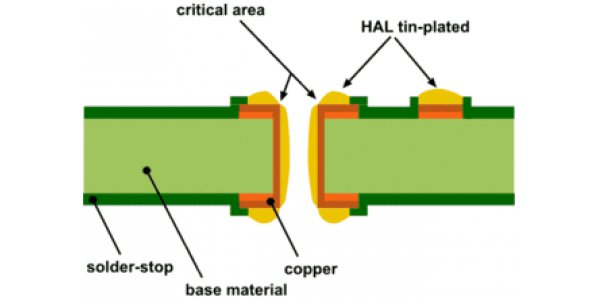

Hot air leveling is also called tin spraying. The process is: dip solder on the printed board, put it into the molten solder, and then pass between the two air knives. Use the hot compressed air in the air knife to blow off the excess solder on the printed board, and eliminate the excess solder in the metal hole, so as to obtain a bright, flat and even solder coating.

Compared with other processes, hot air leveling is relatively simple, although so, many programs and their coefficients need to be well controlled to produce high-quality PCB, otherwise, as long as there is a little problem, it may affect the overall quality of PCB. The procedures and coefficients to be noted are as follows:

1) Tinning time: when soldering, a layer of metal compound will be formed between the base copper and tin in the solder, and a layer of solder coating will be formed on the wire. The longer the immersion time is, the thicker the solder is, and the shorter the immersion time is, the half immersion phenomenon is easy to occur, resulting in partial tin surface whitening. In general, the tin dipping time is controlled at 2-4 seconds.

2) Bath temperature: the bath temperature needs to be controlled within a certain range. If it is too low, it is not enough to work. If it is too high, the substrate will be damaged and lead to the reaction between tin alloy and copper. Generally, the temperature is controlled at about 230-250 ℃.

3) Pressure of air knife: the function of air knife is to blow off the excess solder and guide through the metallized hole without reducing the hole diameter too much. Generally, the pressure of air knife is controlled as 0.3 -0.5 MPA.

4) Blowing time: the blowing time of the air knife mainly affects the coating thickness of the solder. The coating is thinner for a long time, and the coating in the hole is also thinner. If the time is short, irregular hole plugging will be produced. Generally, the blowing time of the air knife is 1-3 seconds.

5) Temperature of air knife: the temperature of air knife has certain influence on the appearance of the leveled solder coating. If the temperature is too low, the coating surface will be dark, and if it is too high, it will cause damage. The temperature of air knife is generally controlled between 300-400 ℃.

6) Angle of air knife: if the angle of air knife is too large, the hole will be blocked. If the angle is not adjusted properly, the thickness of solder on both sides of the board will be different, and the molten solder will be splashed. Generally, the front air knife is 3-50 ° and the rear air knife is 4-70 °.