Hot air leveling is also called tin spraying. Its working principle is to use hot air to remove excess solder from the surface and holes of the printed board, and the remaining solder is evenly covered on the pad and solder lines without resistance, and the surface is sealed.

The hot air leveling process is relatively simple, mainly including: plate laying (gold-plated plug protection tape) - hot air leveling pretreatment - hot air leveling - cleaning after hot air leveling - inspection. Although the hot air leveling process is simple, there are many process conditions to be mastered if you want to produce a good and qualified PCB by hot air leveling, such as solder temperature, air knife air temperature, air knife pressure, immersion welding time, lifting speed, etc. These conditions all have set values, but they should be changed according to the external conditions of the PCB and the requirements of the processing sheet, such as: board thickness, single side, double side and multi-layer boards with different board length. The conditions they adopt are different. Only when they are familiar with various process parameters, adjust the machine according to different types and requirements of PCB, patiently, carefully and reasonably, can the qualified PCB be leveled by hot air.

The process requirements and operation procedures of hot air leveling are all included in the process file. I have worked in hot air leveling for two or three years, although the time is not long, but I have some experience. For equipment, PCB quality and production process as follows:

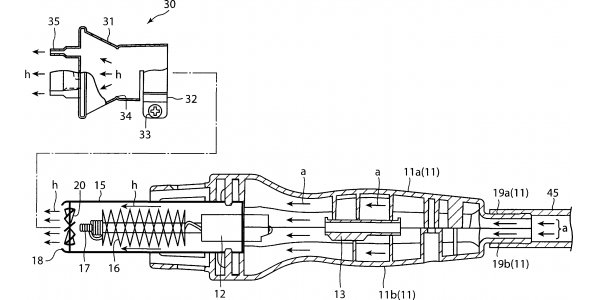

1) The phenomenon of residual liquid dripping from the air outlet of hot air leveling is that yellow liquid drips down from the air outlet of hot air leveling, which is mainly the flux inhaled by the air outlet during leveling. It accumulates in the exhaust duct for a long time and can't be discharged, so it drips around the air outlet. It drips everywhere, like the hot air duct, the air knife edge, and the protective cover on the air knife edge drips the most. Sometimes, it drips on the operator's head during work. On the work clothes, it drips the most residual liquid after the next shift closes the exhaust. This situation can be seen from many equipment in our room, For example, hot melting, which covers the equipment for a long time, may cause a lot of residual corrosion to the equipment. I think if there is a wire to drain the residual liquid, it may reduce or solve this situation. Several wires can be welded in the air outlet. The upper end of the wire is spirally welded in the air outlet, and the lower end is led into the trench or into the waste liquid tank. After welding, the residual liquid flows downward from the air outlet When flowing through the spiral wire, a large part of the residual liquid will flow down the spiral wire. The wire can weld several more wires, but the slope of the spiral pattern is larger, so that more residual liquid can be drained. And prevent the residual liquid from dripping after flowing through the wire.

2) The baffle plate at the hanging nail needs to be replaced. There is a hanging nail at the lower end of the hanging arm. Its function is to hang the printed circuit board. After the board is hung, it needs to be blocked by a baffle plate before it can enter the solder groove. The function of this baffle is to block the printed board, so that the printed board cannot fall off during hot air leveling. The baffle is fixed on the hanging arm by a lock pin, and the lock pin can rotate freely. However, it is because of the rotation of the baffle plate during operation that the friction between the baffle plate and the hanging arm is formed. After a long time, the card plate becomes thinner, and a lot of metal on the place covered by the card plate on the hanging arm also falls off. The gap between the baffle plate and the hanging arm becomes larger. After the gap becomes larger, part of the solder is hidden in the gap during the hot air leveling process. When rotating the baffle plate to take the PCB, this part of solder will drop on the PCB, which is likely to flow into the hole, causing blockage. After a long time of rotation, the lock pin of the baffle also becomes loose, so that the baffle cannot play a good role in blocking the printed board. As a result, many printed boards fall off into the welding groove in the work, resulting in unnecessary rework. I have been looking for maintenance personnel for many times to repair, but I can only tighten the lock nails temporarily. After a period of use, they start to loosen again, and they are more and more serious. I think there will always be friction problems through this method of fixing the lock nails. Other methods should be used. I think that the arm hanging system like the old hot air leveler is very feasible, and the baffle can be changed through the adjustment of air pressure loose and tight, which cannot only solve the problem that the baffle is not firm, but also solve the problem that the gap between the baffle and the hanging arm is too large and there is solder.

3) The gloves used in hot air leveling usually are canvas gloves. Put one pair of gloves into another pair of gloves and put them on the hands for work. After a little longer time, the flux will be immersed in the gloves. At this time, the heat insulation ability of the gloves will be greatly reduced. Moreover, the opponent will be hurt if the flux is immersed in the hands. After washing the gloves immersed in the flux It can be used again, but the effect is not good. Because the canvas becomes soft and the flux is immersed very quickly and in a large amount, can we make a glove by ourselves with leather or rubber and other materials, which has great heat insulation ability and the flux cannot be immersed. After work, we can clean the surface of the glove with water, so we do not need to use the canvas gloves, but also can save a little cost. There is another way , we can order a suitable rubber glove and put it into canvas gloves, so we can save one pair of two pairs of gloves. The key problem is that the size of this rubber glove should be appropriate, the heat insulation should be good, and the softness should be good. Now all kinds of rubber gloves in the warehouse do not suitable for these conditions.