Immersion Silver Features

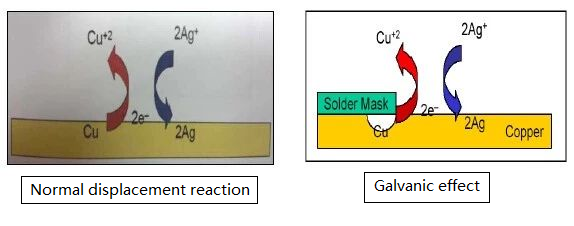

1) Galvanic effect

This problem must be traced back to the copper electroplating process. It is found that the case where the object is deep hole copper plating and blind hole copper plating with a high thickness-to-diameter ratio. If it can provide a more uniform copper thickness distribution, it will reduce this type of Galvanic effect phenomenon. Moreover, in the PCB manufacturing process, the stripping of metal resists (such as pure tin layer) and etching of copper, etc., once there is over-etching and side erosion, the plating solution and micro-etching solution may be hidden.

In fact, the biggest source of Galvanic effect is the green paint project, in which the side erosion and film relief caused by the green paint phenomenon are most likely to cause fine cracks. Where the green paint phenomenon can cause a positive residual foot instead of a negative side erosion, and after the green paint is completely hardened, this type of Javan's copper bite will be eliminated. As for the operation of copper electroplating, it is necessary to make the copper electroplating in the deep holes more even during the strong stirring. At this time, it is necessary to take the advantages of ultrasonic wave and strong current to stir to improve the mass transfer of the bath and the copper thickness. As for the process of immersion silver plating, it is necessary to strictly control the micro-etching bite rate of the front section. The smooth copper surface can also reduce the existence of fine cracks after green paint. Finally, there is no over strong copper bite reaction in the silver bath itself. The pH value is preferably neutral, and the plating rate should not be too fast. It is best to cut the thickness as thin as possible to optimize the silver crystal Only then can the anti-tarnishing function be completed.

2) Improvement of discoloration

The improvement method is to increase the plating density and reduce its porosity. The packaging products must be sealed with sulfur-free paper to isolate oxygen and sulfur in the air, thereby reducing the source of its discoloration. And the temperature of the environment in the storage area should not exceed 30 ℃, and the humidity must be less than 40% RH. It is best to adopt the advanced first-use policy to avoid problems caused by storage for too long.

3) Improvement of exposed copper on silver surface

The various processes before immersion silver plating need to be carefully controlled. For example, after micro-etching the copper surface, pay attention to the "water break" detection (Water Break refers to water repellency) and the observation of particularly bright copper spots, which all indicate that there may be a certain Some foreign objects. The clean copper surface with good micro-etching should be kept upright within 40 seconds without water breakage. The connection equipment should also be regularly maintained to maintain the uniformity of its water-based, so that a more uniform silver plating layer can be obtained. During the operation, the DOE experiment plan must be continuously tested on the copper plating time, liquid temperature, stirring, and pore size to obtain the best quality silver plating, and for thick plates with deep holes and HDI micro blind holes The immersion silver plating process of the board can also use the external assistance of ultrasound and strong current device to improve the distribution of the silver layer. The extra vigorous stirring of these baths can indeed improve the ability of wetting and exchange of the liquid in the deep and blind holes, which is of great help to the entire wet process.

4) Improvement of ion pollution on the board surface

If the ion concentration of the immersion silver plating bath can be reduced without hindering the quality of the plating layer, the ions brought out and adhered to the surface of the plate can be naturally reduced. After cleaning after immersion plating, it must be rinsed with pure water for more than 1 minute before drying to reduce the adhesion of ions. Moreover, the cleanliness of the finished board should also be regularly checked to ensure that the amount of residual ions on the board surface is minimized to meet the industry specifications. Records of all tests conducted should be kept for future use.

5) Improvement of solder joint micro-holes

Interface micro-holes are still the most difficult shortcomings to be improved in immersion silver plating, because the origin is still not clear, even though, some related reasons have been determined. Therefore, in order to minimize the occurrence of related factors, of course, the occurrence of downstream welding micro-holes can also be reduced.

Among the relevant factors, the thickness of the silver layer is the most relevant factor, and the thickness of the silver layer must be reduced as much as possible. Secondly, the micro-etching of the pretreatment should not make the copper surface too rough, and the uniformity of the silver thickness distribution is also one of the key points. As for the content of organic matter in the silver layer, it may be inversely known from the purity analysis of the multi-point sampling silver layer, in which the content of pure silver cannot be lower than the atomic ratio of 90%.

For the five common shortcomings of immersion silver plating, some prevention and improvement methods have been found, which can provide PCB manufacturers to solve problems and improve yield.

Immersion silver process flow

1)Hang up →Ultrasonic Cleaning →Water Wash X2 (Reverse Drift) → Alkaline Etching → Water Wash X2 (Reverse Drift) → Immersion Zinc → Water Wash X2 (Reverse Drift) → Immersion Zinc 1

2)Water Wash X3 (Reverse Drift) → Immersion Zinc 2 →Water Wash X2(Reverse Drift) → Pre-plated Copper → Water Wash X3 (Reverse Drift)→ Active → Water Wash X3 (Reverse Drift)→ Coked copper → Water Wash X3(Reverse Drift)→Active → Pre-silvered → Silvered → Recycle X2 → Pure water wash → Anti-silver Discoloration → Hot pure water x3 → Hang Down