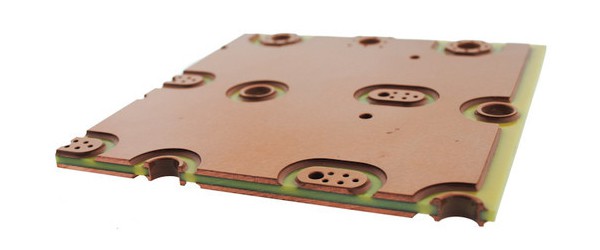

PCB Design Guidelines - HeavyEXTREME Copper Board

Posted: May 14, 2022

By: Bonnie

For a PCB circuit board with a copper thickness of more than 2 ounces, due to the copper thickness, the design specifications of the circuit board are different from the general circuit board. The following is the document inspection specification for thick copper plates.

B: The distance between general adjacent wires must be at least 0.25mm

C: The copper foil around the fixing hole should be no less than 0.4mm away from the edge of the hole, and there should be no thin wires at a distance of 1.5mm from the edge of the hole

D: The distance between the wire and the edge of the printed board is generally not less than 3mm, especially not less than 1.5mm, but the wiring width must not be less than 1.5mm, the ground wire should not be less than 0.5mm

E: Whether to consider low-density wiring design

F: Whether the conductor is routed according to the shortest route and whether there is no sharp angle at the turning point

G: Whether the joint between the wire and the pad is smoothed into a slope

B: For ICs with a pitch of 1.78mm, the pitch of the connection (pad) should not be less than 0.3mm

C: Whether the minimum diameter of the circular pad meets the standard

D: For the components inserted after wave soldering, is the solder pad open for tin bath

E: There must be no connection between the pads and between the pads and the exposed copper foil

F: Whether the pads of the switching transformer and harmonic current suppressor are removed, whether the empty pads are removed to prevent wrong insertion

G: Whether the filter inductance of the AC input circuit, the switching transformer, inverter transformer, high-power resistor, high-power damping or rectifier rectifier diode (non-plastic package), rectifier large electrolytic capacitor pad, whether it is reinforced with rivets

H: The number of rivet pads for multi-pin component pads should generally not be less than 1/2 of the pin count of the component

I: Whether the design requirements of the rivet hole pad meet the standard. The 1.8mm diameter rivet pad is 4.5mm. If it is not satisfied, a 4.0mm pad is needed, and a drop of tin is added to strengthen it. The rivet pad of 2.4mm hole diameter is 5.5mm. If it is not satisfied, 5.0mm pad should be used. At the same time, a drop-shaped tin can be added for reinforcement

J: With the positioning hole of the printed board as the center, no rivet pad is designed within a radius of 7mm, and the rivet pad is not designed if the distance between adjacent holes is less than 6mm

H: Whether the key components are reinforced with rivets, and whether the key component pads are added with water droplets on the tin

B: Whether there are heat dissipation measures for high-power components

C: High-power heating device and large-volume electrolytic capacitor, the distance should be greater than 5mm

D: Whether the heat conduction facilities of the device are considered

E: Is the fixing and location of the radiator suitable

F: The heating device should have a proper amount of heat dissipation holes under and around the printed board, and its diameter is generally not more than 4mm

G: Large area copper foil is susceptible to heat, causing copper foil to expand. If the area exceeds 15mm in diameter, the conductive layer must have a conductive window

B: Whether the layout of high-power devices is even, whether the direction of heat dissipation is considered, and the strength of the board

C: Whether the fixed device is added for large-quality devices

D: Whether the insulation measures of the device are considered

E: Whether the arrangement of components is horizontal or vertical

F: The radiator should not touch the surrounding components

G: Whether the design of the pad position is evenly distributed

H: Are there any nail bottom components and flying leads

I: The heat sink is installed, whether it conforms to the direction of heat dissipation, and whether the existing heat sink is used as much as possible to reduce the possibility of making a new heat sink

J: The maximum PCB board length, whether it is not greater than 600mm, and the width is not greater than 360mm

K: Are there grounding lugs installed at the fixed holes in cold place, is the grounding lug sufficient

L: Whether there are more than three global Mark points on the copper foil surface of the board, whether the increased position meets the process requirements and affects the safety distance

M: Whether the arrangement of vertical electrical plug components can ensure that the outer edge distance between pieces is more than 1mm

N: Whether there are solder pads and copper foil on the edge of the printed board, which makes assembly difficult

O: Whether the vertical plate considers the fixing method

P: Do the components fixed on the heat sink have space that can be removed without removing the radiator

Q: Are there tall and dense components around the socket, or the sharp corners of the radiator

R: Whether the input and output socket placement position meets the convenience of connecting with other boards of the whole machine

S: Whether the chip components are placed perpendicular to the long side of the board to avoid breakage or damage caused by deformation

T: Whether the plug-in IC and the patch IC are placed horizontally, consistent with the direction of wave soldering, which conforms to the wave soldering process. When the IC is over-wave soldering, is there a tin-stealing pad designed at an appropriate position to avoid continuous soldering of the over-heating pad

U: When placing all chip components, should you consider avoiding the shadow effect

V: Fixed components, whether there is interference with the screws of the heat sink and the components on the board

B: The reserved position of the supporting bar should not be within the bending range of the component lead

C: Due to structural limitations, it is not suitable for wave soldering components. It is necessary to install a tin bath in a position opposite to the wave direction, and the groove width is 0.7mm

D: The direction of wave soldering must be clearly marked on the upper and lower sides of the board

E: Try not to lay out components with a space size like horizontal plug-in wires that extend beyond the edge of the board

F: The secondary solder resist layer should be coated around the bends of the leads of the electrical plug components, around the transistors, ICs and the pads of the socket pins

1. Wire design specifications for circuit board design

A: The minimum width of the wire of the circuit board is not less than 0.3mmB: The distance between general adjacent wires must be at least 0.25mm

C: The copper foil around the fixing hole should be no less than 0.4mm away from the edge of the hole, and there should be no thin wires at a distance of 1.5mm from the edge of the hole

D: The distance between the wire and the edge of the printed board is generally not less than 3mm, especially not less than 1.5mm, but the wiring width must not be less than 1.5mm, the ground wire should not be less than 0.5mm

E: Whether to consider low-density wiring design

F: Whether the conductor is routed according to the shortest route and whether there is no sharp angle at the turning point

G: Whether the joint between the wire and the pad is smoothed into a slope

H: In the power circuit, the distance between the adjacent wires between hot and cold ground should not be less than 6mm

2. Pad design specifications for circuit board design

A: The distance between the pad of the inserted component and the edge of the printed board is generally not less than 7mm, especially not less than 3.5mm, and the distance between the pad of the mounted component and the edge should not be less than 5mm. For the edge of the board where the process side is to be left, regardless of the entity and pad of the inserted component or the mounted component, it should not be less than 5mm from the edge of the boardB: For ICs with a pitch of 1.78mm, the pitch of the connection (pad) should not be less than 0.3mm

C: Whether the minimum diameter of the circular pad meets the standard

D: For the components inserted after wave soldering, is the solder pad open for tin bath

E: There must be no connection between the pads and between the pads and the exposed copper foil

F: Whether the pads of the switching transformer and harmonic current suppressor are removed, whether the empty pads are removed to prevent wrong insertion

G: Whether the filter inductance of the AC input circuit, the switching transformer, inverter transformer, high-power resistor, high-power damping or rectifier rectifier diode (non-plastic package), rectifier large electrolytic capacitor pad, whether it is reinforced with rivets

H: The number of rivet pads for multi-pin component pads should generally not be less than 1/2 of the pin count of the component

I: Whether the design requirements of the rivet hole pad meet the standard. The 1.8mm diameter rivet pad is 4.5mm. If it is not satisfied, a 4.0mm pad is needed, and a drop of tin is added to strengthen it. The rivet pad of 2.4mm hole diameter is 5.5mm. If it is not satisfied, 5.0mm pad should be used. At the same time, a drop-shaped tin can be added for reinforcement

J: With the positioning hole of the printed board as the center, no rivet pad is designed within a radius of 7mm, and the rivet pad is not designed if the distance between adjacent holes is less than 6mm

H: Whether the key components are reinforced with rivets, and whether the key component pads are added with water droplets on the tin

3. Thermal design specification for circuit board design

A: Whether the thermal element is far away from the heat sinkB: Whether there are heat dissipation measures for high-power components

C: High-power heating device and large-volume electrolytic capacitor, the distance should be greater than 5mm

D: Whether the heat conduction facilities of the device are considered

E: Is the fixing and location of the radiator suitable

F: The heating device should have a proper amount of heat dissipation holes under and around the printed board, and its diameter is generally not more than 4mm

G: Large area copper foil is susceptible to heat, causing copper foil to expand. If the area exceeds 15mm in diameter, the conductive layer must have a conductive window

4. Layout design specifications for circuit board design

A: Is it possible to complete the production through the simplest assembly processB: Whether the layout of high-power devices is even, whether the direction of heat dissipation is considered, and the strength of the board

C: Whether the fixed device is added for large-quality devices

D: Whether the insulation measures of the device are considered

E: Whether the arrangement of components is horizontal or vertical

F: The radiator should not touch the surrounding components

G: Whether the design of the pad position is evenly distributed

H: Are there any nail bottom components and flying leads

I: The heat sink is installed, whether it conforms to the direction of heat dissipation, and whether the existing heat sink is used as much as possible to reduce the possibility of making a new heat sink

J: The maximum PCB board length, whether it is not greater than 600mm, and the width is not greater than 360mm

K: Are there grounding lugs installed at the fixed holes in cold place, is the grounding lug sufficient

L: Whether there are more than three global Mark points on the copper foil surface of the board, whether the increased position meets the process requirements and affects the safety distance

M: Whether the arrangement of vertical electrical plug components can ensure that the outer edge distance between pieces is more than 1mm

N: Whether there are solder pads and copper foil on the edge of the printed board, which makes assembly difficult

O: Whether the vertical plate considers the fixing method

P: Do the components fixed on the heat sink have space that can be removed without removing the radiator

Q: Are there tall and dense components around the socket, or the sharp corners of the radiator

R: Whether the input and output socket placement position meets the convenience of connecting with other boards of the whole machine

S: Whether the chip components are placed perpendicular to the long side of the board to avoid breakage or damage caused by deformation

T: Whether the plug-in IC and the patch IC are placed horizontally, consistent with the direction of wave soldering, which conforms to the wave soldering process. When the IC is over-wave soldering, is there a tin-stealing pad designed at an appropriate position to avoid continuous soldering of the over-heating pad

U: When placing all chip components, should you consider avoiding the shadow effect

V: Fixed components, whether there is interference with the screws of the heat sink and the components on the board

5. Welding design specification for circuit board design

A: Is the PCB board wider than 180mm or longer than 320mm wave soldered. Is there a reserved support bar position of 3mm in the middle.B: The reserved position of the supporting bar should not be within the bending range of the component lead

C: Due to structural limitations, it is not suitable for wave soldering components. It is necessary to install a tin bath in a position opposite to the wave direction, and the groove width is 0.7mm

D: The direction of wave soldering must be clearly marked on the upper and lower sides of the board

E: Try not to lay out components with a space size like horizontal plug-in wires that extend beyond the edge of the board

F: The secondary solder resist layer should be coated around the bends of the leads of the electrical plug components, around the transistors, ICs and the pads of the socket pins

G: Large area copper foil is susceptible to heat and causes copper foil expansion. Therefore, the area of the area exceeding 15mm in diameter, the conductive layer needs to open a conductive window or grid.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

5

)

5

617

1

Share to: