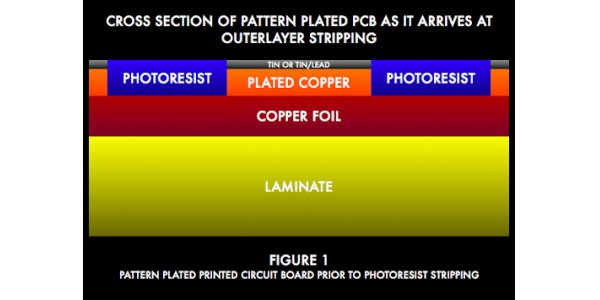

The etching process flow is: stripping film → line etching → stripping tin and lead.

1. Stripping

In the PCB process, two steps will be used for stripping the film. One is the D/F stripping after the inner layer is etched, and the other is the D/F stripping before the outer layer is etched (if the outer layer is made as a negative film process). The stripping of D/F is a simple and simple process, and generally uses connected horizontal equipment. The chemical liquid used is mostly NaOH or KOH concentration in the range of 1-3% by weight.

1) The dry film after hardening is partially dissolved under this solution, and partially peeled into flakes. To maintain the effect of the chemical solution and the complete washing after washing, the efficiency of the filtration system is very important.

2) Some devices are designed with light brushing or ultrasonic agitation to ensure the completeness of the film, especially after the outer layer is etched. The dry film that is slightly stuck by the secondary copper on the side of the circuit must be completely removed to avoid affecting the quality of the circuit . There are also BCS added to the solution to help dissolve, but it is against the environment and harmful to physics.

3)There are literatures that K (potassium) will attack tin, so the selection of the stripping solution before etching the outer circuit must be carefully evaluated. The film stripping solution is alkaline, so it is very important to wash thoroughly or not. After the film stripping of the inner layer is neutralized by pickling, there are also anti-copper surface oxidation and oxidation treatment.

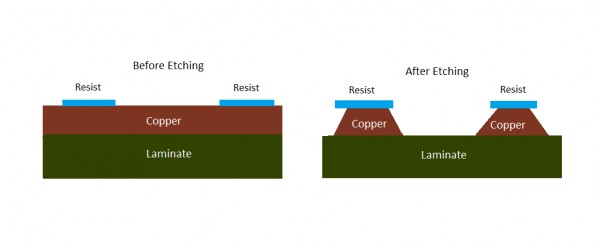

2. Line etching

1)Copper etching mechanism

<1> In alkaline environment solution, copper ions are very easy to form the precipitation of copper hydroxide. It is necessary to add enough ammonia water to generate the wrong ion group of ammonia copper, which can inhibit the occurrence of precipitation and at the same time make the original amount of copper And the copper that continues to dissolve forms a very stable ammonium copper ion in the liquid. This bivalent ammonium copper ion can also be used as an oxidant to oxidize and dissolve zero-valent metal copper, but there will be a monovalent in the redox reaction process and cuprous ions appear.

That is, the solubility of the intermediate cuprous ions in this reaction is very poor, and it must be assisted by ammonia water, ammonia ions and a large amount of oxygen in the air to continue to oxidize into soluble divalent copper ions, and then become an oxidizing agent for copper etching. Continue to etch copper until it is too much and slows down. Therefore, in addition to removing the ammonia odor, the exhaust air of the general etching machine can also supply fresh air to accelerate the copper etching.

<2> In order to make the above copper etching reaction proceed more quickly, more additives are added to the etching solution, for example:

A. Accelerator can promote the above-mentioned oxidation reaction more quickly and prevent the precipitation of cuprous ions.

B. Banking agent reduces side erosion.

C. Suppressor suppresses the scattering of ammonia at high temperature, inhibits the precipitation of copper and accelerates the oxidation reaction of copper etching.

2) Equipment

<1> In order to increase the erosion rate, it is necessary to increase the temperature to above 48 ℃, so there will be a lot of ammonia odor diffused and proper ventilation is required. However, when the amount of ventilation is too strong, it will also draw a lot of useful ammonia. If it is uneconomical, an appropriate throttle valve can be added in the exhaust pipe for control

<2>The etching quality is often limited by the pudding, (because the fresh liquid is blocked by the water, which cannot be effectively reacted with the copper surface, it is called the pool effect) This is why the front part of the board often has an over etch phenomenon. Therefore, the device design has the following considerations:

A. The thinner lines of the board face down, and the thicker lines face up.

B. The upper and lower nozzle liquid pressure adjustment is used as compensation, and the difference is adjusted according to the actual operation results.

C. The advanced etching machine can control the time when the board enters the etching section, the previous groups of nozzles will stop spraying for a few seconds.

D. There are also vertical etching methods designed to solve the problem of unevenness on both sides, but domestic use is rare.

3) Supplementary control

Automatic replenishment The replenishing solution is ammonia, usually with a very sensitive specific gravity, and it senses the temperature at that time (due to the difference in specific gravity at different temperatures), sets the upper and lower limits, and starts adding ammonia when it exceeds the upper limit, and stops when it is below the lower limit. At this time, the position of the detection point and the position of the nozzle for adding ammonia are very important, so as to avoid wasting the cost of adding too much ammonia due to delay detection (because it will overflow)

4) Daily maintenance of equipment

<1> No sludge (light blue monovalent copper sludge) is produced in the etching solution, so the composition control is very important-especially PH, too high or too low may cause it.

<2> Keep the nozzle from being blocked at all times. (The filtration system should be kept in good condition)

<3>The specific gravity addition system should be checked regularly.

3. Stripping tin (or lead)

Regardless of pure tin or tin-lead layers of various composition ratios, the purpose of the plating is only for anti-etching, so after etching, they must be stripped, so this step of stripping tin (lead) is only processing, and no added value is generated. . But the following points still need to pay special attention, otherwise the cost increase is the second, and it is difficult to complete the outer circuit but cause problems here.

1) Generally, the tin stripping (lead) liquid is directly supplied by the supplier. There are a variety of formulations with two-liquid type and single-liquid type. The stripping methods include semi-soluble and fully soluble types. The solution consists of fluorine/H2O2 , HNO3/H2O2 and other formulas.

2) Regardless of the recipe, there are the following potential problems in the operation:

A. Attack the surface of copper

B. The process after stripping not fully affected.

C. Waste liquid treatment

Thus, the step of stripping tin (lead) must rely on good equipment design, the thickness control of tin (lead) plating in the pre-process and the management of the efficacy of the chemical solution to obtain stable quality. After the outer layer is completed, 100% inspection work is carried out.

Basis for judging the etching condition includes edge, side erosion, etching coefficient factor, over eclipse, etching surface finish and the clearness of the line spacing. With the miniaturization of electronic products, the wiring of the circuit board is going to the direction of fine circuit, high density, and small aperture, which puts higher requirements on the etching process.