SMT is Surface Mount Technology which is the most popular technology and process in the electronic assembly industry. It is a printed circuit board assembly technology that mounts leadless or short lead surface mount components (SMC/SMD) on the surface of the printed circuit board, and then solders and assembles them by reflow soldering or DIP soldering.

More resources:

PCBA Testing about AOI, FCT, AXI, ICT

8 PCB Assembly Testing - An Overview of SMT Test

SMT Test – The Key to Guarantee PCB functional

Why need SMT Testing?

1.Testing in SMT processing is a very important method to ensure the quality of PCBA. The main testing methods include manual visual, solder paste thickness gauge inspection, automatic optical inspection, X-ray inspection, online test, flying probe test, etc. Due to the different inspection contents and characteristics of each process, the inspection methods used in each process are also different. Differently, among the inspection methods of SMT processing, manual visual inspection, automatic optical inspection, and X-ray inspection are the three most commonly used methods in SMT assembly process testing.

2. Moreover, SMT processing is a relatively complex process, and the requirements for technicians are very strict, and even experienced technicians may inevitably encounter problems. In this case, we need to keep testing, using relevant tools and equipment to carry out repeated testing. Make sure the product quality is no problem.

3. In order to detect defects and faults in time and repair them, various SMT testing techniques need to be used for detection in the production process, so that the quality of PCBA can be guaranteed.

AiPCBA has advanced testing equipment, all-around control of the production process, and quality "zero" defect.

Here learn more about AiPCBA SMT service.

There are 3 common test methods of SMT that are used in testing process

1. Manual visual inspection (MVI): This testing method requires little investment and does not require test program development, but is slow and highly subjective, requiring intuitive visual inspection of the tested area. In fact, this is an inspection method that relies entirely on experience, and the requirements for technicians are relatively high. Due to the lack of visual inspection, it is rarely used as the main welding quality inspection method on the current SMT processing production line, and most of them are used for rework.

2. Automatic optical inspection (AOI): With the reduction of the package size of the SMD components and the increase in the surface mounting density of the printed circuit board, the SMT testing is becoming more and more difficult, and the manual visual inspection is not enough. Therefore, it is more and more important to use motion inspection.

(1) AOI adopts an advanced vision system, new light supply method, high magnification, and complex processing method, which can obtain a high defect capture rate at high test speed from the surface. This testing method is mainly used on the production line, and it can be used in many parts of the production line. Of course, inspection is mainly used for the operation of various defects.

(2) We can put the equipment in a place where defects are easy to occur in advance so that we can use AOI to find and deal with problems in time. If some parts are missing or there are redundant relevant parts, they need to be dealt with in time.

(3) The position of AOI on the SMT production line. There are usually three positions of AOI equipment on the SMT production line. The first is the AOI that is placed after solder paste printing to detect solder paste failures, which is called post-screen printing AOI. The second AOI is placed after the surface mounting to detect the device placement failure, which is called the post-mounting AOI. The third AOI is placed after reflow soldering to detect device placement and soldering faults at the same time, which is called post-reflow soldering AOI.

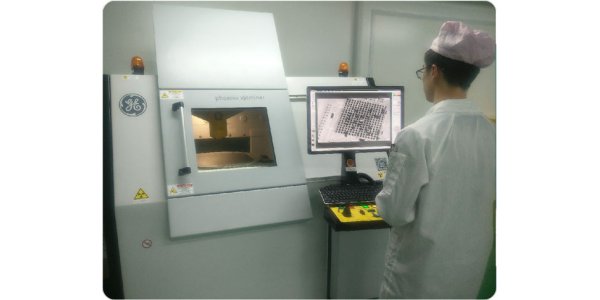

3. X-ray inspection: In smt processing: Because many high-precision PCBA boards have a large number of BGA and IC chips, the core components of this package cannot directly see the internal welding status from the surface after welding. Therefore, the PCBA manufacturer must be equipped with relevant testing equipment. The testing equipment for this type of welding here is mainly X-ray.

X-ray is through the transmitter in the machine to emit high-energy electrons to generate X-rays for sample penetration imaging. Since the density of each structure in the sample is different, the image presented when an X-ray penetrates different objects will be different. There are differences in black and white grayscale, which in turn show the location and morphology of defects in the sample. X-ray inspection is a non-destructive sample analysis, and other tests can be performed later.

X-ray inspection can be applied in:

(1) Observation of internal defects of IC packaging parts (broken traces, holes and cracks, etc.)

(2) Observation of the welding condition of the assembled printed circuit board ( missing solder, solder ball, solder bridge, etc.)

(3) Analysis of the porosity ratio in the welding point.

(4) Observation of positive, side and oblique angles of various materials.

(5) Observation of filling condition in porous material.

SMT Testing in AiPCBA

We have created a new and authoritative laboratory. Our laboratory assists clients to avoid manufacturing risks and supply chain risks in the product design and development stages. Actively help customers to solve the potential risks of problems from the source, and assist customers to solve problems such as product reliability. Provide better services for the electronics industry.

Check the SMT testing equipment in AiPCBA

|

Item |

Equipment Name |

Equipment Capability |

|

1 |

SPI Sinic - TEK |

100% 3D inspection of solder paste |

|

2 |

Smart First Article Checker- Bluiris |

SMT intelligent anti-error test |

|

3 |

AOI HOLLY |

100% machine mounting and solder inspection |

|

4 |

3D X-Ray |

3D all-round detection, with CT function |

Get Instant Quote in AiPCBA

PCB quote: In our online PCB quotation system , you only need to upload the Gerber file and fill in the PCB specifications, you can easily get a quotation within 10 seconds. At the same time, our quotation page is also equipped with the function of an online Gerber 3D Preview. you can upload a Gerber file and have a 360-degree view of your PCB design.

BOM quote: AiPCBA's self-developed BOM quotation system can identify component information within 30 seconds, and analyze and quote market prices. And our BOM quotation system does not have strict requirements on the BOM format, all of which are based on the development of our strong R&D team, and play an extremely important role in our thousands of BOM price confirmations.

PCB Assembly Quote: Based on AiPCBA's PCB and BOM online quote system, we have also developed the calculation formula for assembly costs accordingly and combined these three quotation systems to form our complete one-stop PCBA quotation. As long as you upload the Gerber file and BOM list, our system will give you a complete PCBA quotation within 30 seconds.

AiPCBA also accepts Requests for a quotation by email, we are glad to receive your attachments (Gerber files, BOM list, etc. ) Pls feel free to contact us at sales@aipcba.com.

More resources:

PCBA Testing about AOI, FCT, AXI, ICT

8 PCB Assembly Testing - An Overview of SMT Test

SMT Test – The Key to Guarantee PCB functional