Stripping

Because of the wide range of PCB technology, the production process is more complex, from simple machining to complex machining, there are common chemical reactions, photo-chemistry, electron-chemistry, Thermos-chemistry and other processes, and then to CAD CAM.

PCB striping strength is mainly used to measure the performance of adhesive. Generally speaking, the thicker the adhesive thickness, the better the striping strength. But this is not true, because the formula and structure of different manufacturers are different. If the molecular structure of the adhesive is very small, the bonding area between the adhesive and copper foil will increase. As a result, the bond strength is improved and the striping strength is improved. In current material manufacturers, this method can be used to improve the striping strength and reduce the adhesive thickness. In addition, the blackening process of copper foil itself and the composition of blackening layer will also affect the adhesion between adhesive and copper foil. Therefore, in order to improve the flexibility performance and striping strength of PCB, it is necessary to consider both material selection and production process control. For flexibility, we want to choose thinner materials, which is restricted by the strength and cost of striping, which may be a contradiction in PCB industry. The trend of electronic products is smaller, lighter and more convenient, which makes PCB require more layers, thinner materials and better performance.

The stripping strength of electrolytic copper foil is tested by hy-0580 stripping tester with recording instrument whose indication error is less than 1%. The failure load of the sample should be between 15% and 85% of the indication range of the tester. The striping testing machine should be equipped with a suitable oil bath, the temperature range of which is adjustable from room temperature to 300'c, and the temperature control accuracy is ± 2%. The copper foil was pressed into a copper clad laminate, and five samples with length of (75 ± 1) mm, width of (50 ± 1) mm, thickness of the original plate and neat edge were cut from the copper clad laminate. The standard figure is printed to make the strip width of copper foil strip is (3 ± 0.2) mm, the distance between two test strips is 10 mm, and each sample has 4 strips for peel strength test. When the nominal thickness of copper foil is less than 35 μ m, the thickness of copper foil can be increased by depositing copper before etching the standard test pattern, so as to avoid breaking of copper anchor during striping. However, the thickness of copper anchor after deposition shall not exceed 38 μ M. At the same time, the nominal thickness of the original copper should be stated in the test report.

The copper foil at one end of the sample is stripped about 10 mm from the substrate, and then the sample is clamped on the sample rack of striping machine, and the stripped copper foil is clamped with the sample clamp. When clamping the sample, the copper cylinder should be perpendicular to the substrate, and the whole width of the stripped copper foil should be clamped. Start the striping machine and apply tension evenly. The direction of tension is perpendicular to the plane of the substrate. The allowable deviation is ± 5 ° so that the copper is stripped at a constant speed of (50 ± 5) mm / min. Record the minimum peeling force and minimum load required per unit width during the stripping length not less than 25 mm as the striping strength, expressed in Newtons per millimeter. A layer of rigid plate can be pasted on the back of the thin plate which is easy to bend before the test, so as to avoid the bending of the sample during the test.

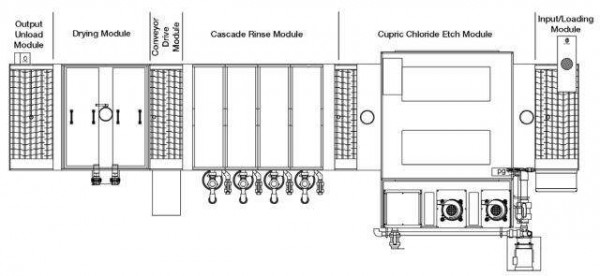

Etching

The etching methods can be divided into dipping, splash, rotary and spray. The operator must have a full understanding of the maintenance and control adjustment of the etching machine, so as to eliminate the problem. There are four general points for attention:

(1) Ventilation speed: generally keep a little negative pressure as moderate, so as not to cause a large amount of ammonia gas escaping, which is harmful to the health of the operators, and can maintain pH within a certain range, and there is an appropriate amount of air into the spraying area to provide oxygen for copper oxide oxidation and maintain the normal reaction. If the air is too much, the free ammonia concentration will be reduced quickly, and the pH value will be reduced, the etching rate will be slowed down, and the etching energy will be reduced. If there is insufficient ventilation, ammonia will escape from the machine, the etching solution will be anoxic, and the reduction of Cu2 + will slow down the etching rate.

(2) Add discharge system: discharge first, then discharge, and discharge at the same time. Part of the system is discharged from the cleaning tank (reduce the copper content in the cleaning waste water. The effect is different. For the etching of fine circuit, how to keep the parameters of etching solution in the specified range when discharging. When the outdoor temperature is very cold in winter, it is better to maintain the liquid temperature above 10 ° C. on the one hand, ammonium chloride does not crystallize, on the other hand, the bath liquid temperature will not change greatly, and the circuit board factory will control it well in general.

(3) Nozzle and spraying pressure: the upper and lower pressure should be adjusted properly, and the angle of nozzle should be tested to determine the best spraying pressure.

(4) Transport rate: the adjustment depends on pH, copper content and real specific gravity from time to time. Generally, 99% of copper has been etched through 3M spraying area. Fine line setting of fine circuits, so-called product fine lines, usually refers to circuits with line width and line space not greater than 5MIL.