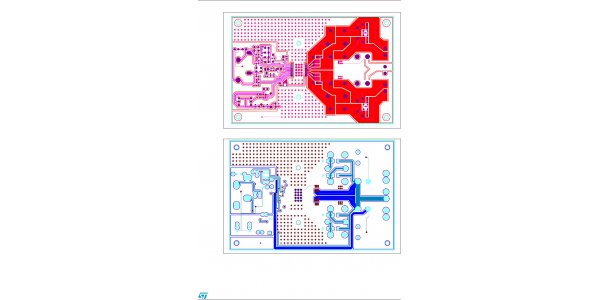

1. On the premise of ensuring the electrical performance, the components shall be placed on the grid in parallel or vertical arrangement for tidiness and beauty. In general, the components are not allowed to overlap; the arrangement of components shall be compact, and the components shall be evenly distributed and densely distributed in the whole layout.

2. In general, all components should be arranged on the same side of the circuit board. Only when the top components are too dense, can some devices with limited height and low heat output, such as chip resistor, chip capacitor and chip IC, be placed in the lower layer.

3. Generally, the distance from the edge of the circuit board shall not be less than 2mm. The best shape of the circuit board is rectangular, and the length width ratio is 3:2 or 4:3. When the surface size of the circuit board is greater than 200 mm by 150 mm, the mechanical strength that the circuit board can bear shall be considered.

4. The minimum distance between adjacent pad patterns of different components on the circuit board should be more than 1 mm.

In the layout design of PCB, the unit of circuit board should be analyzed, and the layout design should be carried out according to the function. When all components of the circuit are arranged, the following principles should be followed:

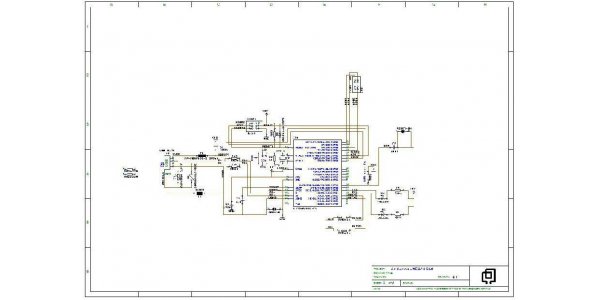

1. The position of each functional circuit unit is arranged according to the circuit flow, so that the layout is convenient for the signal flow, and the signal is as consistent as possible.

2. With the core components of each functional unit as the center, layout around it. Components should be evenly, integrally and compactly arranged on PCB to minimize and shorten lead wires and connections between components.

3. The distributed parameters between components should be considered when the circuit works at high frequency. In general, the components should be arranged in parallel as far as possible, which is not only beautiful, but also easy to install and mass produce. Special components and layout design in PCB, special components refer to the key components in high frequency part, core components in the circuit, components susceptible to interference, components with high voltage, components with high heat, and some components with different characteristics. The location of these special components needs to be carefully analyzed to make the layout meet the requirements of circuit function and production. Improper placement of them may lead to circuit compatibility problems and signal integrity problems, which will lead to the failure of PCB design. In the design of how to place special components, first consider the size of PCB. When the PCB size is too large, the printing line is long, the impedance is increased, the anti-drying ability is reduced, and the cost is also increased; if the PCB size is too small, the heat dissipation is not good, and the adjacent lines are easy to be interfered. After the size of PCB is determined, the square position of special components is determined. Finally, according to the function unit, all the components of the circuit are arranged.

The location of special components shall be arranged in accordance with the following principles:

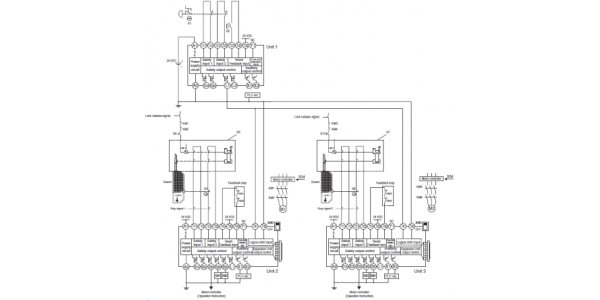

1. Some components or wires may have high potential difference, so their distance should be increased to avoid accidental short circuit caused by discharge. High voltage components should be placed as far as possible out of reach of hands.

2. As far as possible to shorten the connection between high-frequency components, try to reduce their distribution parameters and mutual electromagnetic interference. Components susceptible to interference should not be too close to each other, input and output should be as far away as possible.

3. Components weighing more than 15g can be fixed by bracket and then welded. Those heavy and hot components should not be placed on the circuit board, but on the bottom plate of the main box, and the heat dissipation should be considered. Thermal components should be far away from heating components.

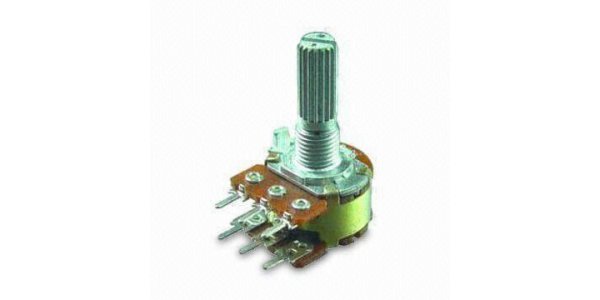

4. For the layout of adjustable components such as potentiometer, adjustable inductance coil, variable capacitor, micro switch, etc., the structural requirements of the whole wrench should be considered. Some switches often used should be placed in the place easily accessible by hands if the structure allows. The layout of components should be balanced, and the density should be appropriate, so that the top priority should not be attached to the top. The success of a product depends on its internal quality. But to take into account the overall beauty, both relatively perfect wrench, can become a successful product.

General order of placing components:

1. Place components closely matched with the structure, such as power socket, indicator light, switch, connector, etc.

2. Place special components, such as large components, heavy components, heating components, transformers, IC, etc.

3. Place small components.

Layout check:

1. Whether the size of the circuit board is consistent with the processing size required by the drawing.

2. Whether there are conflicts at all levels. For example, whether the level of components, outer frame and private printing is reasonable.

3. Whether the layout of components is balanced, arranged in order, and whether they have been completely distributed.

4. Whether the heat dissipation is good.

5. Whether the distance between thermal components and heating components is reasonable.

6. Whether the interference of the line needs to be considered.

7. Whether the commonly used components are convenient to use. Such as switches, plug-in board, plug-in equipment, components that need to be replaced frequently, etc.