1.0 The main material list of PCB board

1.1 Species introduction

Printed Circuit Board (PCB) are divided into three major categories by the number of layers: single layer panel, double layer panel, and multilayer printed circuit board. PCB can be divided into two categories according to character: Flexible printed circuit (FPC) and Flexible Printed Circuit Board (FPCB).

The single layer board is a circuit board with one side copper-clad and no copper-clad on the other side.

1.1.2 Double Layer PCB

The double board is a double-sided copper clad circuit board. And the two surfaces that are covered with copper are called the top layer and the bottom layer.

1.1.3 Multilayer PCB

The multilayer circuit board is a circuit board with multiple working layers. The board has a middle layer as well as a top and bottom layer. The middle layer can be composed of conductor layer, signal layer, power layer and connecting layer.

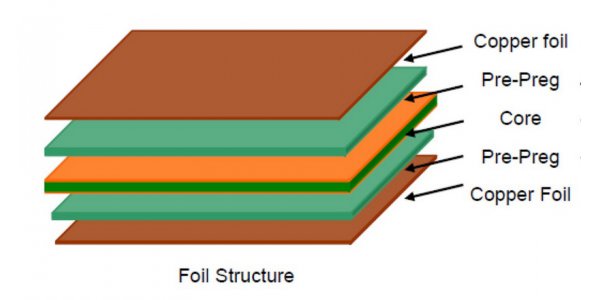

Therefore, in the general industrial production of raw materials mainly include copper clad laminate, copper foil, semi-cured sheet, chemical potions, dry film, printing ink, anodes (Copper, Tin and Nickel), etc. PCB raw materials of the board generally use insulating material of epoxy resin glass for the board. Designers usually use insulating cardboard to reduce costs, and cover the board with copper, which is PCB board.

1.2 Material introduction

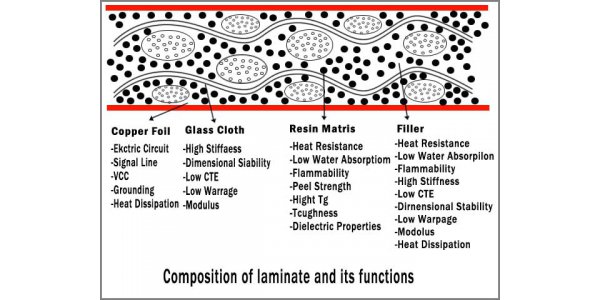

Materials used up and down the PCB include screen printing, solder, copper and substrate. The last of these layers is glass fiber that known as FR4 (flame retardant 4).

In general, only the thickness can be changed according to the purpose of the board. In a limited budget, some of the boards are made of phenolic or epoxy resin. Because of their thermal sensitivity, these boards tend to lose lamination easily. By contrast, they can also save a lot of money. Generally, through the smell produced by welding to distinguish the good or bad board material.

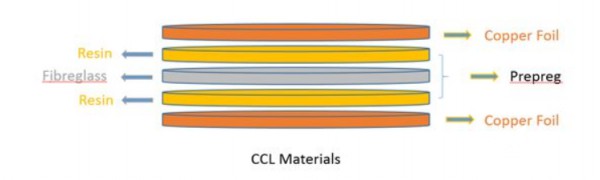

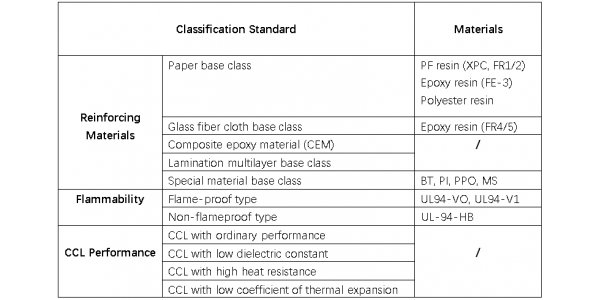

CCL(Copper-clad Laminate)can be divided into different categories according to different classification criteria. A brief classification of CCL is listed in the following table.

2.0 Conclusion

CCL is the more critical part of PCB. As a result, designers are likely to pay more attention to CCL fabrication techniques and materials. On the other hand, in order to continuously improve product quality, power consumption and stability, some new materials are also being discovered(GETEK, Megtron,Asahi Glass and so on).