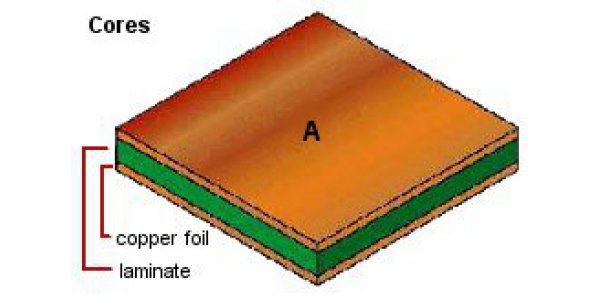

Copper clad laminate (CCL) is a kind of plate-like material, which is made by dipping electronic glass fiber cloth or other reinforced materials with resin, covering one or both sides with copper foil and hot pressing. Which is an extremely important basic material for printed circuit board (PCB). Various printed circuit boards with different forms and functions are selectively processed, etched, drilled and plated with copper to make different printed circuits (single, double and multi-layer).

As the substrate material in PCB manufacturing, copper clad laminate (CCL) plays an important role in the interconnection, insulation and support of PCB, and has a great impact on the transmission speed, energy loss and characteristic impedance of signals in the circuit. Therefore, the performance, quality, manufacturability, manufacturing level, manufacturing cost and long-term reliability and stability of printed circuit board (PCB) are discussed It depends largely on the CCL.

Copper clad laminate manufacturing industry is a sunrise industry. With the development of electronic information and communication industry, it has broad prospects for development. Its manufacturing technology is a high-tech with interdisciplinary, mutual penetration and mutual promotion. It is inseparable from the electronic information industry, especially with the printed circuit industry. Its progress and development has been driven by the innovation and development of electronic products, semiconductor manufacturing technology, electronic installation technology and printed circuit board manufacturing technology.

CCL has to go through many processes (such as drilling, electroplating, wiring, solder proof, etc.) to become PCB, PCB process is very long. As for the processing technology, we cannot use the same and different to measure and explain. Both PCB and CCL need to use hot and cold press to press copper foil and PP together to become CCL, while PCB is to press the inner circuit made by CCL with PP and copper foil together. In short, the circuit on the double-sided PCB is made by the circuit process (lamination exposure development etching) after the copper on the CCL is designed.

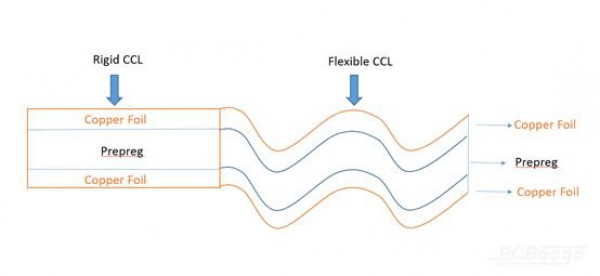

Generally speaking, CCL can be divided into rigid CCL and flexible CCL.

1) Rigid copper clad laminate

According to the different insulation materials and structures of CCL, it can be divided into organic resin CCL, metal based (core) CCL and ceramic based CCL. According to the thickness of CCL, it can be divided into conventional plate and thin plate. According to the reinforcement materials used in CCL, they can be divided into electronic glass fiber cloth based CCL, paper-based CCL and composite CCL. According to the copper clad laminate insulation resin division, then with a certain resin is called a resin copper clad laminate. Such as epoxy resin copper clad plate, polyester resin copper clad plate and cyanate ester resin copper clad plate and so on. In addition, there are special rigid copper clad laminates classified according to the flame retardant grade and some special properties.

2) Flexible copper clad laminate

At present, flexible copper clad laminates are divided into three types: polyester film type (flame retardant and non flame retardant), polyamide film type (flame retardant, non flame retardant, two-layer and three-layer method) and ultra-thin electronic glass fiber cloth type.