Aluminum pcb definition

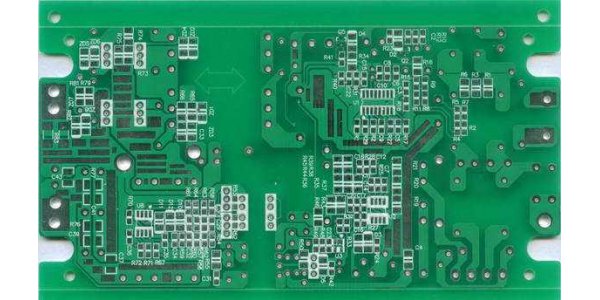

Aluminum PCB is a common metal-based copper-plated board. Aluminum PCB is composed of circuit layer, thermal insulation layer and metal bottom layer. The circuit layers are typically etched to form a printed circuit to interconnect the various components of the module. Because the circuit layer needs a large current-carrying capacity, a thicker copper foil should be used, and the thickness is generally 35 μm to 280 μm; the thermal insulation layer is the core of the aluminum PCB core technology. It usually consists of a special polymer filled with a special ceramic. Low heat resistance, excellent viscoelasticity, and resistance to thermal aging are its advantages.

Aluminum PCB Manufacturing Guide

Step One manufacture of aluminum PCB film:

Due to the presence of side corrosion, the accuracy of the drawing lines must be sufficient, so it is necessary to make certain process compensation when drawing the film negatively. The process compensation value must be based on measuring the side corrosion of different thickness Cu Value to confirm. The negative is negative.

Step two material preparation:

Try to acquire a 300 × 300mm fixed scale and a plate with a protective film on the Al surface and the Cu surface.

Step three the graphics:

the treatment of Cu surface is recommended to use chemical etching,the best effect. After the Cu surface is processed, the wet film is screen printed immediately after drying to prevent oxidation. After development, use a scale magnifier to measure whether the line width and gap meet the requirements of the drawing, and ensure that the line is smooth and without jagged. If the thickness of the UFO aluminum substrate is greater than 4mm, it is recommended to remove the transmission roller on the developing machine to prevent rework due to jamming.

Step four etching:

Corrosion using acid CuCl-HCl series solution. The solution was adjusted with an experimental plate, and the Al substrate was etched when the etching effect was the best,with the pattern side facing down to reduce the amount of side etching.

Step five surface treatment (Dip Sn):

After the etching process is completed, do not rush to remove the film, and immediately prepare a dip Sn solution, that is, remove the film, that is, dip Sn, the effect is the best.

Step six machining:

When processing the shape, a CNC milling machine should be used to separate the Teflon and aluminum substrate parts. This can avoid the delamination caused by the difference in thermal conductivity and deformation between the two. Face up to reduce delamination and burrs.

Characteristics of Aluminum PCB

(1)Use surface mount technology (SMT)

(2)Extremely useful treatment of thermal diffusion in circuit design schemes

(4)Reduce product size, reduce hardware and assembly costs

(5) Replace fragile ceramic substrate for better mechanical durability

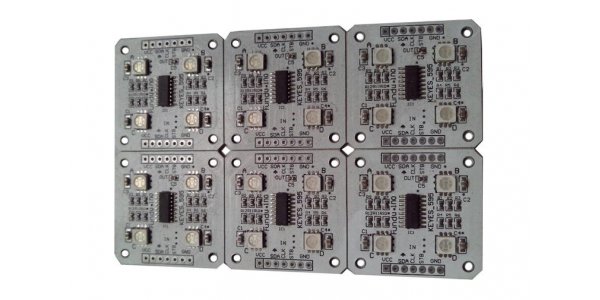

Structure of Aluminum PCB

Aluminum-based copper clad board is a metal circuit board material consisting of copper foil, thermally conductive insulating layer and metal substrate. Its structure is divided into three layers:(1)Cireuitl.Layer circuit layer: It is equivalent to the copper clad board of ordinary PCB.

(2)DielcctricLayer insulation layer: The insulation layer is a layer of low thermal resistance thermally conductive insulating material. Thickness: 0.003 "to 0.006" inches is the core location for aluminum-based copper clad laminates.

(3)BaseLayer: It is a metal substrate, usually aluminum or copper. Aluminum-based copper clad laminates and traditional epoxy glass cloth laminates.

Aluminum Pcb Use

Application: Power Hybrid IC (HIC).(1)Audio equipment: input, output amplifier, balanced amplifier, audio amplifier, preamplifier, power amplifier, etc

(2)Power supply equipment: switching regulator, DC / AC converter, SW regulator, etc

(3)Communication electronic equipment: high-frequency amplifiers, filter appliances, and transmission circuits

(4)Office automation equipment: motor driver, etc

(5)Car: electronic regulator, igniter, power controller, etc

(6)Computer: CPU board, floppy disk drive, power supply unit, etc.

(6) Power module: converter, solid state relay, rectifier bridge, etc.

Discussion of Early Packaging

Early packaging methods, see the outdated shipping packaging methods in the table, detailing their missing. There are still some small factories that use these methods for packaging.The domestic PCB capacity expansion is extremely fast, and most of them are exported. Therefore, the competition is very fierce. Not only the competition between domestic factories, but also the first two major US and Japanese PCB factories. Besides being affirmed by customers, the quality of packaging must be satisfied by customers. Almost a certain scale electronics factory will now require PCB manufacturers to ship the packaging, you must pay attention to the following items, some even directly give specifications for shipping packaging.

(2)The number of plates per stack is limited depending on the size.

(3)Specifications for the tightness of each PE film coating and the width of the margin.

(4)Specifications of PE film and Air Bubble Sheet.

(5)Carton pound size specifications and others.

(6)Are there any special provisions for placing buffers before placing boards inside the carton?

(7)Resistance rate specification after sealing.

(8)Limited weight per box.

At present, Vacuum Skin Packaging in China is similar. The main differences are the effective working area and the degree of automation.

Vacuum Packaging

Operating procedure(1)Preparation: Position the PE film, manually check whether the mechanical action is normal, set the PE film heating temperature, vacuum time, etc.

(2)Stacking board: When the number of stacked boards is fixed, its height is also fixed. At this time, how to stack can be considered to maximize output and save materials. Here are a few principles:

a. The distance between each stack of boards, depending on the specifications (thickness) of the PE film (the standard is 0.2m / m), using its principle of heating and becoming soft and stretched, while vacuuming, covering the boards and sticking to the bubble cloth . The spacing is generally at least twice the total thickness of each stack. If it is too large, it will waste material; if it is too small, it will be difficult to cut and it will fall off easily or cannot be adhered at all.

B. The distance between the outermost plate and the edge must also be at least double the thickness of the plate.

C. If the size of PANEL is not large, materials and manpower will be wasted according to the above packaging method. If the quantity is very large, it can also be opened as a container similar to the flexible board packaging method, and then made into PE film shrink packaging. There is another way, but it is necessary to obtain the customer's consent. There is no space between each stack, but it is separated by cardboard, and the appropriate stack number is taken. There is also cardboard or corrugated paper underneath.

(3)Start-up: A. Press start-up. The heated PE film will be lowered by the pressure frame to cover the table surface. B. Then the bottom of the vacuum pump will be sucked in to close the circuit board and stick to the bubble cloth. C. After the heater is removed to cool it, raise the outer frame. D. After cutting off the PE film, pull the chassis apart to cut each stack separately.

(4)Packing: The packing method, if specified by the customer, must be in accordance with the customer's packing specifications; if the customer does not specify, the packaging specifications in the factory must also be established on the principle of protecting the board from being damaged by external forces, precautions As mentioned earlier, the packaging of products, especially for export, must be given special attention.

(5)Other matters needing attention:

A. Information that must be written outside the box, such as "mouth wheat head", material number (P / N), version, period, quantity, and important information. And the words Made in Taiwan (if exported).

B. Attach the relevant quality certificates, such as sectioning, solderability report, test records, and some customer-required test reports, and place them in the manner specified by the customer.

Pcb board packaging is not a complicated thing, we only need to do a good job of packing every detail, so we can effectively avoid unnecessary trouble in the later stage.

The above is the aluminum PCB production guide and some usage tips. Our company has many years of experience in the production and production of aluminum pcb boards. If necessary, please contact us.