How to accurately select the appropriate material products according to the actual situation and the specific quotation budget information will not only affect the cost expenditure in the early stage, but also play a decisive role in the actual use effect of users in the later stage to a certain extent. So today's information for you is about the performance of aluminum pcb, including its basic popularization information, as well as its advantages and features and suitable application of the plate content, we can take this to have a better understanding of it.

1.Performance introduction of aluminum PCB

Aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre drawing process. Although its strength cannot be compared with that of 2XXX system or 7xxx system, its magnesium and silicon alloy have many characteristics, such as excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness, no deformation after processing, compact and defect free material, easy polishing, easy coloring film, and extremely oxidation effect Excellent features.

1).The application of strip is widely used in decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and other industries.

2).Aluminum materials for aerospace are used to make aircraft skin, fuselage frame, girder, rotor, propeller, fuel tank, wall plate and landing gear pillar, as well as rocket forging ring, spacecraft wall plate, etc.

3).Aluminum materials for transportation are used for car body structure materials of automobiles, metro vehicles, railway passenger cars and high-speed passenger cars, car doors and windows, shelves, auto engine parts, air conditioners, radiators, body panels, hubs and ship materials.

4).Packaging aluminum all aluminum cans are mainly used as metal packaging materials in the form of sheet and foil, which are made into cans, lids, bottles, barrels and packaging foil. Widely used in beverage, food, cosmetics, drugs, cigarettes, industrial products and other packaging.

5).Aluminum material for printing is mainly used for making PS plate. Aluminum based PS plate is a new material for printing industry, which is used for automatic plate making and printing.

6).Because of its good corrosion resistance, sufficient strength, excellent process performance and welding performance, aluminum alloy for building decoration is mainly used in building frame, doors and windows, ceiling, decorative surface, etc. Such as all kinds of building doors and windows, curtain wall with aluminum profiles, aluminum curtain wall plate, profiled plate, decorative plate, color coated aluminum pcb, etc.

7).Aluminum materials for electronic home appliances are mainly used in various fields such as bus, stringing, conductor, electrical component, refrigerator, air conditioner, cable, etc. Specification: round bar and square bar are used for aerospace fixed device, electrical fixed device and communication field. As a relatively important material product, 6061 aluminum pcb plays a very important role in many places. So the above explains the reasons for this, including the advantages and characteristics of 6061 aluminum pcb and professional interpretation of performance parameters, and in addition, it also includes common application fields and ranges, etc. for those who are interested in purchasing related materials, it is extremely necessary to know in advance, which can help us save a lot of costs.

2.Advantages of aluminum pcb:

The advantages of aluminum PCB are lightweight material, reducing the load of the building and providing good selection conditions for high-rise buildings; excellent waterproof, antifouling and anti-corrosion performance, ensuring that the external surface of the building is long and new; processing, transportation, installation and construction are relatively easy to implement; high performance price ratio, easy maintenance, long service life.

Main advantages:

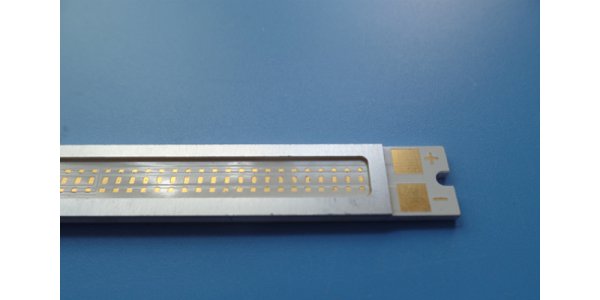

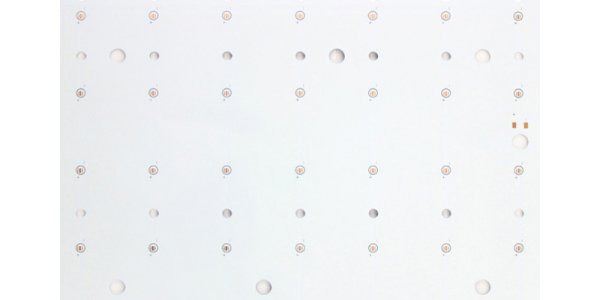

Aluminum pcb (metal base heat sink (including aluminum base plate, copper base plate and iron base plate)) is a low alloyed Al Mg SI system high plasticity alloy plate (structure is shown in the figure below), which has good thermal conductivity, electrical insulation and machining performance. Aluminum pcb and traditional FR-4 Compared with the same thickness, the same linewidth, aluminum substrate can carry higher current, aluminum substrate withstand voltage can reach 4500V, thermal conductivity is greater than 2.0, aluminum PCB is the main industry.

● adopt surface mounting technology;

● in the circuit design scheme, the heat diffusion is effectively treated;

● reduce the operating temperature of the product, improve the power density and reliability of the product, and extend the service life of the product;

● reduce product volume and hardware and assembly cost;

● replace fragile ceramic substrates for better mechanical durability. structure

Aluminum based copper clad plate is a kind of metal circuit board material, which is composed of copper foil, thermal insulation layer and metal base plate. Its structure is divided into three layers:

Cireuitl.layer circuit layer: equivalent to the copper clad plate of ordinary PCB, the thickness of circuit copper foil is from LOZ to 10oz.

Dielcctriclayer insulating layer: the insulating layer is a layer of low thermal resistance heat conducting insulating material.

Thickness: 0.003 "to 0.006" inch is the core technology of aluminum-based copper clad plate, which has been UL certified.

Baselayer base: it is a metal base plate, generally aluminum or optional copper. Aluminum based copper clad laminates and traditional epoxy glass cloth laminates.

3.Application and classification of Aluminum PCB:

While power converters and LEDs are the largest users of these products, automotive and RF companies also want to take advantage of these products. While single tier architecture is the simplest, other configuration options are available at amitron, including:

Flexible Aluminum PCB:

One of the latest developments in IMS materials is flexible dielectrics. These materials have a polyimide resin system with ceramic fillers, providing excellent electrical insulation, flexibility and, of course, thermal conductivity. When applied to flexible aluminum materials such as 5754 or similar, products can be formed to achieve various shapes and angles, which can eliminate expensive fixtures, cables and connectors. Although these materials are flexible, they are designed to bend into place and remain in place. They are not suitable for applications that are bent periodically.

Mixed aluminum pcb:

In the "hybrid" IMS structure, the "sub assemblies" of non thermal materials are treated independently, and then amitron hybrid IMS PCBs are bonded to the aluminum substrate with a thermal material. The most common structure is a 2-tier or 4-tier sub assembly made from a traditional FR-4. Bonding the layer to an aluminum substrate with a thermoelectric medium can help to dissipate heat, improve rigidity and act as a shield. Other benefits include:

Lower cost than building all heat conducting materials

Provides better thermal performance than standard FR-4 products

Expensive radiators and associated assembly procedures can be eliminated

It can be used in RF applications requiring RF loss characteristics of PTFE surface layer.

Use the assembly window in aluminum to accommodate the through hole assembly. This allows the connector and cable to pass the connector through the substrate while welding the fillet to produce a seal without the need for special washers or other expensive adapters.

Multilayer Aluminum PCB:

In the high-performance power supply market, multilayer IMS PCB is made of multilayer conductive dielectric. These structures have one or more layers of circuits embedded in the dielectric, and the blind hole is used as a hot through hole or a signal path. Although it is more expensive and less efficient to transmit heat in a single-layer design, they provide a simple and effective cooling solution for more complex designs.

Through hole Aluminum PCB:

In the most complex structure, a layer of aluminum can form a "core" of multilayer thermal structure. Prior to lamination, aluminum is electroplated and filled with dielectric. Thermal materials or sub assemblies can be laminated to both sides of aluminum using a thermal bonding material. Once laminated, the finished components are similar to the traditional multi-layer aluminum pcb through drilling. Electroplated through holes pass through gaps in aluminum to maintain electrical insulation. Alternatively, the copper core may allow direct electrical connection as well as insulating through holes.