COB Process Introduction and Precautions

Posted: May 14, 2022

By: Bonnie

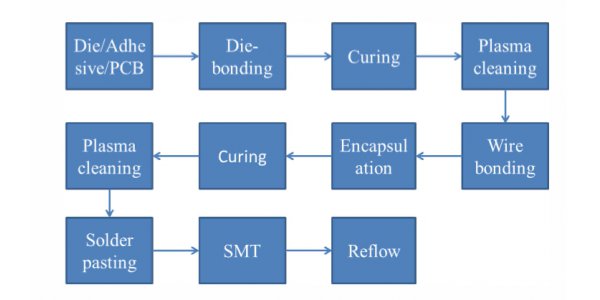

COB (Chip on Board) is a method of directly attaching a bare die to a circuit board, and directly bonding the wire to the gold-plated circuit of the PCB. Then, the IC packaging step is transferred to the circuit board through the sealing technology.

The evolution history of electronic chip packaging is from IC packaging → COB → Flip Chip (COG), and the size is getting smaller and smaller. In the past, COB technology was generally used in consumer electronics products that did not pay much attention to reliability, such as toys, calculators, small displays, clocks and other daily necessities, because most manufacturers that make COBs generally consider Low Cost. Nowadays, more and more manufacturers value its small size and the trend of thin, light and short products, and there is an increasing trend in its use, such as mobile phones and other short-required products.

COB has another advantage that makes some PCBA processors particularly fond of it. Due to the need for sealing, ordinary COBs will seal all external lead pins in epoxy resin. For those hackers who like to crack other people's designs, it may take more time due to this feature. To crack, indirectly to improve the level of anti-hacking security.

2. Environmental requirements for COB

It is recommended to have a clean room and the class should be below 100K. Because the COB process belongs to the wafer packaging level, any small particles contaminating the solder joint will cause serious defects.

Basic dust-free clothing is also necessary. It is not necessary to wrap the head into a meat-like dust-free clothing, but basic hats, clothes, and electrostatic shoes are all required.

In addition, the clean room should strictly control the entry of cardboard boxes and any items that are easy to carry or generate debris. All packages should be unpacked before entering the clean room. This is to keep the clean room clean and extend the life of the clean room.

3. PCB design requirements for COB

3.1. The surface treatment of the finished PC board must be gold-plated, and it must be thicker than the gold-plated layer of ordinary PC boards, in order to provide the energy required for Die Bonding to form gold-aluminum or gold-gold co-gold.

3.2. As far as the layout of the pads outside the COB's Die Pad is concerned, try to keep the length of each bonding wire fixed, that is, the distance from the die to the PCB pads should be the same. Therefore, the design of diagonal pads does not meet the requirements. It is recommended that the PCB pad pitch be shortened to eliminate the appearance of diagonal pads.

3.3. It is recommended to have at least two positioning points for a COB wafer. We hope to use the cross-shaped positioning points instead of the traditional circular positioning points, because the Wire Bonding machine will grasp the straight line for positioning when it performs automatic positioning. . There may be some Wire Bonding machines that are not the same. It is recommended to refer to the performance of the machine to make a design first.

3.4. The size of the PCB's (Die Pad) should be larger than the actual die to limit the offset when placing the wafer, but it should not be too large to avoid the wafer from rotating too much. It is recommended that the wafer pads on each side be 0.25 ~ 0.3mm larger than the actual wafer.

3.5. It is best not to arrange vias in the area where the COB needs to be glued. If it cannot be avoided, these vias must be 100% completely plugged to prevent Epoxy glue from penetrating the other side of the PCB.

4. Silver glue

If the wafer has ground or heat dissipation requirements, silver glue is generally used, if not, anaerobic glue is used. As the name suggests, anaerobic adhesive is to block it from contacting with the air, and it will cure naturally without high temperature baking. The use of silver glue requires high temperature baking to solidify. There are two types of baking temperature and time: 120 ° C for 2 hours, and 150 ° C for 1 hour.

When choosing silver glue and anaerobic glue, pay attention to it: anaerobic glue cannot conduct electricity and conduct heat. Pay attention to its life when using. The reliability of anaerobic adhesives needs further review, and attention should be paid to the possibility of remelting.

5. Die adhesion

Most common COB factories belong to Low Cost, so most of them use manual mode to produce COB. Another reason is that a small amount of diverse production is not suitable for automation. There are two ways to manually pick up the die and stick it to the die pad of the PCB:

5.1. Use a small vacuum pen: This type of vacuum pen is more suitable for large-sized wafers. Because the front end has a circular rubber pad, wafers that are too small will be completely covered by the rubber pads, which will affect the placement of wafers. Correctness. Also note that the metal vacuum tube cannot directly contact the wafer surface to avoid scratching the wafer.

5.2. Use silicone: suitable for small size wafers. Generally, the tip of the toothpick is coated with silicone, which can be used to stick small-sized wafers to a solder pad coated with silver glue. The silver glue will stick the wafer to achieve the purpose of sticking.

The silver glue applied to the pads must ensure that it adheres to 70 ~ 100% of the wafer area to ensure that the wafer does not move in the post-process. It should be noted that the silver glue should not overflow the area of the wafer to avoid contaminated solder joints. Generally, the maximum bonding rotation angle of the wafer allowed by the automatic Wire Bonding Machine is 8 ~ 10 °, while the manual wire bonding machine can allow a maximum angle of 30 °.

Wafer storage: Generally, wafers from wafer manufacturers use vacuum moisture-proof packaging. If the wafer has been unpacked, pay attention to the dust contamination that cannot be exposed, and the wafer surface should not be touched by metal objects. The unsealed wafers can be repackaged in vacuum or stored in a nitrogen cabinet to avoid oxidation and any contamination.

6. Welding wire

According to the shape of the solder joints, the welding process can be divided into ball bonding and wedge bonding. COB usually uses aluminum wire (Al wire) so it is Wedge Bond. Ball welding is stronger and more expensive than wedge welding.

COB generally requires a manual welding machine to repair the welding wire, because the automatic machine is too expensive, if you stop to repair it will affect the output. It is generally not recommended to use PCB as the plywood, because the Wire Bonding machine has a maximum size limit, and the moving range of the Wire Bonding welding head is limited to 4 "x4". If you want to hit more than two COBs at the same time, you must Pay special attention. The COB process capability can reach a solder joint distance of 90um, but the general COB can accept a solder joint distance of 100 ~ 140um. The COB process generally only measures wire pull.

7. Epoxy resin sealant

7.1. Most COB manufacturers use manual dispensing, because COB belongs to Low Cost, but manual dispensing has the possibility of damaging the welding wire and the disadvantages of inconsistent dispensing shapes.

7.2. The viscosity of epoxy resin is very important.

7.3. Using an automatic dispenser will help control the cured shape of the COB epoxy resin.

7.4. Some epoxy resins need to use preheated needles, because the epoxy resin will reduce the viscosity for a period of time after heating, which will help the epoxy resin to flow and reduce the possibility of wire pulling. The recommended preheat temperature for epoxy resin is 60 +/- 5 ° C, and the preheat temperature for PCB is 80 ° C.

7.5. If the wafer pitch is relatively small (Fine Pitch), it is recommended to use a relatively low viscosity epoxy resin and use a dam (Dam) ring on the periphery to block the epoxy resin from flowing around.

7.6. COB coating thanks to its quality: air foam, wire failure rate

7.7. The curing time should be considered. Heal at 120 degrees Celsius for 2 hours, and 150 degrees Celsius for 1 hour. KHH curing time is (80 ℃ + 1hrs) + (110 ℃ + 2hrs)

7.8. You can choose Epoxy mixed with OK, but it should be refrigerated at low temperature.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

9

)

9

1824

1

Share to: