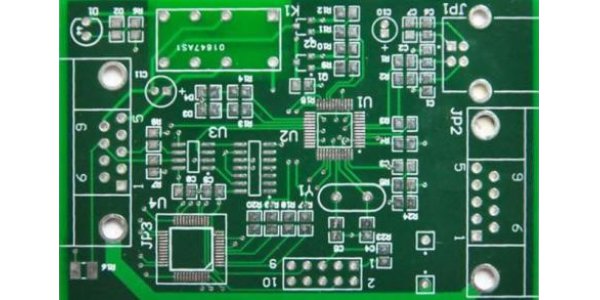

Printed circuit board is an important electronic component, the support of electronic components and the carrier of electrical connection of electronic components.Printed circuit board is divided into flexible circuit board and rigid circuit board according to different materials.

Rigid Flex PCB Introduction

Flexible printed board.It is a printed circuit board with high reliability and high flexibility, which is based on polyimide or polyester film.Rigid printed boards include phenolic paper laminate, epoxy paper laminate, polyester glass felt laminate and epoxy glass cloth laminate.

Flexible PCB is a kind of printed circuit with high reliability and excellent flexibility, which is made of polyester film or polyimide as the base material. Through the circuit design embedded in the flexible light plastic sheet, a large number of precision components are embedded in the narrow and limited space, thus forming a flexible circuit. The circuit can be bent at will, folded light, small size, good heat dissipation, easy to install, breaking through the traditional interconnection technology. In the structure of flexible circuit, the materials are insulating film, conductor and adhesive.

The Features of Rigid PCB

1. High density.

2. High reliability - through a series of checks, tests and aging tests, it can ensure the long-term and reliable use of PCB.

3. Designability. For PCB performance (electrical, physical, chemical, mechanical, etc.), PCB design can be realized through design standardization, standardization, etc., with short time and high efficiency.

4. Producibility. With modern management, standardization, scale (quantity), automation and other production can be carried out to ensure the consistency of product quality.

5. Testability. A relatively complete test method, test standard, various test equipment and instruments are established to test and identify PCB product qualification and service life.

Compared with the functions and main materials of rigid pcb and flexible PCB, the difference between them is still great. One is applied to light industry and electronic equipment industry, and the other is applied to industry and electronic industry which need high stability. Therefore, for the characteristics and main application scope of these two kinds of PCBs, the main functions of rigid pcb and flexible PCB should be based on the industrial circuit board Always use.Flexible printed circuit board is also known as FPC. Flexible printed circuit board is a kind of printed circuit board with high reliability and high flexibility, which is based on polyimide or polyester film. This kind of circuit board has good heat dissipation, which can be bent, folded and twisted, and can be moved and expanded at will in three-dimensional space. FPC can be used to reduce the volume, realize lightweight, miniaturization and thinness, so as to realize the integration of component device and wire connection. FPC is widely used in electronic computer, communication, aerospace, home appliances and other industries.

Flexible circuit board products are small in volume and light in weight, which greatly reduces the volume of the device. It is suitable for the development of electronic products in the direction of high density, miniaturization, lightweight, thinness and high reliability. With high flexibility, it can be freely bent, wound, twisted, folded, and three-dimensional wiring. According to the requirements of spatial layout, it can be arranged and changed shape, and can move and expand freely in three-dimensional space, so as to achieve the integration of component assembly and wire connection.

Application:

Flexible PCB in PCB is mainly suitable for consumer electronics industry, such as mobile phone, display module, camera module, hard disk, etc. But according to the development and application of 5g mobile phone, the application of flexible PCB will be more widely used. The rigid pcb is mostly used in communication industry, such as communication board. The radio frequency part of the communication board is relatively high, and the digital signal rate of the baseband part is very high, which leads to very high material requirements. Some parts also need to use ceramic substrate plates. In terms of processing, the number of layers of circuit board is mostly about dozens, and back drilling and other technologies are also needed. Therefore, the function of rigid pcb for communication industry is better than that of flexible PCB.

Flexible PCB can withstand extreme temperature: between - 200 ° and 400 ° which is why flexible PCB can be used for drilling measurement in natural gas and oil industry. Due to the above conditions, the equipment needs to be resistant to extreme temperature, so it has radiation resistance, UV linear resistance and chemical resistance. So combining the high controllability and flexibility of high-density circuit board is of great benefit to most manufacturing industries.

The flexible circuit board has remarkable characteristics in reducing volume. In the assembly and connection of components, the conductor section of the flexible circuit board is flat and thin compared with the conductor cable, reducing the conductor size and forming along the shell, making the mechanism of the equipment more compact and reasonable, and reducing the installation volume. Compared with the rigid circuit board, the space can be saved by 60-90%.